Telescopic crossing-over frame

A spanning and telescopic technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the workload of construction personnel, unstable power output process, and large structural quality, so as to achieve stable and reliable overall structure and stable power output process , Guarantee the effect of the network blocking time requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

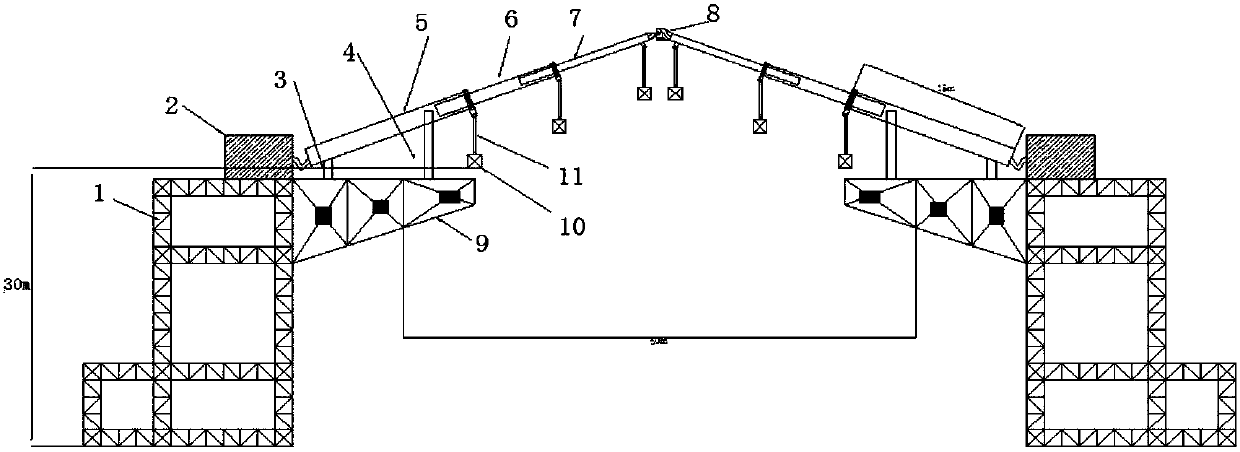

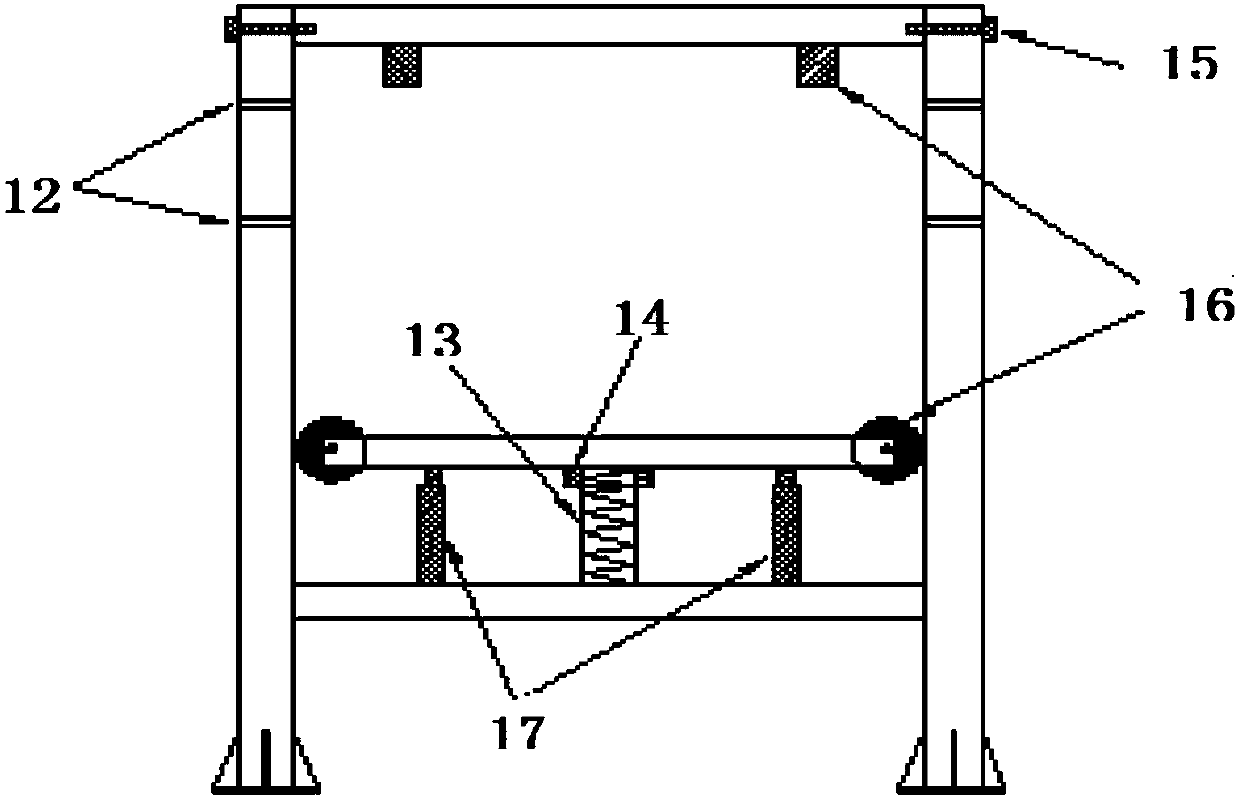

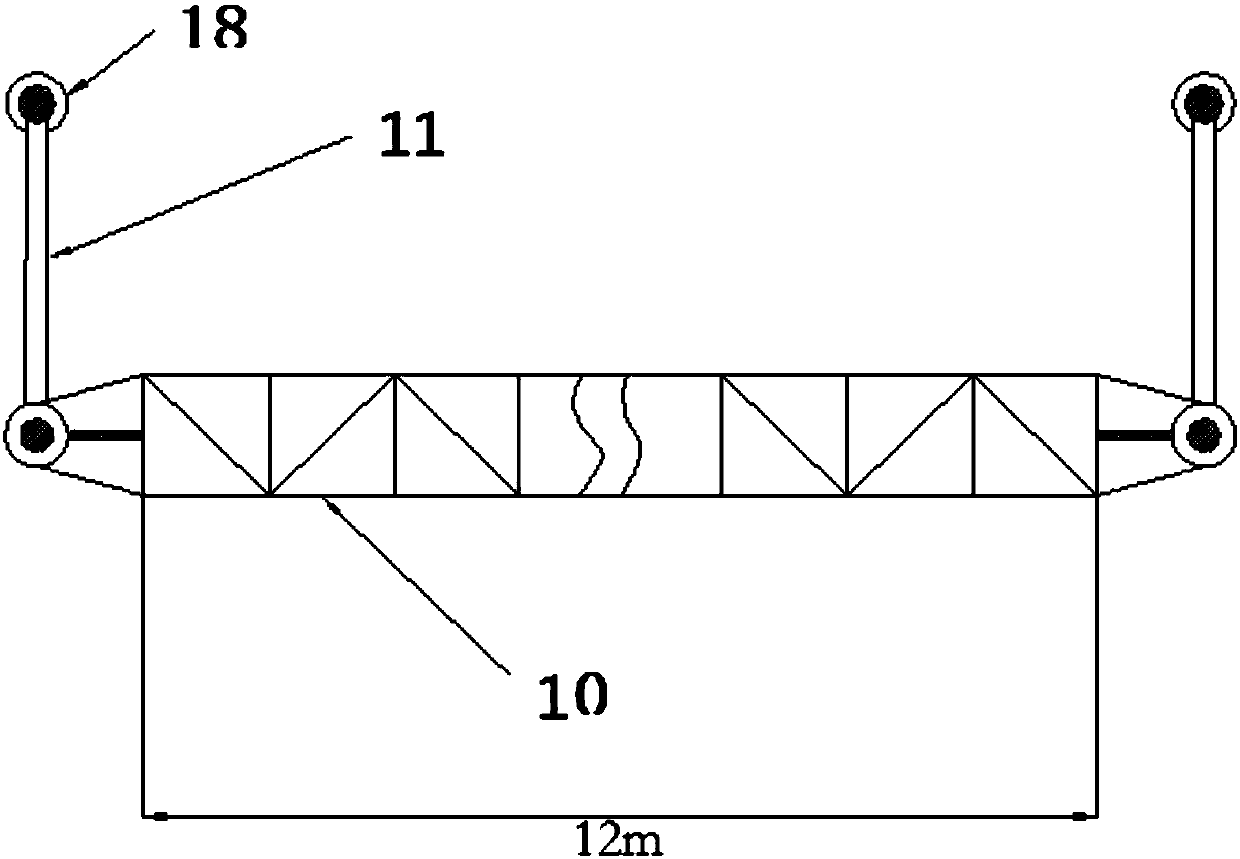

[0021] The overall structure of the telescopic spanning frame provided by the present invention is as follows: figure 1 As shown, during the installation process, the end of the box-shaped telescopic arm of the telescopic span frame connects the hard-sealed net holding pole 10 through the rigid universal joint 11 and the ball hinge 18. During the extension of the telescopic arm, the hard-sealed net The holding pole 10 moves along the spanning direction together with each arm section until it is installed in place. Such as image 3 As shown in the schematic diagram of the sealing net holding rod and the connecting rod, the hard sealing net holding rod 11 is installed on the ends of the inner layer arm joints of the box-type telescopic telescopic boom on both sides through the ball hinge 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com