High-simulation plant manufacturing method and system based on BIM technology and application to digital modeling of garden landscapes

A technology for simulating plants and production methods, which is applied in 3D modeling, image data processing, instruments, etc., and can solve problems such as inability to integrate, unrealistic plant components, and inability to meet design requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described in conjunction with the following examples.

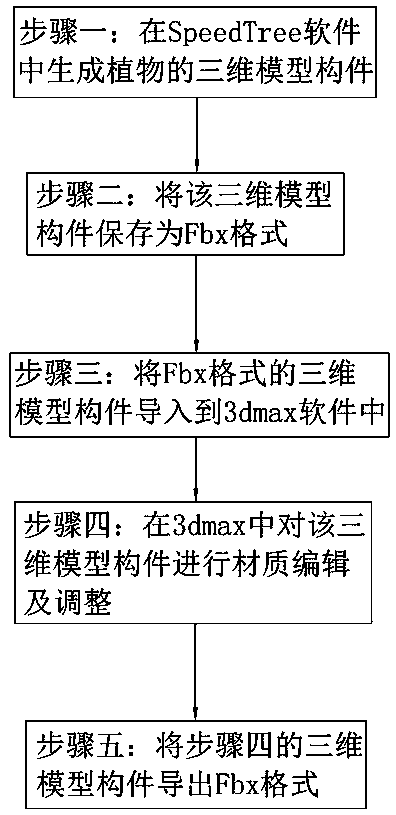

[0037] The method for making high-simulation plants based on BIM technology in this embodiment includes the following steps:

[0038] Step 1: generate the three-dimensional model member of plant in SpeedTree software;

[0039] Step 2: saving the 3D model component as Fbx format;

[0040] Step 3: Import the 3D model components in Fbx format into 3dmax software;

[0041] Step 4: Perform material editing, tree shape and color adjustment on the 3D model component in 3dmax;

[0042] Step 5: Export the 3D model components in Step 4 to Fbx format.

[0043] Preferably, said step 1 includes the following sub-steps:

[0044] Sub-step A: Open the SpeedTree software, select File-New, create a new file, the operation of the viewport is: middle-click to pan, left-click to rotate, and right-click to call up the menu;

[0045] Sub-step B: Use SpeedTree's node-based editor to add nodes, and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com