Internal and external gas barrier device of screw conveyor

A screw conveyor and gas barrier technology, applied in packaging and other directions, can solve problems such as aggravated air leakage, air leakage, and explosion of material pipe 11, and achieve the effect of strengthening heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with the drawings, and the attached drawings are mainly simplified schematic diagrams, only schematically illustrating the basic structure of the present invention, so only components related to the present invention are indicated in these drawings , and the displayed components are not drawn according to the number, shape, size ratio, etc. of the implementation, and the actual implementation specifications and sizes are actually a selective design, and the layout of the components may be more complicated.

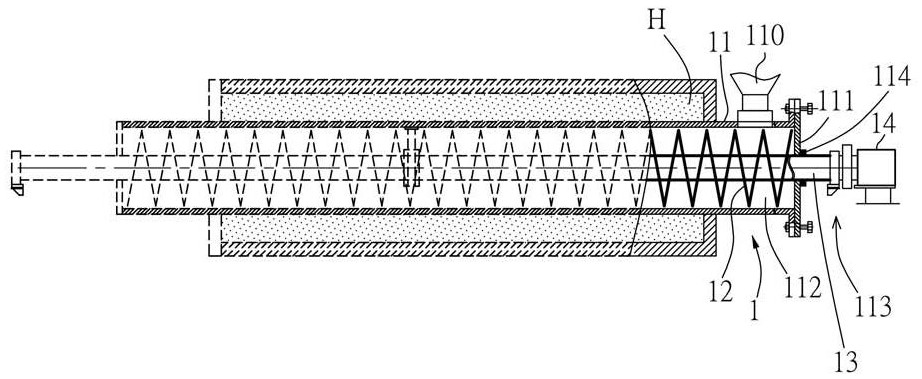

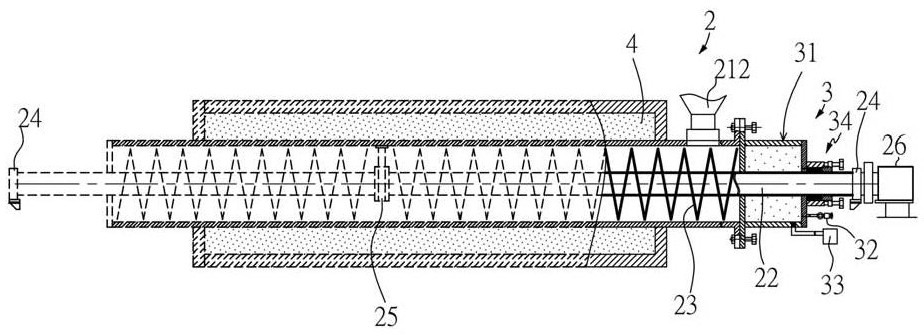

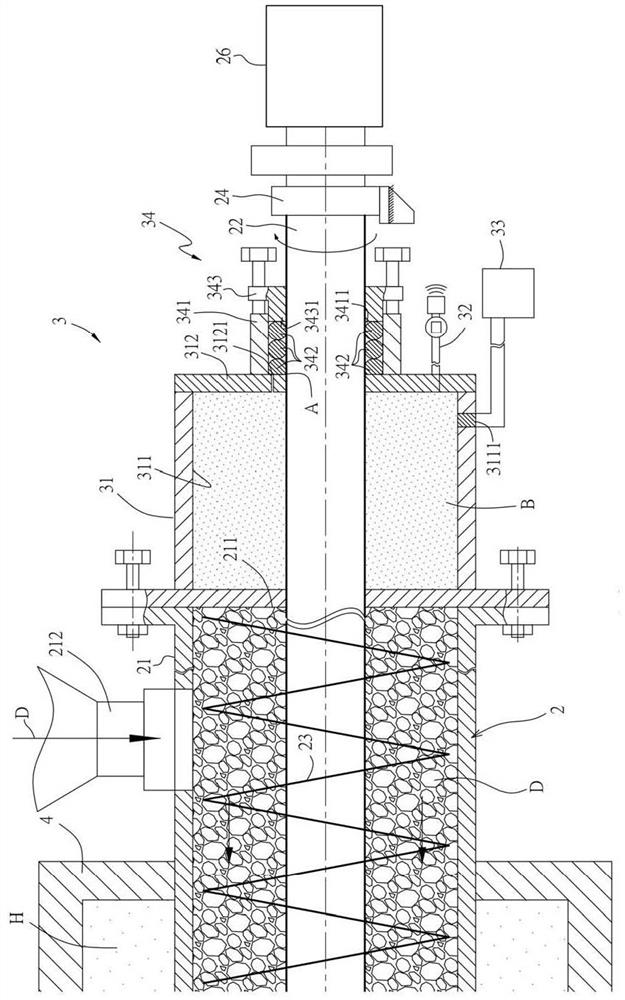

[0020] First, please refer to figure 2 and image 3 shown. In the internal and external gas barrier device 3 of the screw conveyor 2 of the spiral thermal cracking reaction furnace of the present embodiment, the screw conveyor 2 includes a material tube 21 with an end plate 211, and a rotating shaft 22 that runs through the central axis of the material tube 21 , a helical blade 23 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com