Micro capillary electrophoresis chip and preparation method thereof

A microcapillary, electrophoresis chip technology, applied in chemical instruments and methods, material analysis by electromagnetic means, laboratory containers, etc. Reduce inspection cost and improve integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

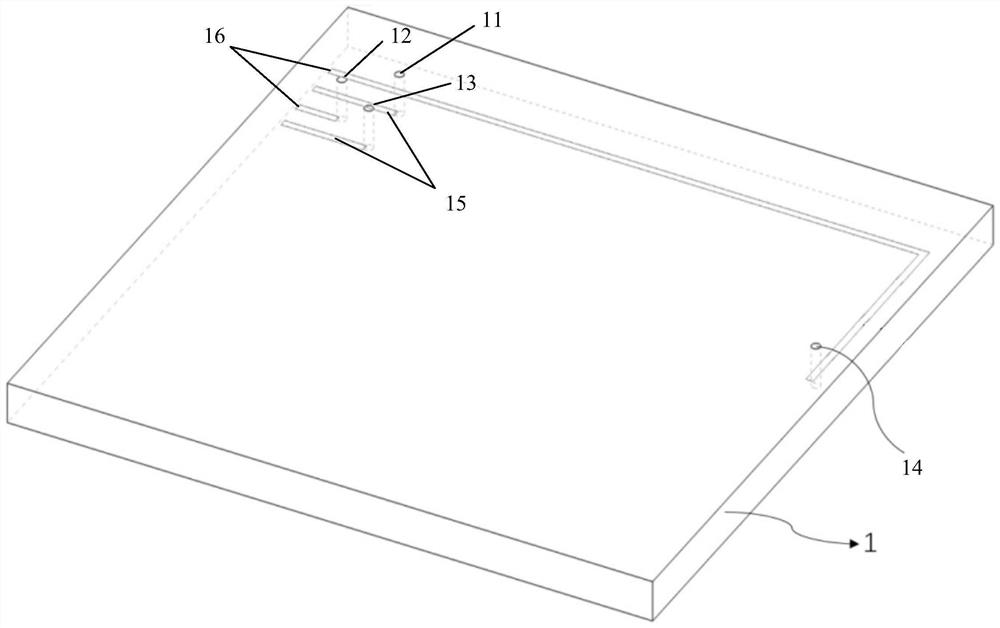

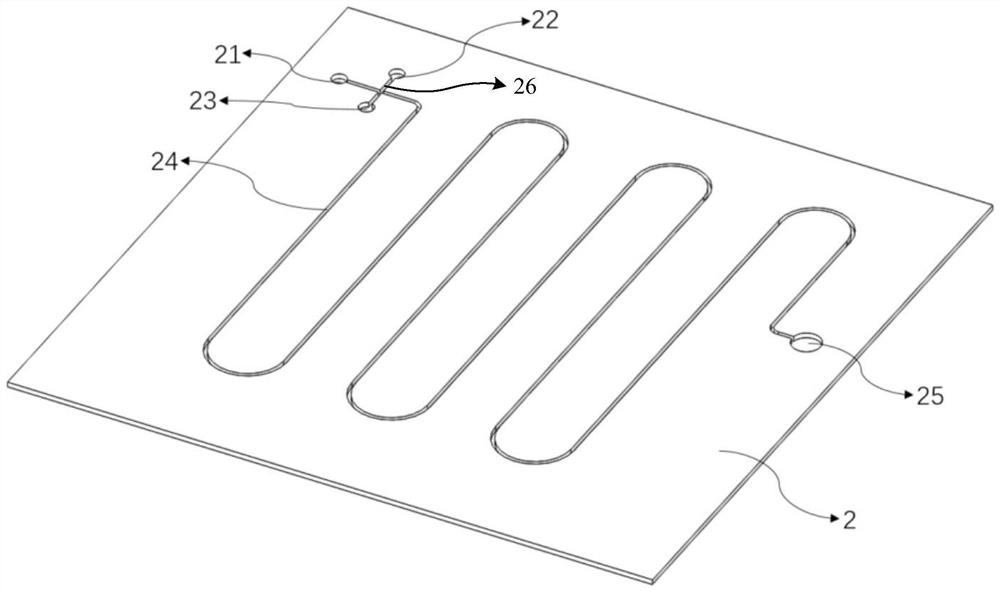

[0050] Such as figure 1 A schematic diagram of the structure of the first layer of the microcapillary electrophoresis chip in one embodiment shown, figure 2 A schematic diagram of the second layer structure of the microcapillary electrophoresis chip in one embodiment of the present invention is shown, image 3 A schematic diagram of the third layer structure of the microcapillary electrophoresis chip in one embodiment of the present invention is shown, Figure 4 Shown is a schematic diagram of the bonding of the first layer structure, the second layer structure and the third layer structure of the microcapillary electrophoresis chip in one embodiment of the present invention.

[0051] combine Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a microcapillary electrophoresis chip includes a first layer structure 1, at least one group of micro metal electrodes is arranged on the lower surface of the first layer structure, and at least one liqu...

Embodiment 2

[0078] The difference between this embodiment and the first embodiment is that the silicon chip of the CMOS CMOS detection circuit of the CMOS image sensor is processed on the surface to form micro-channels.

[0079] According to an embodiment of the present invention, a microcapillary electrophoresis chip includes a first layer structure, at least one group of micro metal electrodes is arranged on the lower surface of the first layer structure, and at least one liquid inlet hole and one liquid outlet are opened through the first layer structure hole.

[0080] In some embodiments, a first liquid inlet hole and a second liquid inlet hole are opened through the first layer structure, and a first liquid outlet hole and a second liquid outlet hole are opened through the first layer structure. The first group of micro metal electrodes and the second group of micro metal electrodes are arranged on the lower surface of the first layer structure.

[0081] According to an embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com