Technology to prevent continuous casting slab narrow side bulging

A process method and continuous casting slab technology, which is applied in the field of slab width adjustment technology, can solve problems such as cracking, narrow-side copper plates detached from the slab shell, and steel breakout, so as to avoid steel breakout accidents, stabilize production and improve slab production. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

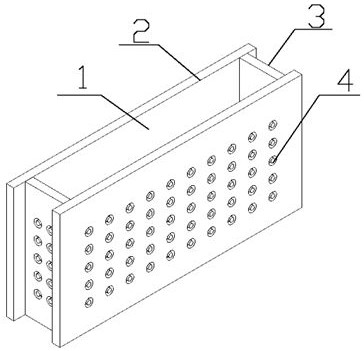

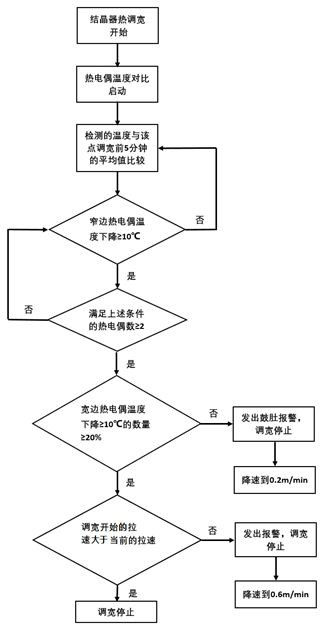

[0033] 1. For a certain steel type, it is planned to carry out thermal width adjustment during pouring, and the width of crystallizer 1 is reduced from 1500mm to 1400mm;

[0034] 2. When the pouring speed is 1.3m / min, start to adjust the width;

[0035] 3. Before the width adjustment starts, the detected temperatures of the three thermocouples 4 in a row of the narrow-side copper plate 3 on the east side of the crystallizer 1 are 250, 225, and 190°C respectively;

[0036] 4. At the beginning of width adjustment, the detection temperature of thermocouple 4 remains unchanged, and when the width adjustment is about to end, the detection temperatures of the above three thermocouples 4 drop to 223, 195, and 176°C respectively;

[0037] 5. At this time, the detection temperature of the thermocouple 4 on the wide copper plate 2 does not change, and the pulling speed does not change;

[0038] 6. The system sends out a bellows alarm and automatically reduces the speed to 0.2m / min;

...

Embodiment 2

[0042] 1. For a certain steel type, it is planned to carry out thermal width adjustment during pouring, and the width of crystallizer 1 is increased from 1200mm to 1350mm;

[0043] 2. When the pouring speed is 1.1m / min, start to adjust the width;

[0044] 3. Before the width adjustment starts, the detected temperatures of the three thermocouples 4 in a row of the narrow-side copper plate 3 on the west side of the crystallizer 1 are 223, 210, and 185°C respectively;

[0045] 4. At the beginning of width adjustment, the detection temperatures of the above three thermocouples 4 drop to 205, 188, and 160°C respectively;

[0046] 5. At this time, the detection temperature of the thermocouple 4 on the wide copper plate 2 does not change, and the pulling speed does not change;

[0047] 6. The system sends out a bellows alarm and automatically reduces the speed to 0.2m / min;

[0048] 7. The operator inspected and found that the actual reverse taper on the west side was a negative num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com