Electrode net stretching device for conductive concrete plate

A technology of conductive concrete slabs and tensioning devices, applied in auxiliary forming equipment, ceramic forming machines, manufacturing tools, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

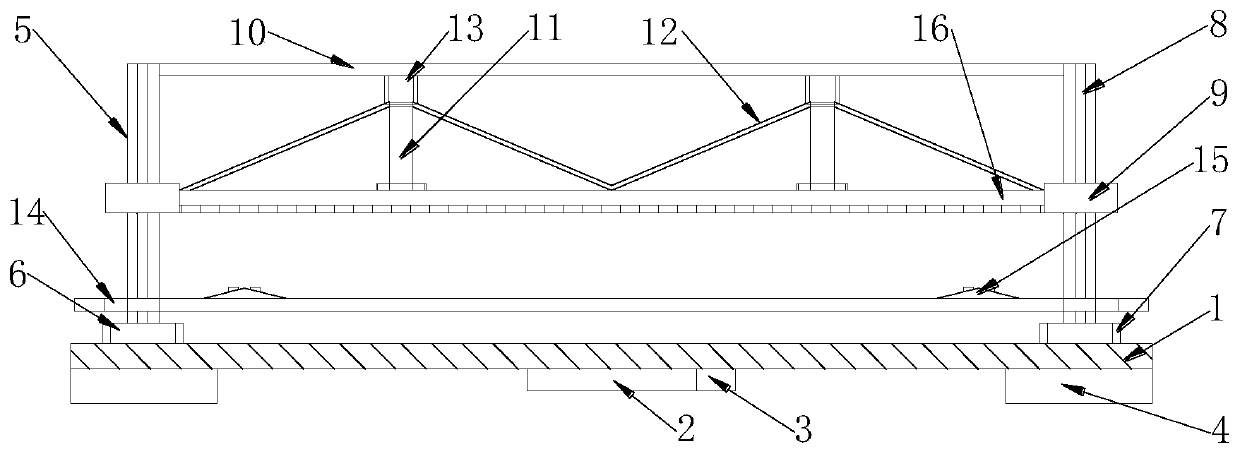

[0011] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: It relates to an electrode net tensioning device for conductive concrete slabs, which includes a base 1, a controller 2, a power supply 3, a shock absorber 4, a support frame 5, and a first straight line Guide rail 6, first slider 7, second linear guide rail 8, second slider 9, fixed rod 10, push rod 11, diagonal brace bracket 12, air pump 13, down-press telescopic plate 14, manipulator 15, up-press telescopic Plate 16; the lower end of the outer wall around the base 1 is equipped with a shock absorber 4, and the middle part of the outer wall of the lower end of the base 1 is equipped with a controller 2, which is used to receive data and control the entire device. There is a power supply 3, and the power supply 3 is used to supply power to the equipment. The first linear guide rail 6 is installed on the left and right sides of the upper outer wall of the base 1, and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com