Horizontal reference device by adopting low-melting-point alloy and leveling method thereof

A level reference, low-melting point metal technology, applied in the direction of measuring devices, artificial horizontal planes, active optical measuring devices, etc., can solve the problems of high storage requirements, low safety, high requirements for testing equipment and personnel, and achieve convenient operation and security Horizontal accuracy, the effect of avoiding the leakage of metal solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

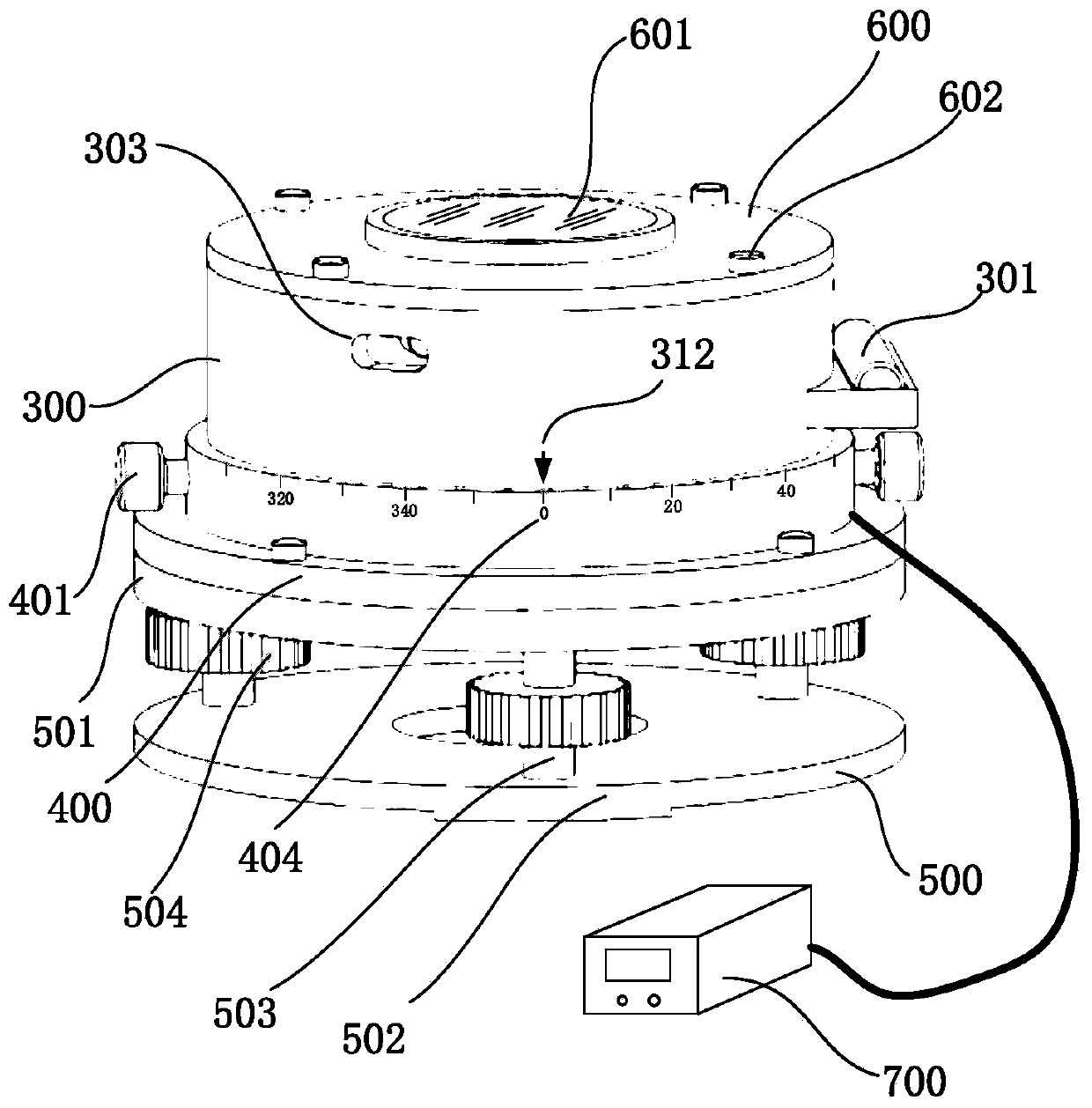

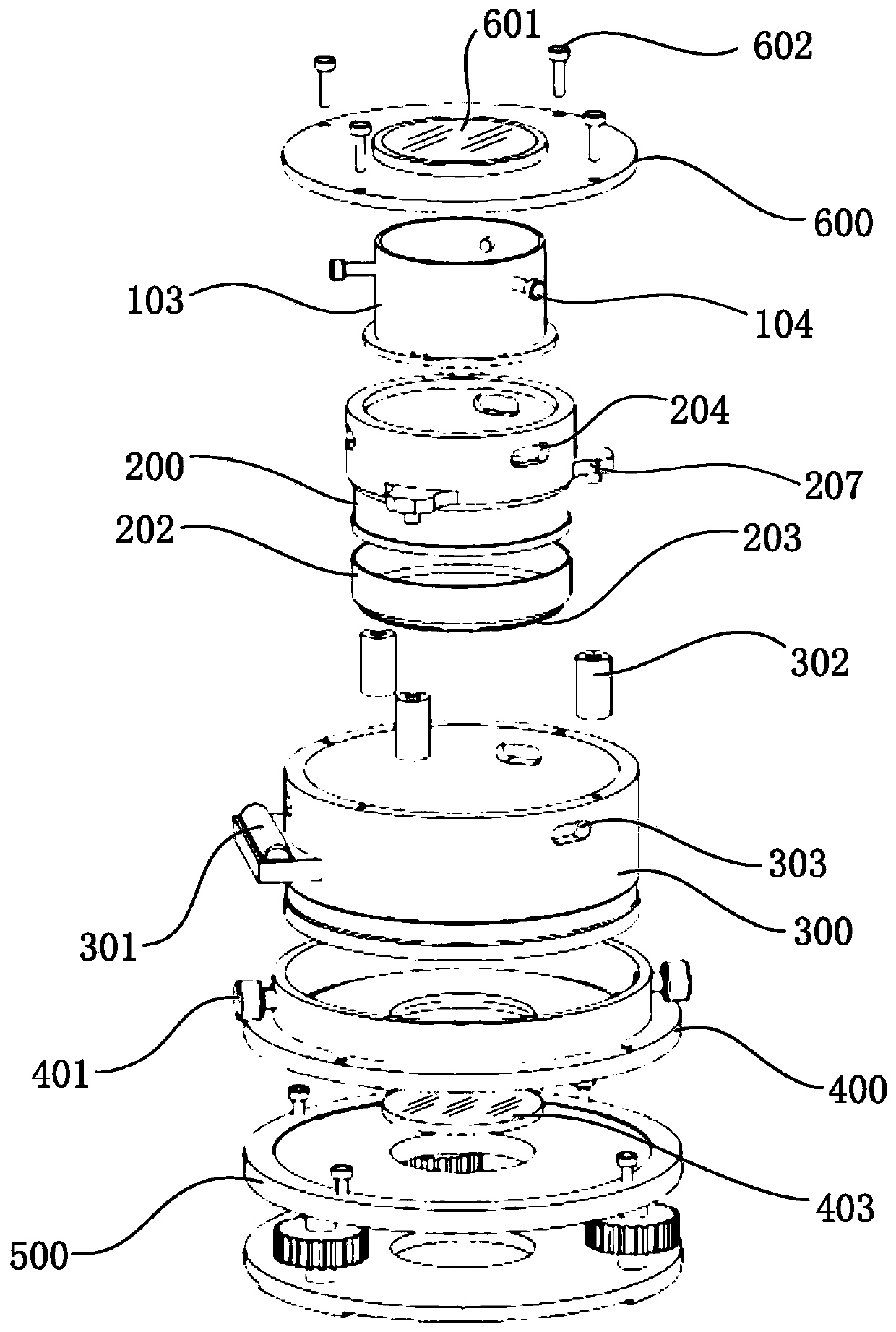

[0057] Such as figure 1 , figure 2 , image 3 As shown, the horizontal reference device using low melting point alloy provided in this embodiment includes a horizontal reference platform 100, a low melting point metal alloy container 200, a rotary table 300, a rotary seat 400, a tripod leveling mechanism 500, and a dust cover 600 and temperature control system 700. The horizontal reference table 100, the low-melting-point metal alloy container 200, the rotating table 300, and the rotating seat 400 are arranged sequentially from inside to outside; the upper end.

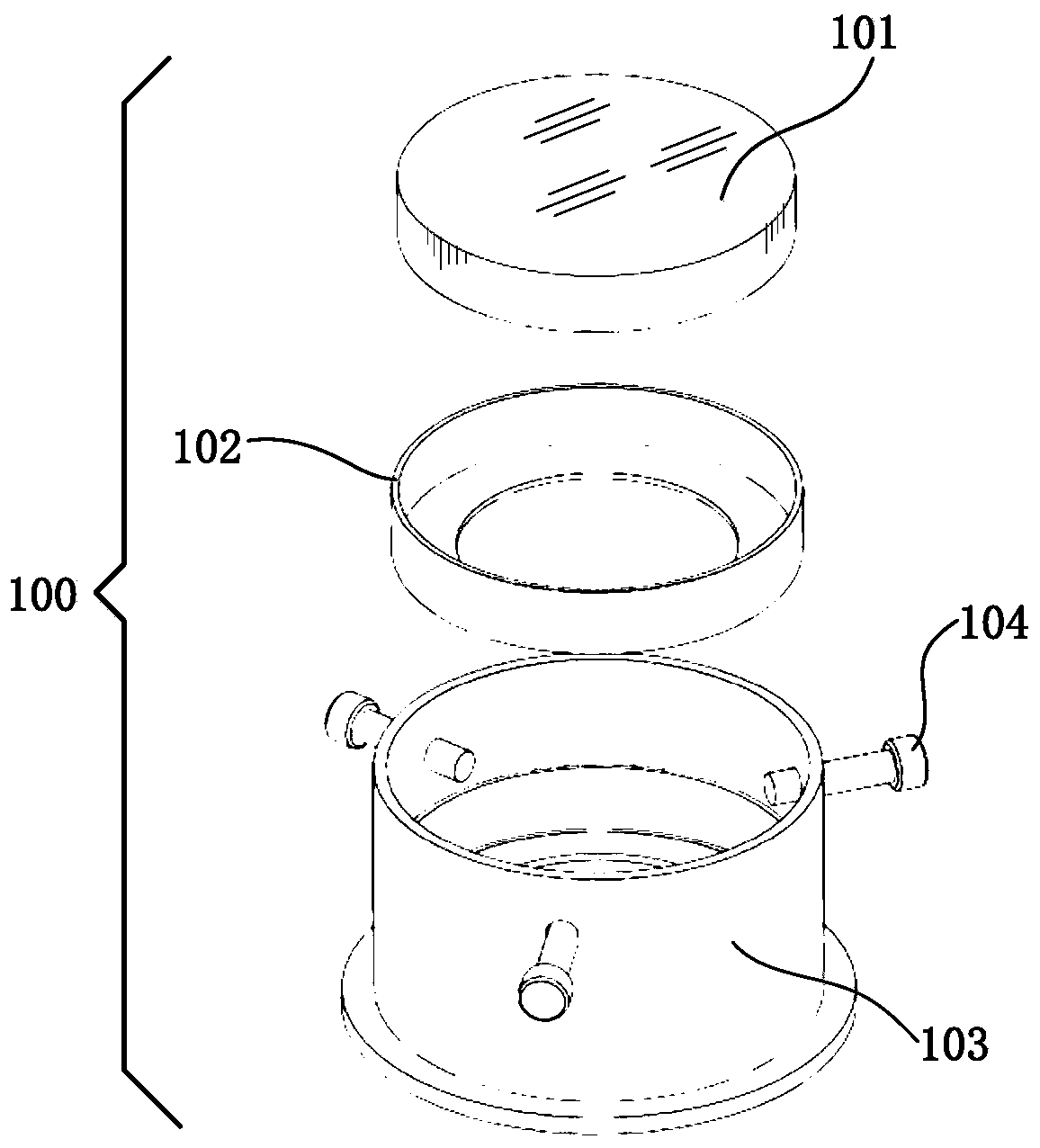

[0058] Such as image 3 As shown, the horizontal reference platform 100 includes a leveling base 103 and a plane reflector 101; the leveling base 103 is a hollow cylindrical structure with an open top and a closed bottom, and a light hole is provided at the center of the closed end of the bottom; the plane re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com