Paint gun service life testing device

A technology for life testing and spray guns, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as lack of testing, connection degree testing of wrenches and spray guns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

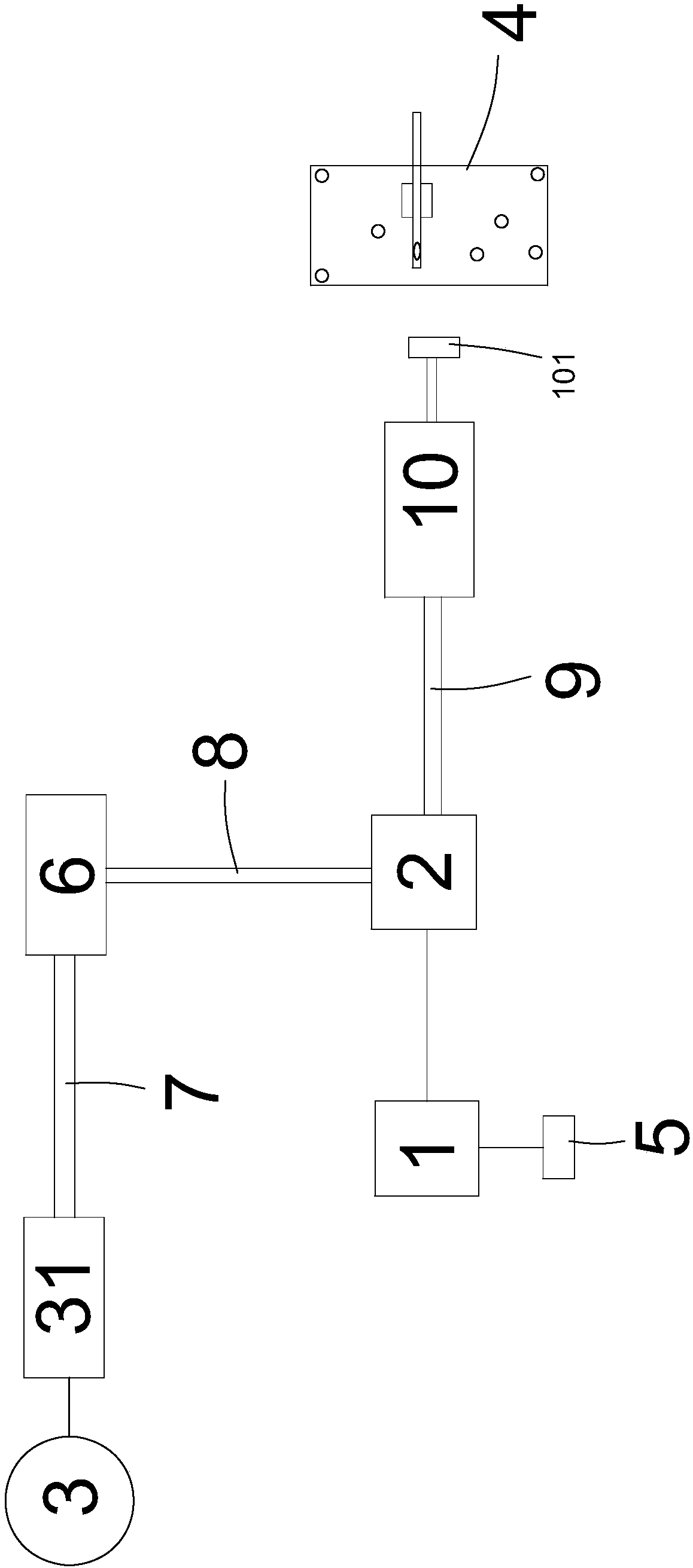

[0038] Such as figure 1 As shown, the present embodiment is a kind of spray gun service life testing equipment, including installation platform;

[0039] A microcomputer counter 1 is set on the installation platform in the manner of controlling the action of the solenoid valve 2;

[0040] A solenoid valve 2 is set on the installation platform in a manner of driving the cylinder arm 101 of the cylinder 10 to do telescopic movement;

[0041] The gas source 3 is connected to the solenoid valve 2 in a manner of ventilating the solenoid valve 2; the output end of the gas source 3 is provided with a gas source processing pressure regulating valve 31 in a manner of controlling the gas source 3 to ventilate to the solenoid valve 2;

[0042] The paint spray gun fixture 4 is arranged on the installation platform near the cylinder 10 side by fixing the paint spray gun and making the cylinder arm 101 protruding from the cylinder 10 push the wrench of the paint spray gun fixedly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com