Method for improving effective coverage of sound field of ultrasonic probe, and ultrasonic detection wedge block

An ultrasonic probe, ultrasonic testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. , the detection process is cumbersome and other problems, to achieve the effect of increasing the effective coverage, improving the consistency, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0040] The present invention proposes a method for improving the effective coverage of the ultrasonic probe sound field, including:

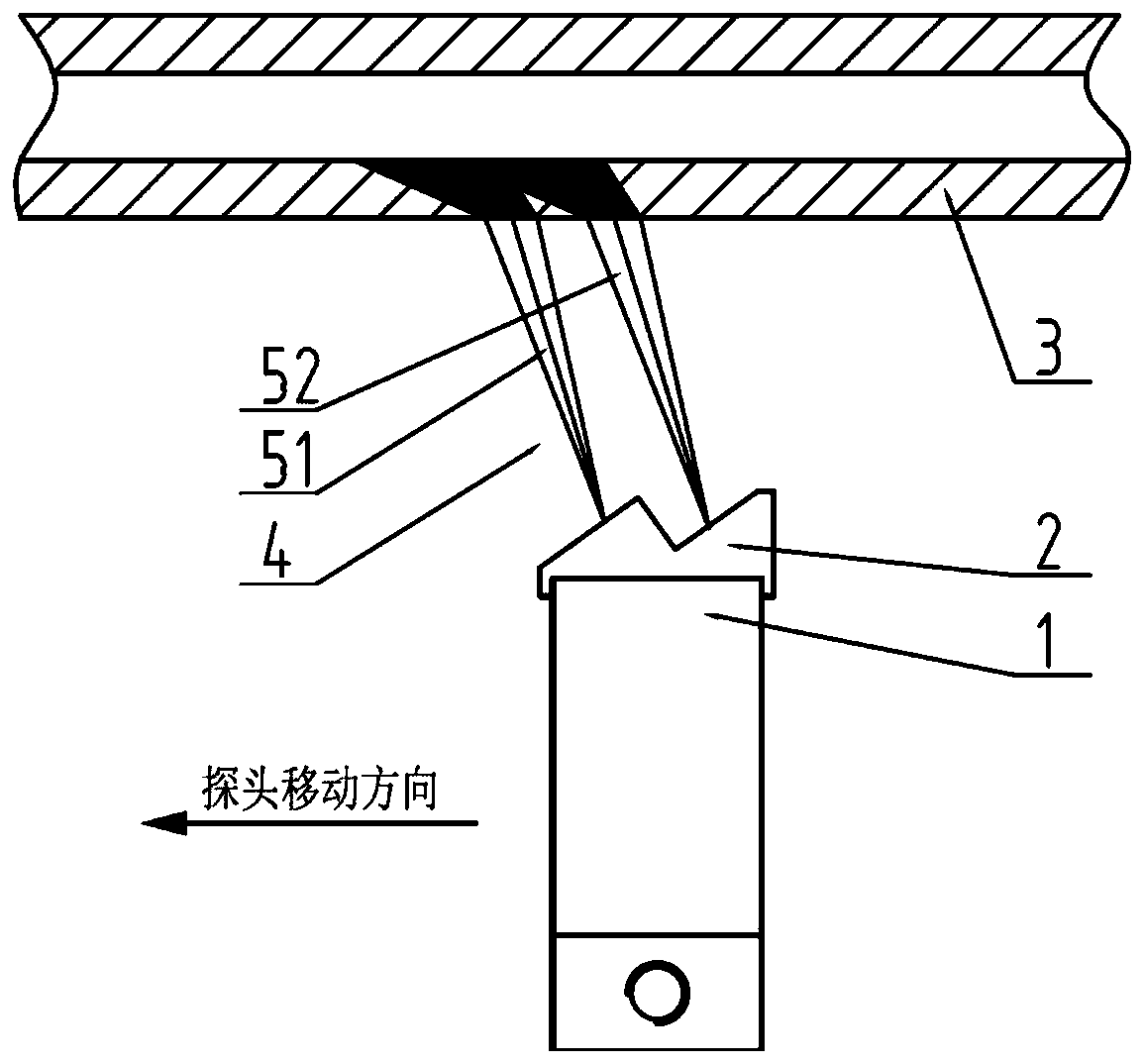

[0041] Step S1, determining the parameters of the ultrasonic testing wedge at least according to the structural size of the ultrasonic probe and the material of the coupling agent, and the ultrasonic testing wedge is attached to the ultrasonic probe;

[0042] Step S2, using the ultrasonic detection wedge to divide the ultrasonic waves emitted by the ultrasonic probe into sound beams to form multiple sound beams, and simultaneously detect the workpiece;

[0043] Step S3, the ultrasonic probe and the ultrasonic detection wedge move laterally relative to the workpiece, and the ultrasonic probe receives echo signals to detect defects inside the workpiece;

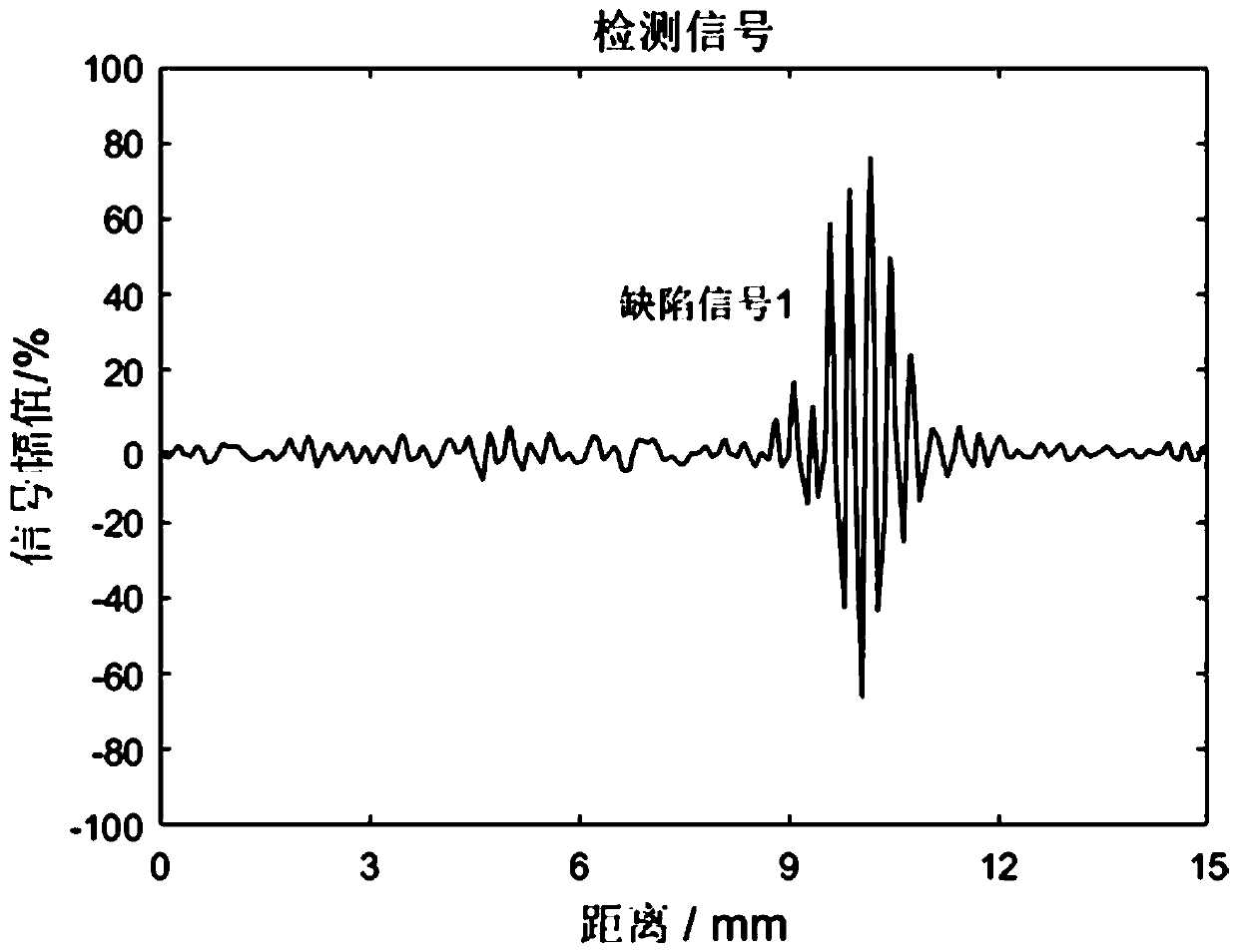

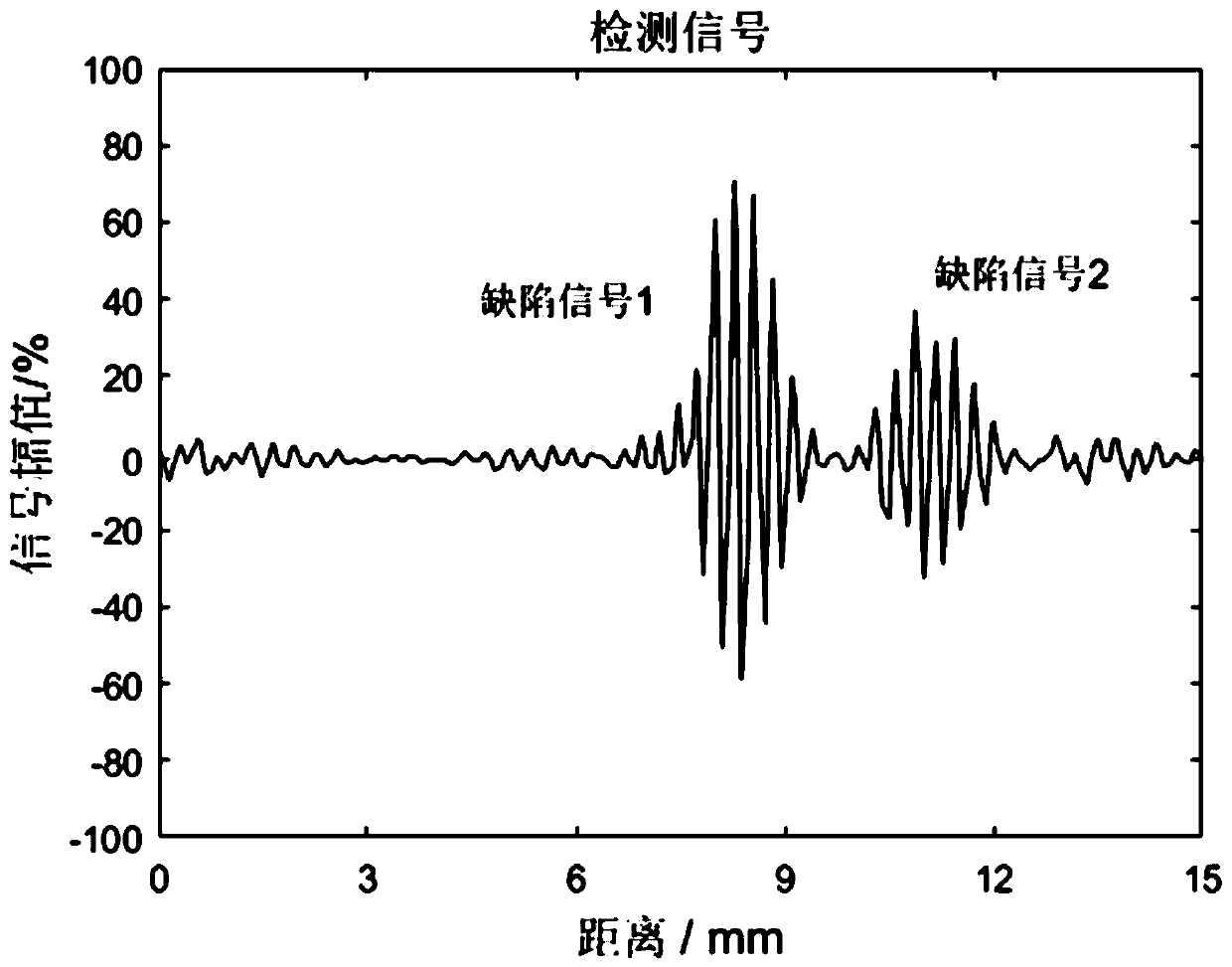

[0044] In some embodiments of the present invention, the multiple acoustic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com