Arc extinguishing chamber actuator applied to isolation load switch

A technology of actuators and load switches, applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of slow current closing speed and achieve the effect of fast closing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

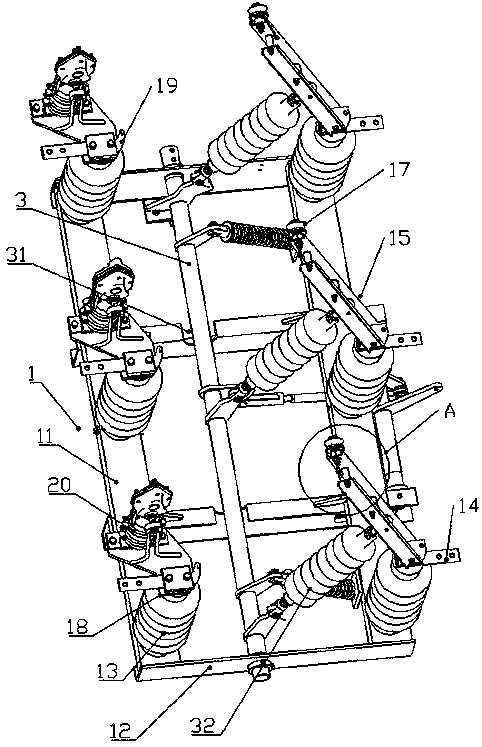

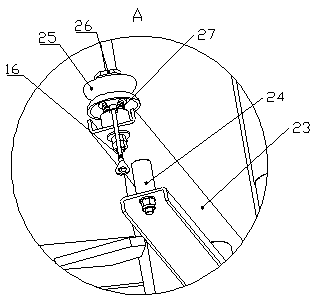

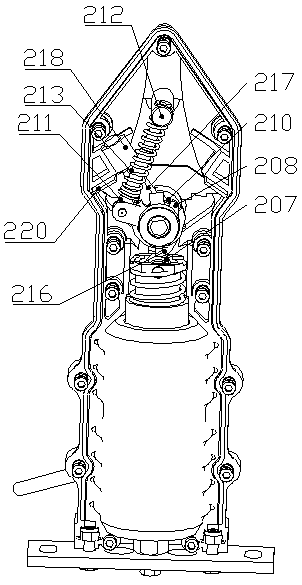

[0026] like Figure 1-Figure 4 An interrupter actuator for an isolating load switch is shown, including

[0027] A base 1, the base 1 is a cuboid frame structure composed of a pair of longitudinal bars 11 and four cross bars 12, wherein the two outermost bars 12 are fixedly connected to the outer sides of the longitudinal bars 11, and the two inner sides are A horizontal bar 12 is connected and fixed to the bottom of the vertical bar 11. In this embodiment, the vertical bar 11 and the horizontal bar 12 all adopt a U-shaped channel steel structure, so that the structure of the entire base 1 is more stable.

[0028] Several sets of insulator groups installed on the longitudinal rods 11, each group of insulator groups is composed of a pair of insulators 13 installed on two lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com