Composite sheet separator and aluminum steel separating device

A composite sheet and separator technology, applied in the field of aluminum-steel separation, can solve the problems of cracking at the connection between the aluminum sheet and the steel sheet, damage to the composite sheet, etc., and achieve the effects of quick cutting and separation, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

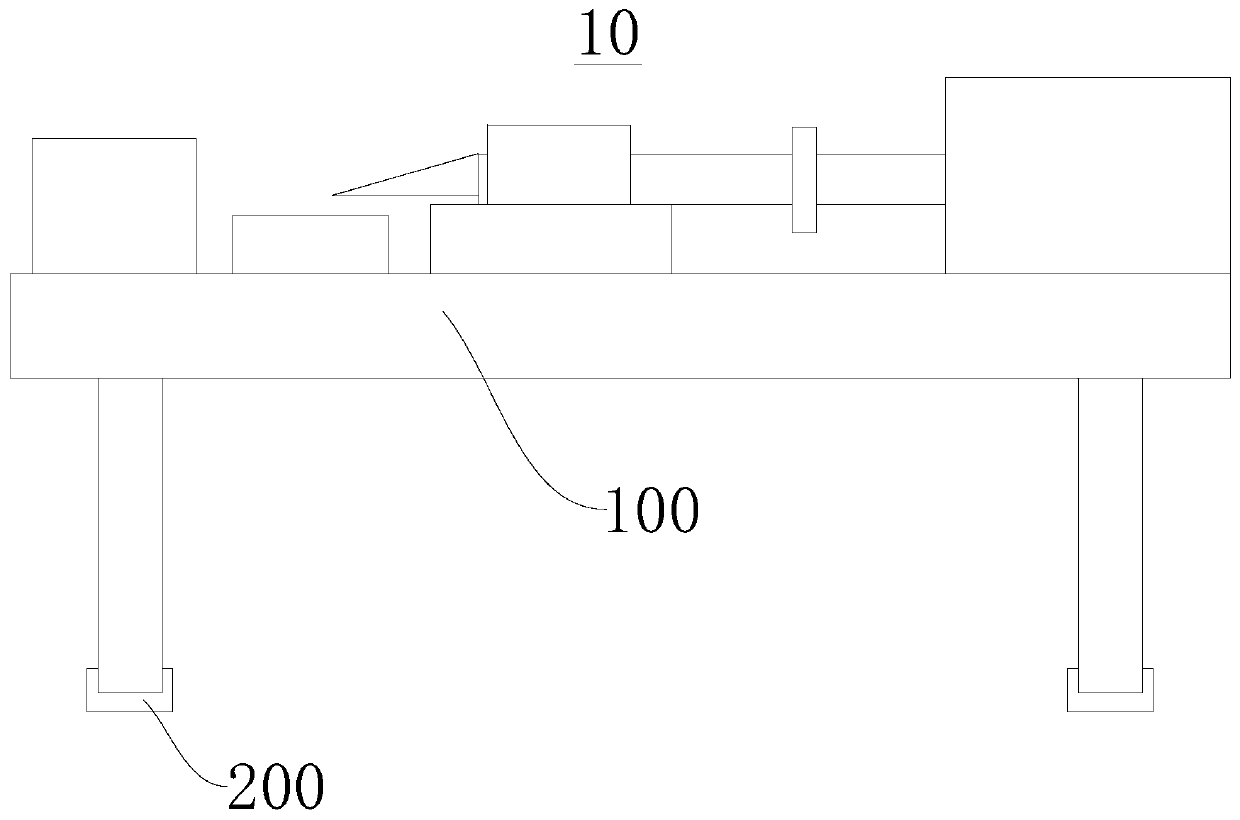

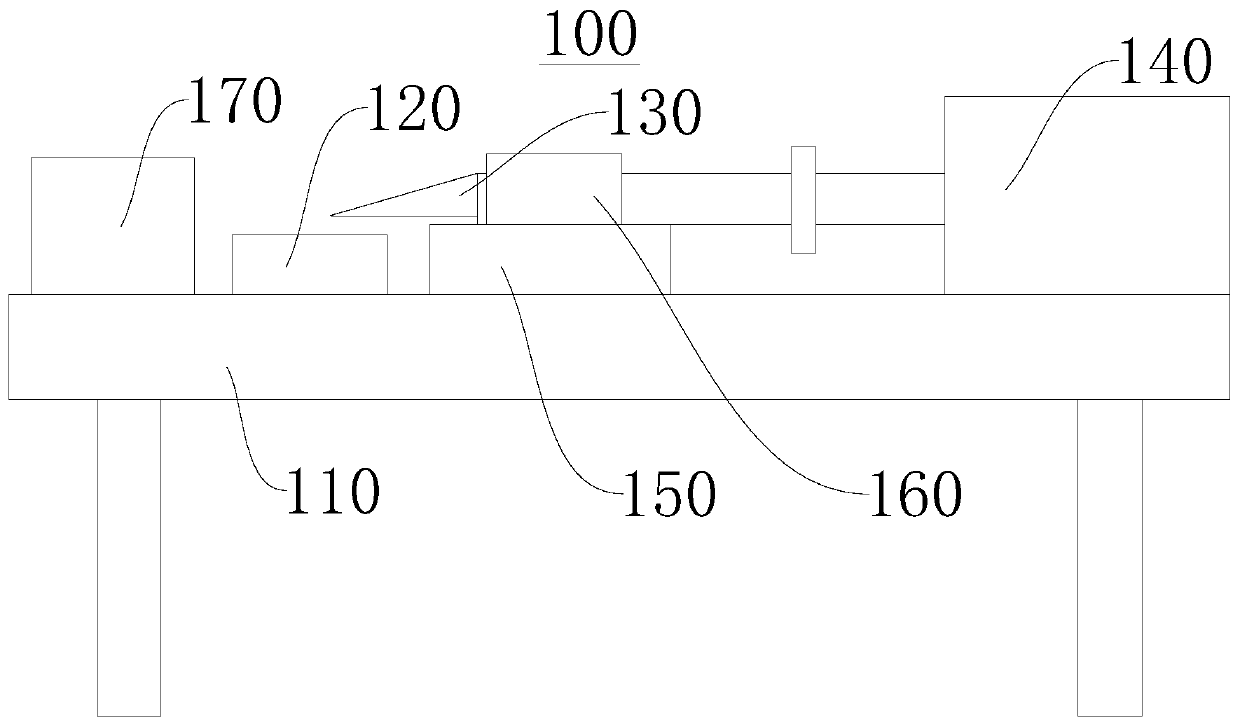

[0035] Please refer to figure 1 , the embodiment of the present invention provides an aluminum-steel separating device 10 for cutting and separating aluminum-steel composite sheets into aluminum plates and steel plates. The utility model has the advantages of simple structure, quick cutting and separation of aluminum-steel composite sheets, high separation efficiency, reduced cost, improved economic benefit, strong practicability and high cost performance. The aluminum-steel separating device 10 includes a composite sheet separator 100 and a shock-absorbing pad 200 . The shock-absorbing gasket 200 is fixedly installed on the bottom of the composite sheet separator 100. The composite sheet separator 100 is used for cutting aluminum-steel composite sheets, and the shock-absorbing gasket 200 is used for shock-absorbing the composite sheet separator 100 to reduce the risk of composite sheet separation. The noise produced when the machine 100 is working.

[0036] Please refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com