Chain for vacuum conveyor

A conveyor and vacuum technology, applied in conveyors, transportation and packaging, etc., can solve the problems of insufficient adsorption force, small adsorption area, and difficult application, so as to reduce pressure drop, improve durability, and prevent pressure drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

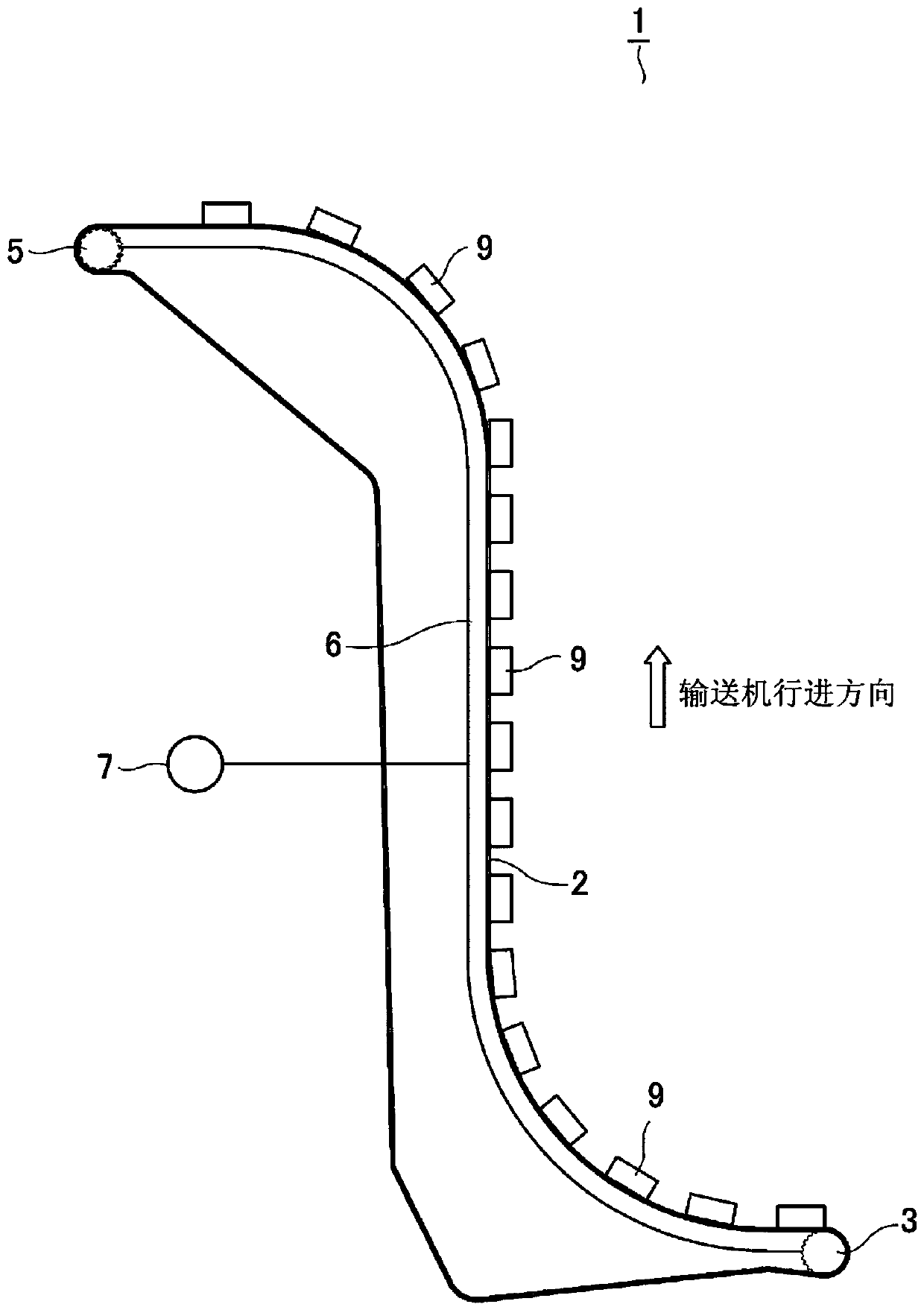

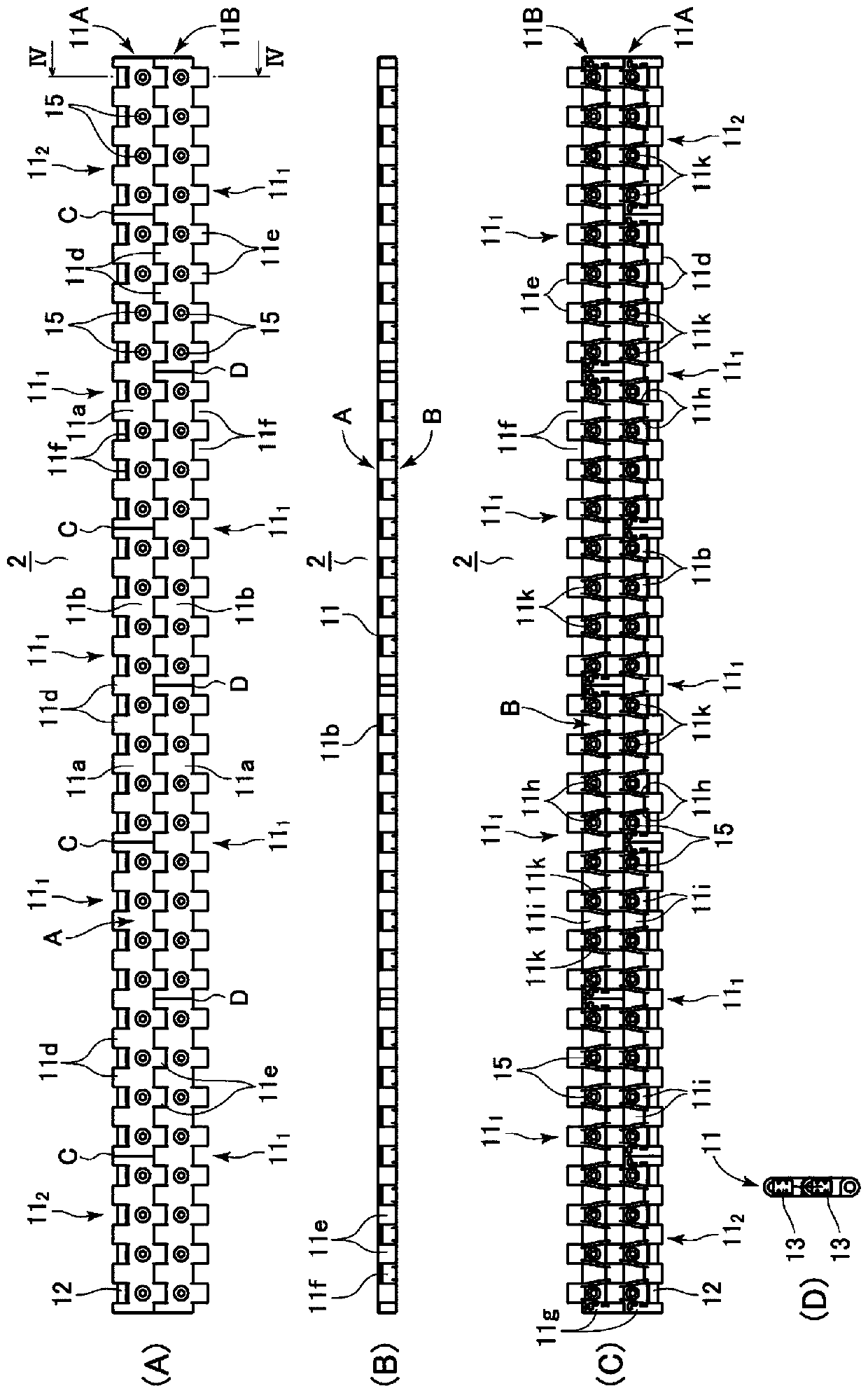

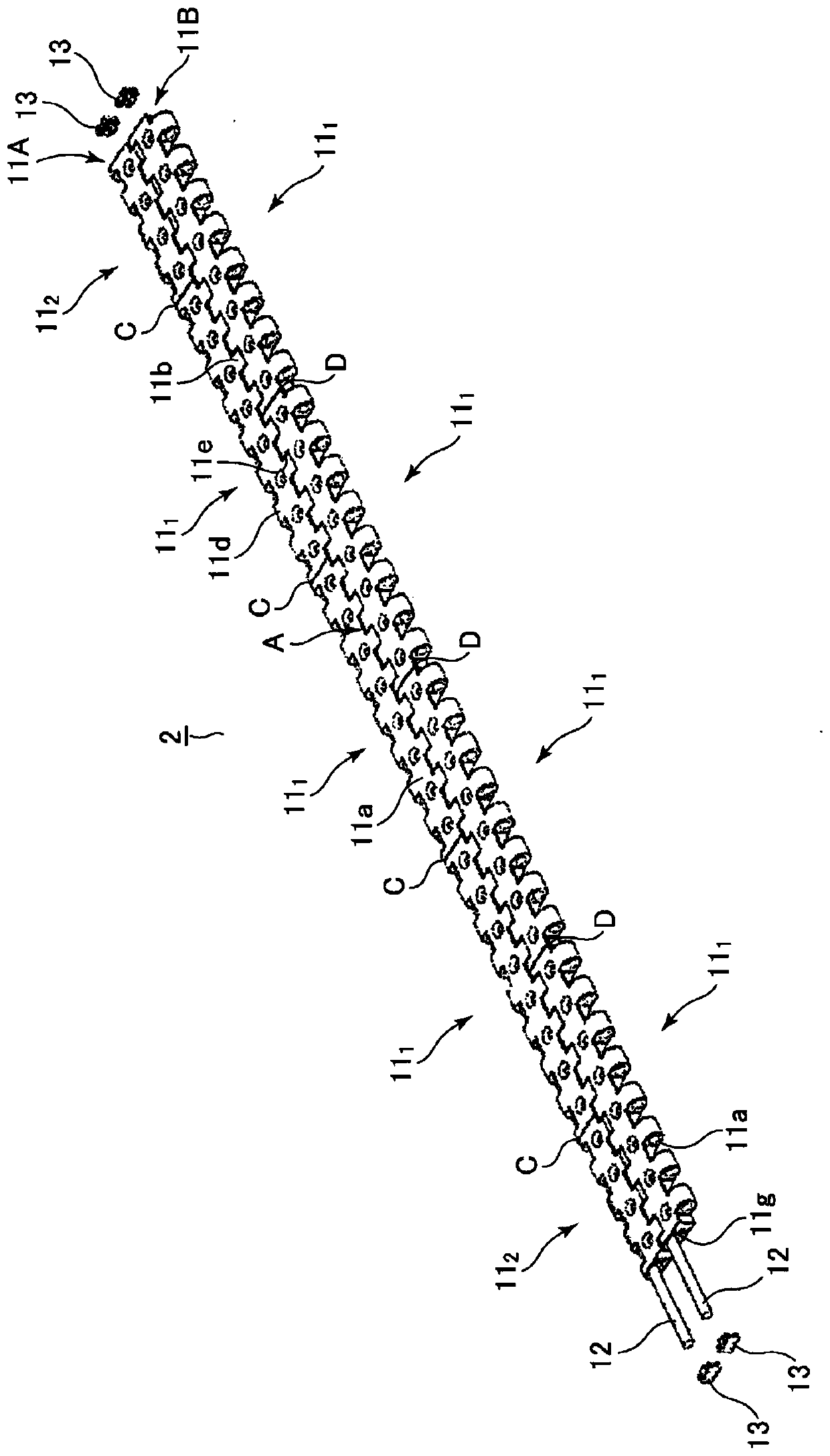

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Such as figure 1 As shown, in the vacuum conveyor 1 to which the present invention can be applied, an endless chain 2 is guided by a moving guide and wound between sprockets 3 and 5 . In the chain 2 , a plurality of links having a flat mounting surface are flexibly connected, driven by rotation of at least one of the sprockets 3 and 5 , and moved while being guided by a moving guide. Suction chambers (suction units) 6 . A suction device (negative pressure device) 7 ... such as a blower fan communicates with the suction chamber 6 , and the suction chamber 6 is brought into a predetermined negative pressure (low pressure lower than atmospheric pressure) state by the suction device 7 . Each link of the chain 2 is respectively formed with suction holes through which the negative pressure from the above-mentioned suction chamber 6 acts on the object to be conveyed 9 such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com