Spraying and rust preventing device for surface of building material

A technology of surface spraying and building materials, which is applied in the field of building materials, can solve the problems of low spraying efficiency and achieve the effects of improving spraying efficiency, simple and fast unlocking operation, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

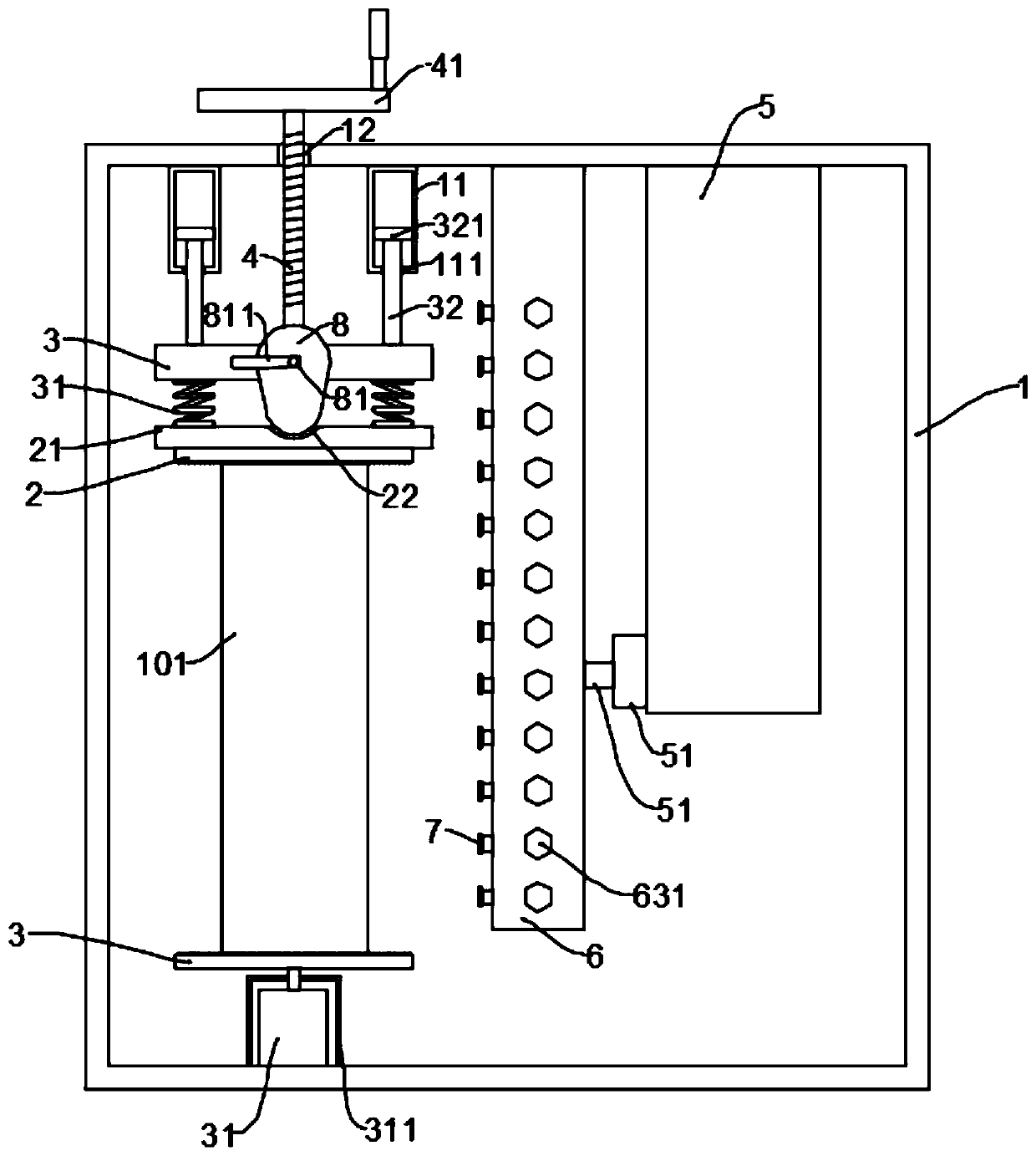

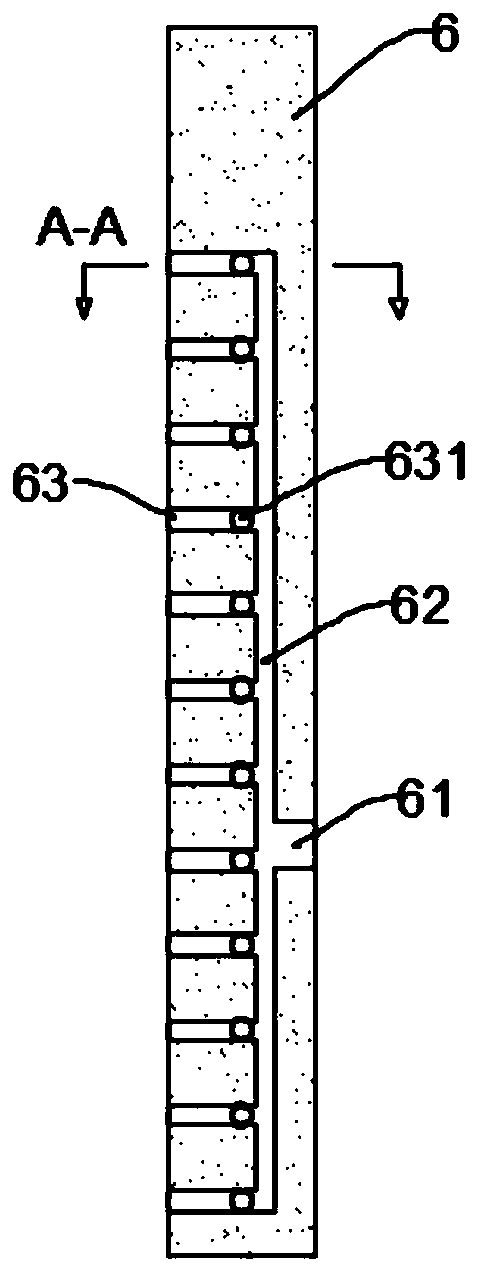

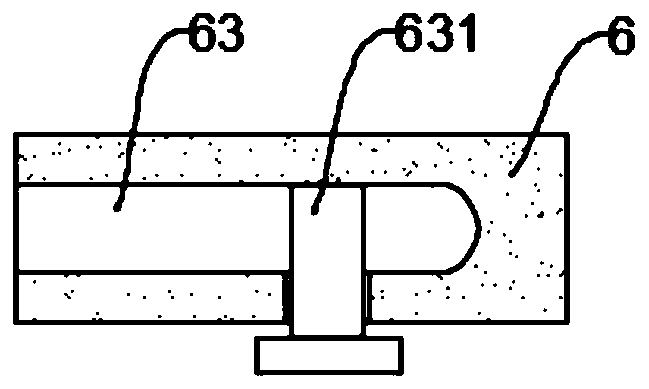

[0023] see Figure 1~3 , in an embodiment of the present invention, a construction material surface spray rust prevention device includes a housing 1, a clamping assembly and a liquid spraying assembly are arranged in the housing 1; the clamping assembly includes an upper platen 2 and a lower Pressing plate 3; the upper pressing plate 2 is rotatably connected to the bottom of the connecting seat 21, a moving plate 4 is arranged above the connecting seat 21, the moving plate 4 is connected to the connecting seat 21 through a connecting piece 41, and the moving plate 4 is slidingly clamped on the housing 1; the top center of the moving plate 4 is rotatably connected with a screw 43, and the other end of the screw 43 protrudes from the housing 1 and is connected with an operating handle 431, and the housing 1 is provided with a screw rod 43 matched threaded holes 12, so that when the screw mandrel 43 rotates, it will drive the moving plate 4 to move downward; the lower pressing p...

Embodiment 2

[0030] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that a recovery pump 9 is also installed on the liquid storage tank 5, the outlet end of the recovery pump 9 communicates with the liquid storage tank 5, and the inlet end of the recovery pump 9 is connected with The liquid return pipe 91, the other end of the liquid return pipe 91 extends to the bottom of the inner cavity of the housing 1, so that the dripping paint can be re-pumped into the liquid storage tank 5 to avoid waste of resources;

[0031] Further, the bottom surface of the inner chamber of the housing 1 is inclined towards the liquid return pipe 91 , which is more conducive to the suction of paint by the liquid return pipe 91 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com