Heating device and heating method

A technology of heating device and heating method, applied in the direction of combustion method, lighting and heating equipment, burner safety device, etc., to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

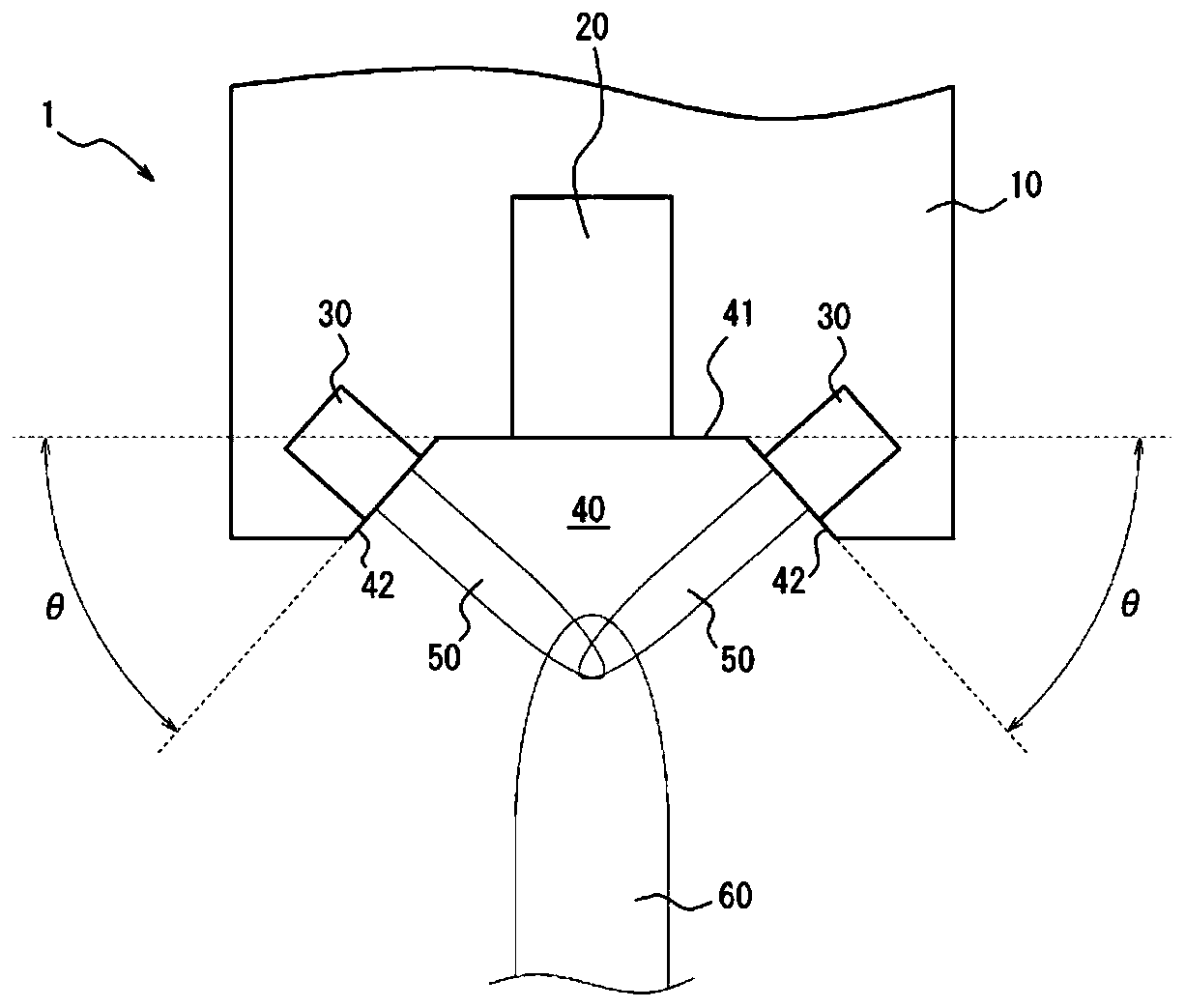

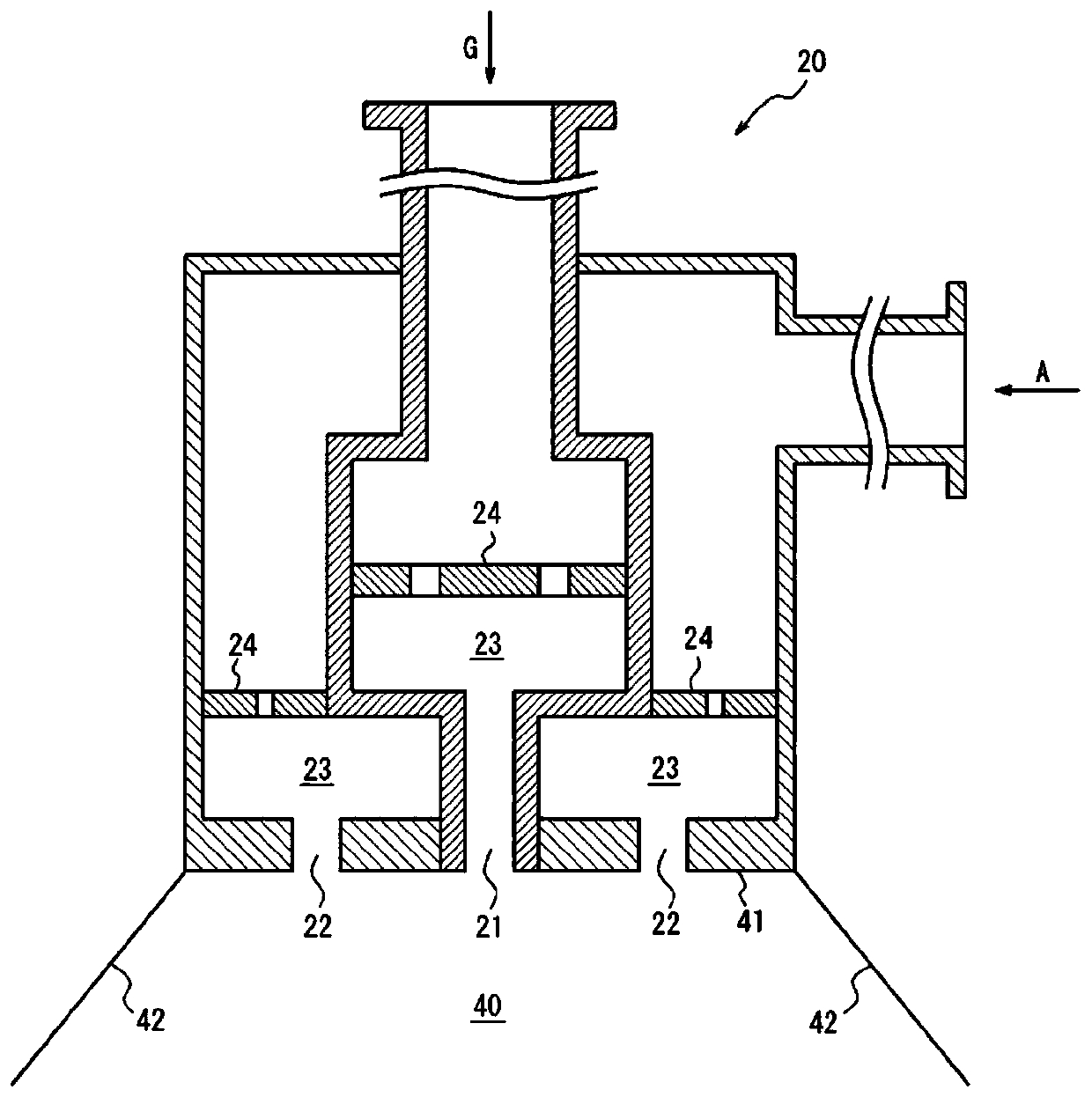

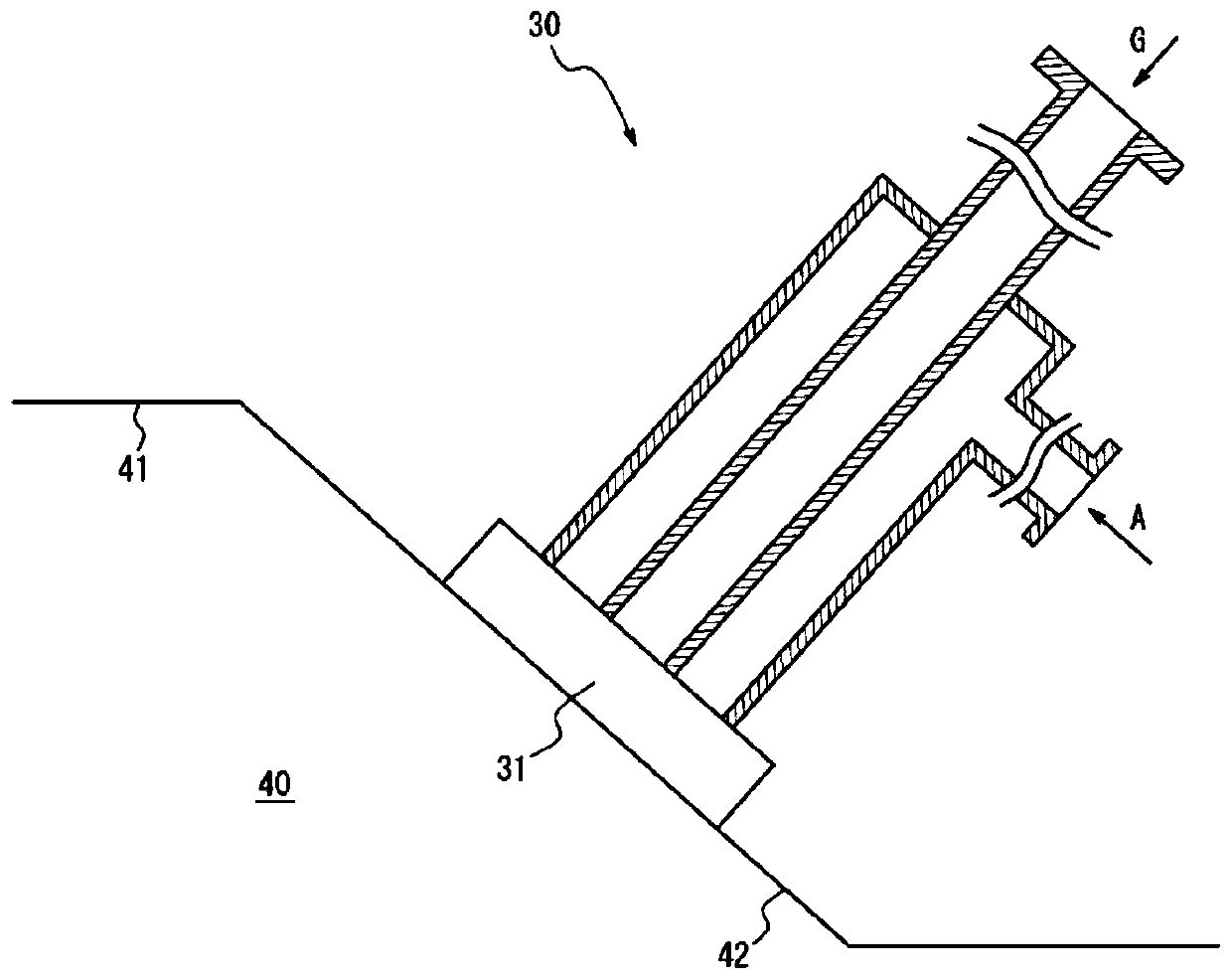

[0077] (Example 1) Figure 1 ~ Figure 3 Burner of construction shown

[0078] In above-mentioned embodiment and comparative example, with figure 1 , 8 The width of the burner in the direction perpendicular to the section shown by etc. is set to 1m. In Table 1, the size of the nozzle and the cross-sectional area of the discharge part are shown. In addition, Table 1 shows the ratio of the flow rate of the fuel gas in the main burner unit to the flow rate of the fuel gas in the pilot burner unit (fuel gas flow rate ratio) in Comparative Example 2 and Example 1 together.

[0079] In Comparative Example 1, a Figure 8 The cross-sectional shape shown is a slit-shaped nozzle with a nozzle width of 10 mm and a length of 1 m. In Comparative Example 2, the one of Patent Document 1, in which 60 sets are arranged linearly between 1 m in the width direction of the burner, was used. figure 1 Nozzle as documented. Since the burner described in Patent Document 1 includes two fuel ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com