Self-assembled monolayer and perovskite solar cell preparation methods and perovskite solar cell

A technology for self-assembly of single molecules and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as low stability, and achieve the effect of improving performance, optimizing interface, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] To prepare the standard parts of unmodified perovskite solar cells, the preparation steps are as follows:

[0038] 1) Etch ITO, and wash it with detergent solution, deionized water, acetone, and ethanol for 20 minutes, and treat it with ultraviolet ozone for 4 minutes. First, nickel oxide nanoparticles were dissolved in deionized water at a concentration of 20 mg / ml, and ultrasonically treated for 5 minutes before spin coating.

[0039] 2) Then spin-coat the nickel oxide solution onto the treated ITO at a speed of 4000rpm for 30s, and then spin-coat at 130 o Annealed at C for 20 minutes.

[0040] 3) Immediately transfer the device to the glove box, spin-coat the perovskite on the nickel oxide layer by stirring the perovskite solution overnight at 4000rpm for 30s, and then spin-coat the perovskite on the nickel oxide layer at 105 o C for 20 minutes at temperature.

[0041] 4) After waiting for cooling to room temperature, the PCBM solution was spin-coated onto the per...

Embodiment 2

[0044] Preparation of monomolecular layer modified perovskite solar cells: the previous steps are the same as steps 1) and 2) in Example 1, and the subsequent steps are the same as 3) to 5). The difference is that step 2) and step 3) are supplemented with the preparation of a modification layer. The specific steps are as follows:

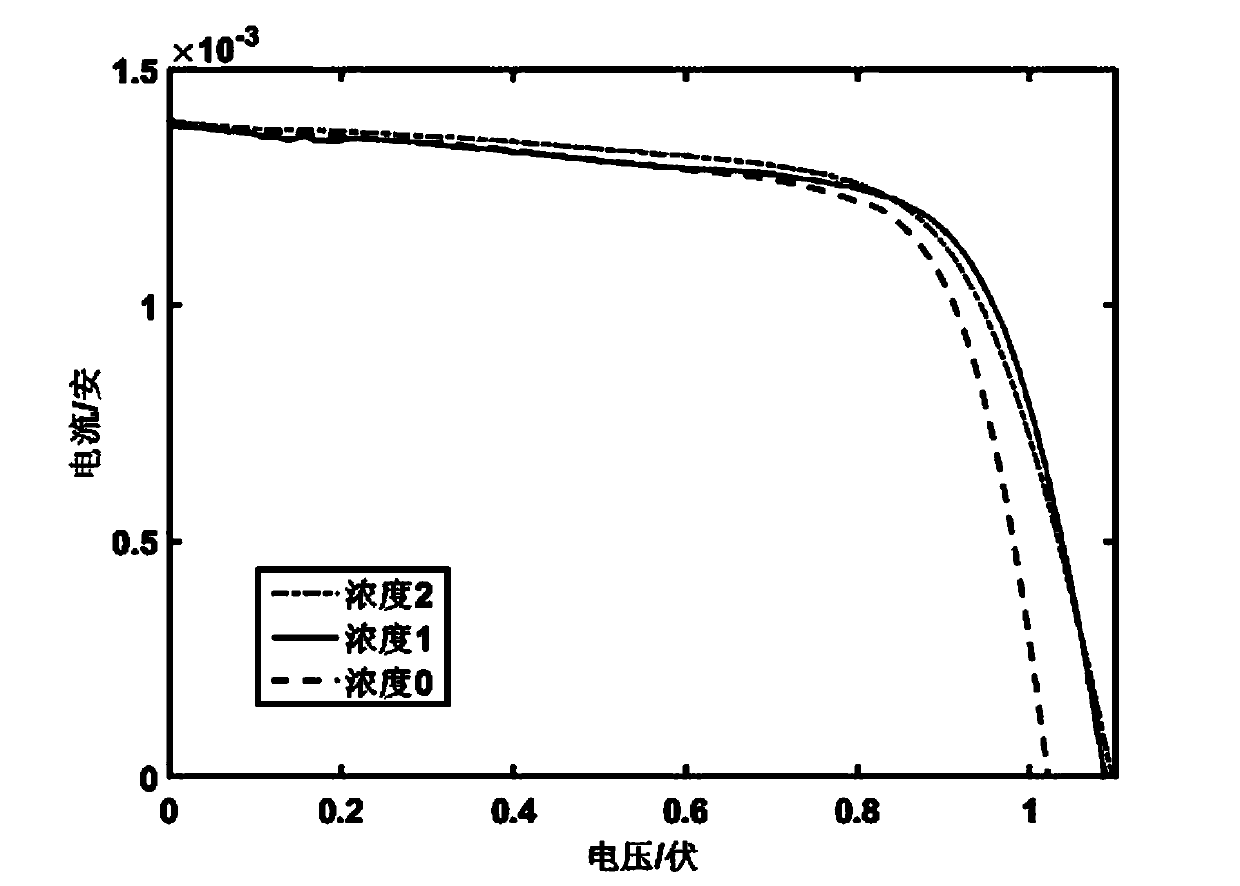

[0045] Dissolve 4-carboxyphenylisothiocyanate in ethanol solution to obtain a 20mg / ml solution, and filter it with a 22um filter head. Then obtain 0.5mg / ml, 1mg / ml, 2mg / ml monomolecular layer solution by diluting, the solution of three kinds of concentrations is spin-coated 30s according to the speed of 2000rpm in turn, then at 70 o C for 5 minutes at temperature. After waiting for cooling, ethanol was used to spin-coat twice at 2000rpm, the spin-coating time was 30s, and then at 70 o C for 5 minutes at temperature.

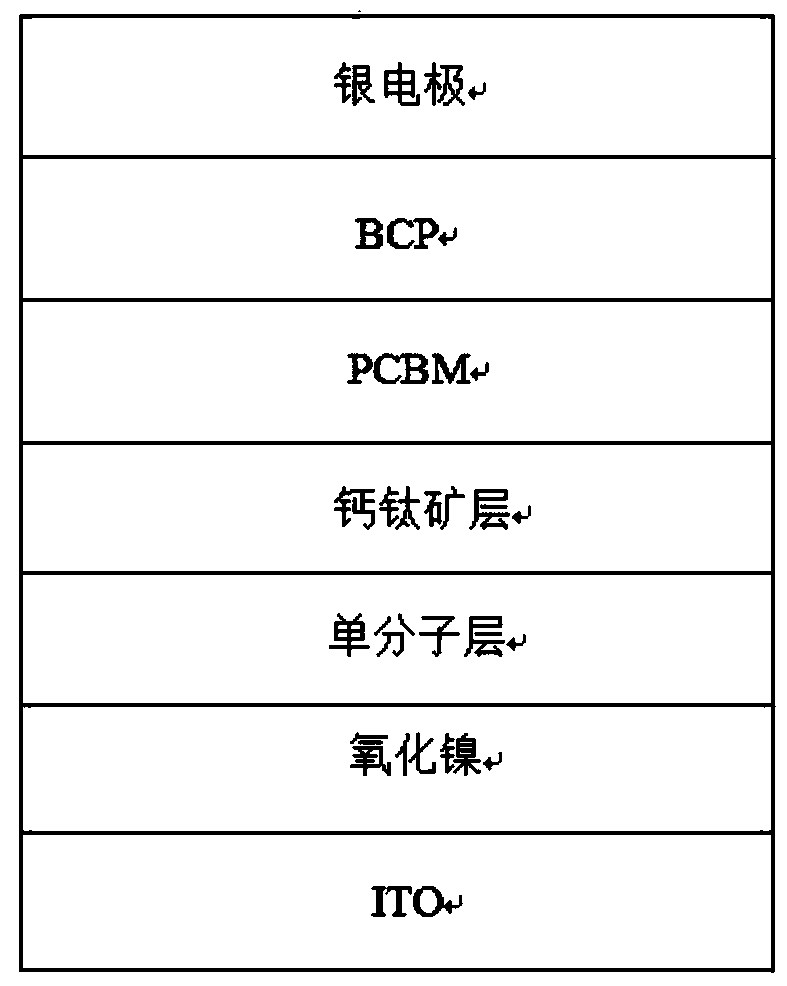

[0046] The battery structure of the present embodiment 2 is as figure 1 As shown, the new structure proposed by the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com