Protective clothing performance test system and using method thereof

A technology for testing systems and protective clothing, which is used in testing wear resistance, using liquid/vacuum for liquid tightness measurement, measuring devices, etc. Reduce space and avoid the effect of lax closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

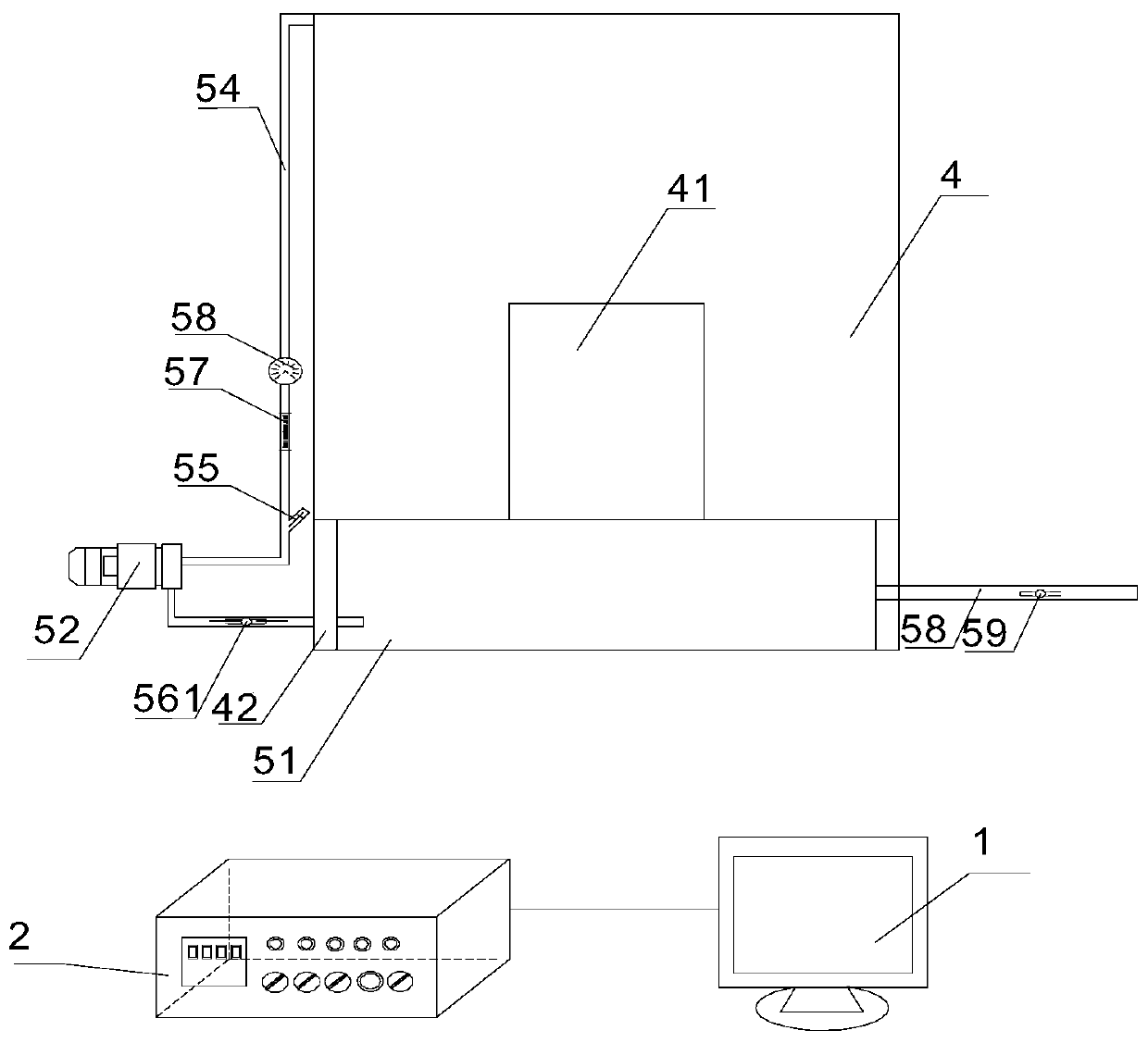

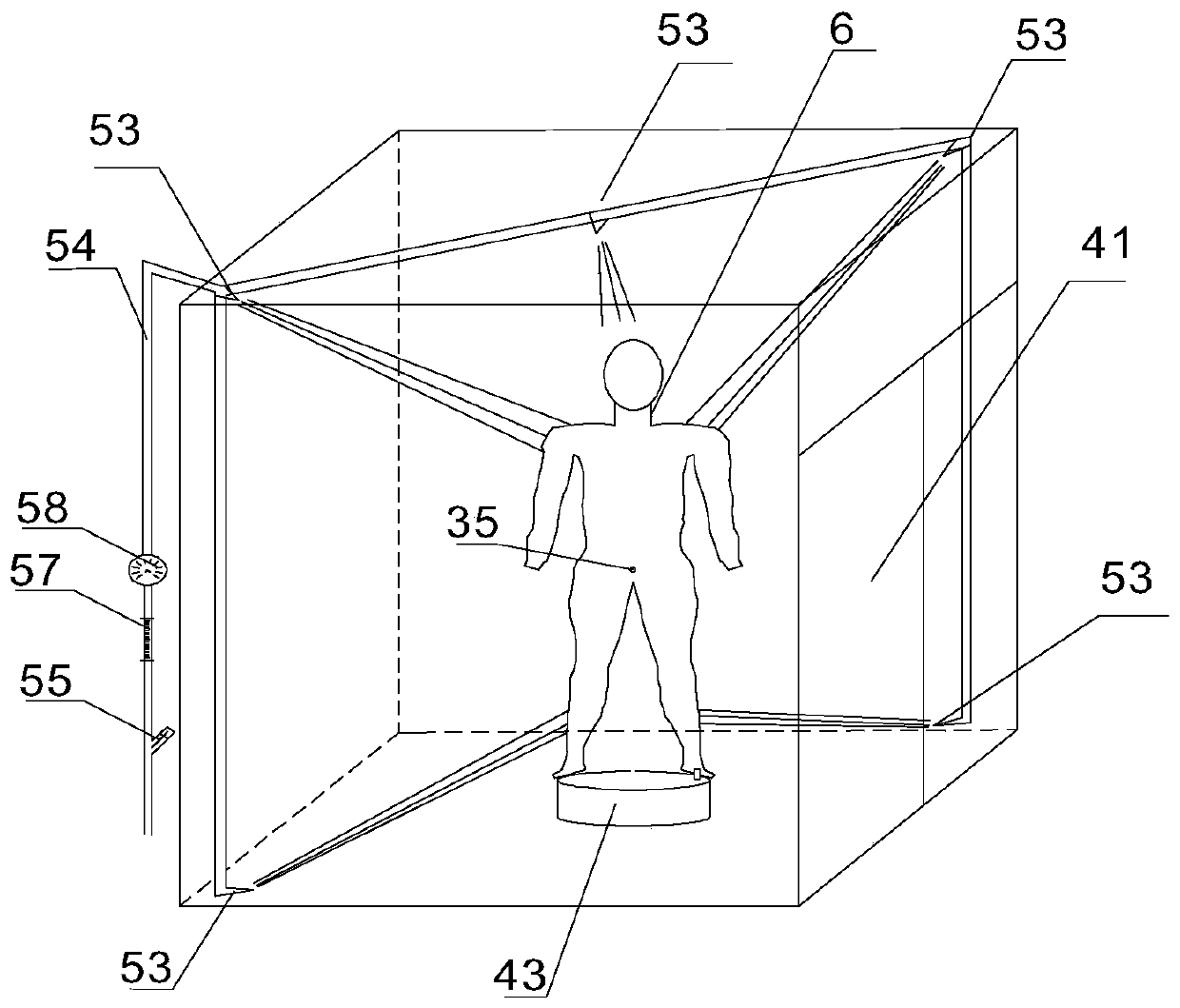

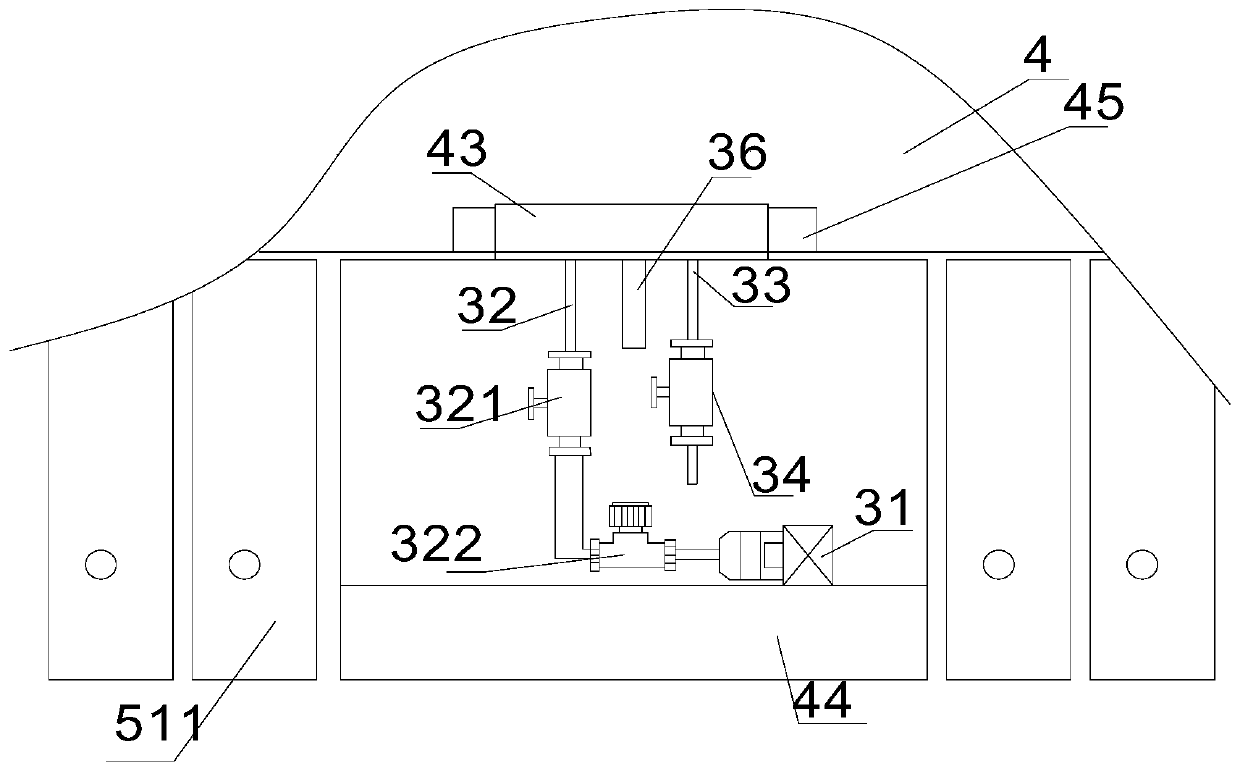

[0052] Such as Figure 1-4As shown, a protective clothing performance testing system includes a control device, an air tightness testing device, a spray testing device, and a test chamber 4, and a support for supporting the protective clothing 6 is arranged in the test chamber 4. In this embodiment , the supporting part uses a dummy model, which is made of metal winding, so as to support the protective clothing 6 and ensure the gas flow in the entire protective clothing 6. The test chamber 4 can prevent the explosion of the protective clothing 6 due to improper operation during the airtight test, and can prevent the external environment from being damaged during the spray test. A door 41 is set on the test chamber 4, which is convenient to prevent the protective clothing 6, and a sealing strip is provided on the contact surface between the door 41 and the test chamber 4 when it is closed. The airtightness testing device and the jetting testing device are respectively describe...

Embodiment 2

[0069] Concrete steps when using the airtightness testing device in embodiment 1 to detect protective clothing 6 are as follows:

[0070] SA1, the protective clothing 6 is arranged on the support member, the air inlet valve of the protective clothing 6 is connected with the output end of the air inlet pipeline 32 in a sealed manner, the air outlet valve and the input end of the air outlet pipeline 33 are conducted and the edges are sealed; the pressure sensor 35 The detection end of the pressure sensor is sealed and arranged in the protective clothing 6, and is connected to the signal output end of the pressure sensor 35 and the control device;

[0071] SA2, start the inflation stage, the control device controls the air pump 31 to open, the intake on-off valve 322 in the intake valve group is opened, the numerical control proportional valve 321 is in a state of large flow, the leak on-off valve 34 on the outlet pipeline 33 is closed, and the pressure The data detected by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com