Method for simulating and calculating Brinell hardness of titanium sponge

A technology of Brinell hardness and simulation calculation, which is applied in calculation, computer material science, and special data processing applications, etc. It can solve the problems of poor simulation calculation accuracy, deviation of actual hardness value, correlation between unanalyzed impurities and Brinell hardness, etc. achieve accurate predictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

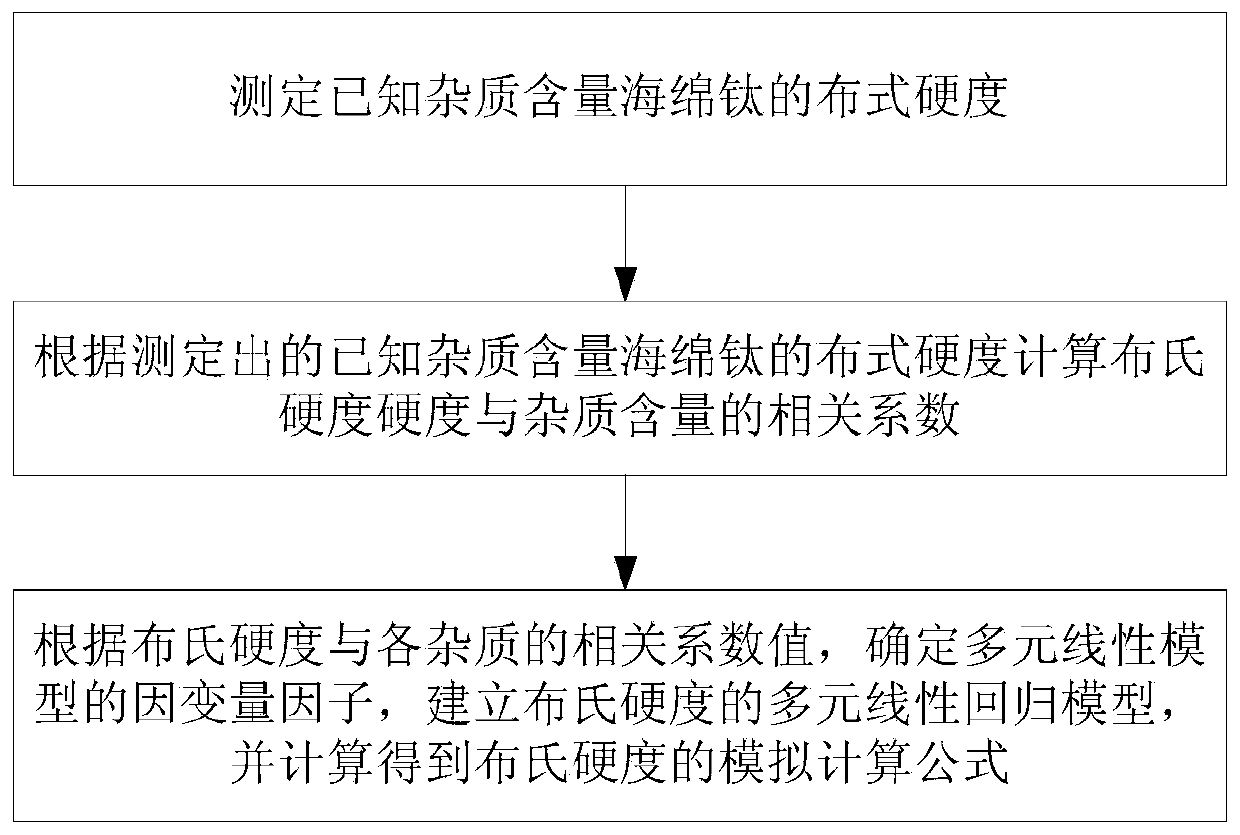

[0044] The embodiment of the present invention simulates and calculates the method for the Brinell hardness of titanium sponge, comprising the following steps:

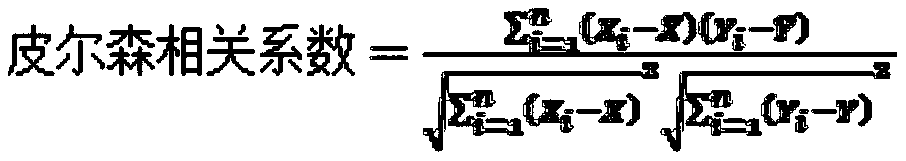

[0045] (1) Use the corrcoef function of Matlab software to calculate the Pearson correlation coefficient of each impurity element and Brinell hardness (BH), and the Pearson correlation coefficient of each impurity of gained and Brinell hardness is as shown in table 1:

[0046] Table 1 The Pearson correlation coefficient between the Brinell hardness of sponge titanium and each impurity element

[0047]

[0048] (2) Based on the highly correlated O, N, Ni, C, Al, and Fe impurities, establish a multiple linear regression model to establish a multiple linear regression model for the simulation calculation of the sponge titanium Brinell hardness:

[0049] HB=m 0 +m 1 ×Fe%+m 2 ×C%+m 3 ×N%+m 4 ×O%+m 5 ×Ni%+m 6 × Al

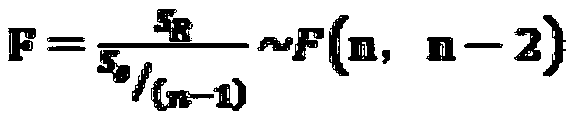

[0050] (3) Use the Regress function of Mintab software to calculate the simulation calculation formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com