Imbricated battery string production equipment

A technology for production equipment and batteries, which is applied in the direction of circuits, electrical components, conveyor objects, etc., can solve the problems of low efficiency, large volume of stacking machines, and small occupied space, so as to improve production efficiency, reduce equipment costs, and reduce occupancy effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0058] The invention is a production equipment for shingled battery strings, which is used for breaking large battery slices into small battery slices, and then shingling and stacking a predetermined number of battery slices to form a battery slice string. Further, in the present invention, the battery slice string can also be made into a shingled battery string.

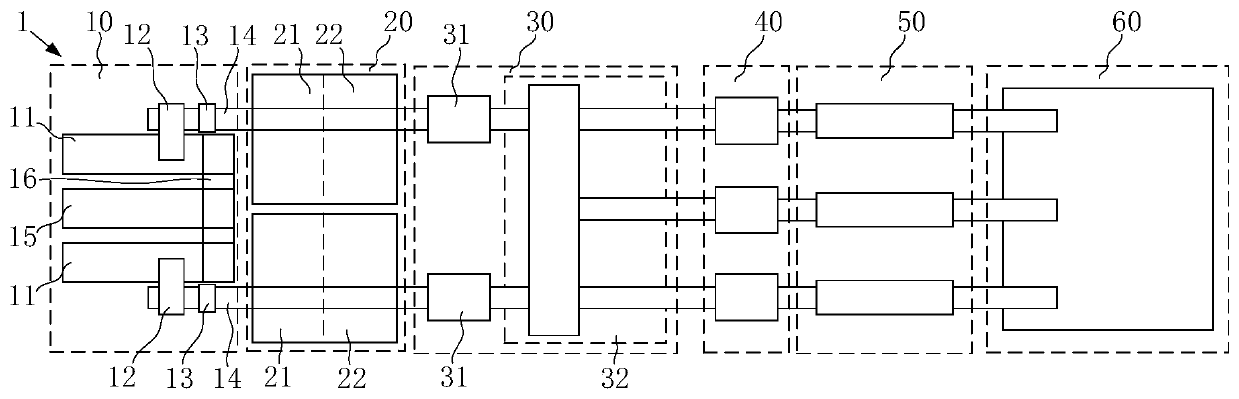

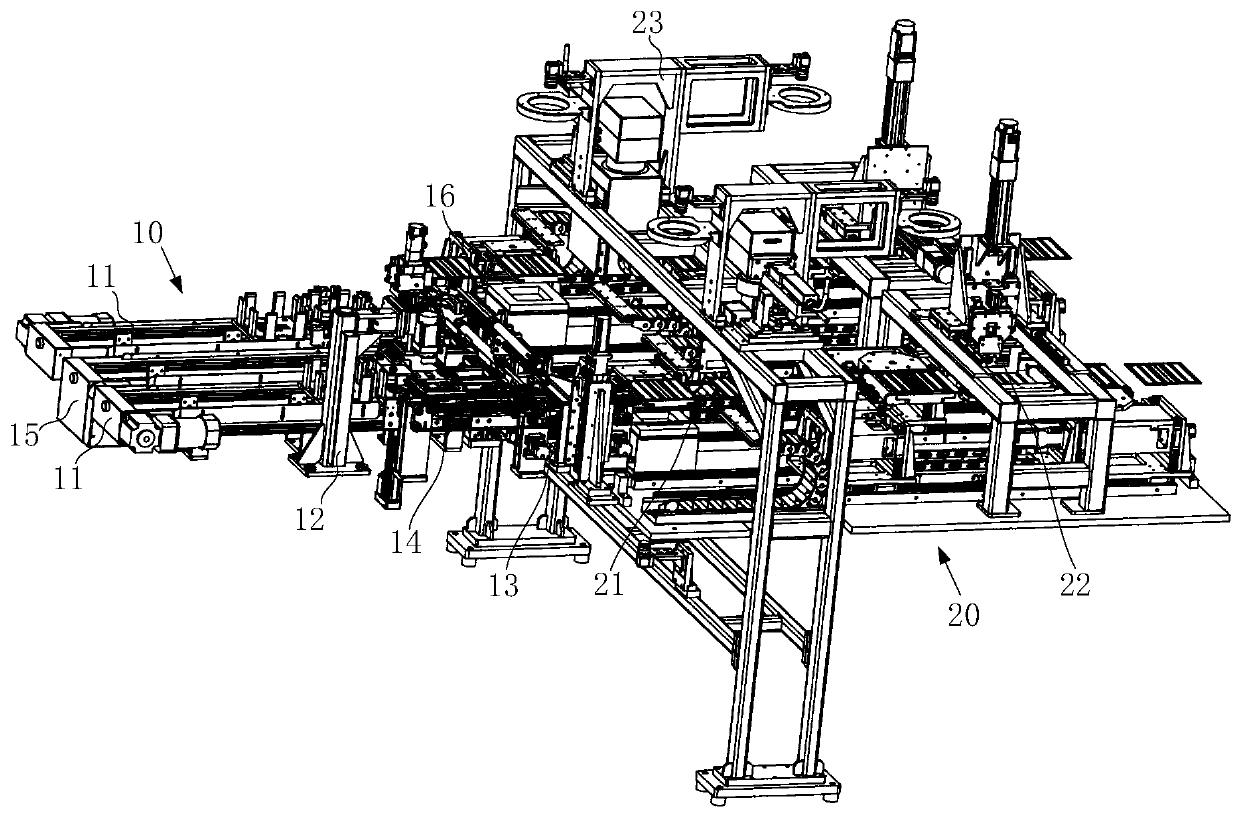

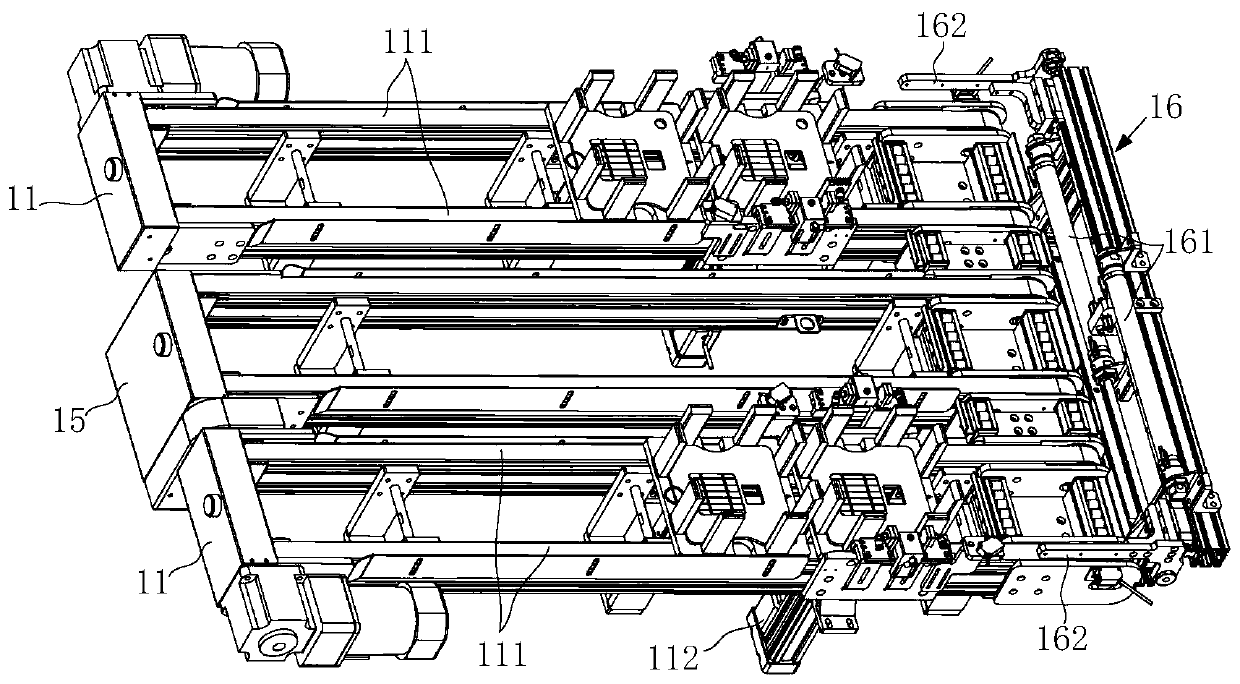

[0059] figure 1 Shown is an optional embodiment of the shingled battery string production equipment 1, figure 1 is a top view floor plan of the device. The shingled battery string production equipment 1 at least includes a battery sheet feeding part 10 , a battery sheet processing part 20 , a breaking sheet conveying part 30 , a regular stacking part 40 and a curing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com