Rolling bearing radial clearance intelligent design method based on body

A radial clearance and rolling bearing technology, applied in the field of intelligent design of rolling bearing radial clearance based on the body, can solve the problems of radial clearance groups and clearance values that are difficult to intelligentize, and achieve portability and hierarchy The effect of clear relationship and guaranteed scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

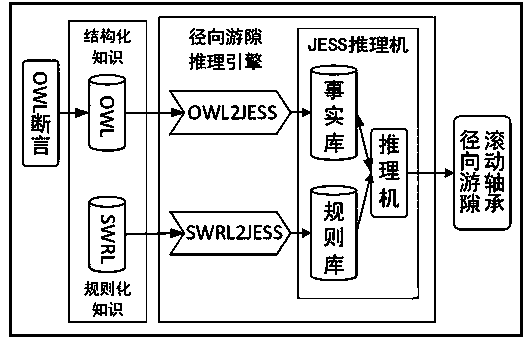

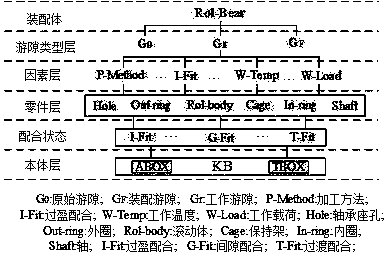

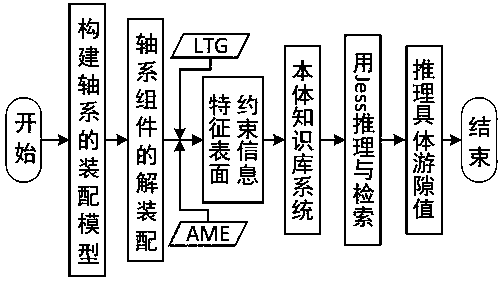

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in further detail below with the example of a certain mining machine of a certain model.

[0035] A mining machine is driven by a DC motor, and its journal is Y=190mm, which is processed by turning. Supported by a pair of short cylindrical roller bearings 32238, the standard clearance of the bearings is , During operation, the temperature of the bearing reaches 85°C, try to determine the proper radial working clearance of the bearing. Known data: radial load on the bearing , the coefficient of linear expansion of the bearing material is ;Bearing inner diameter , outer diameter , the inner raceway diameter of the bearing , Raceway diameter of bearing outer ring , the roller diameter of the bearing , roller length , the number of rollers .

[0036] Step 1. Consult the relevant knowledge in the field of radial clearance of rolling bearings and build a mathematical model. According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com