Method for finely sorting and reusing road milling asphalt waste materials

A kind of asphalt waste, fine separation technology, applied in the field of recycled asphalt, can solve the problems of technical difficulty in recycling, inability to guarantee the use effect of asphalt, and affect the blending rate of RAP, etc., to achieve the reduction of material costs, significant economic benefits, and ease the tension between supply and demand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for finely sorting and reusing road milling asphalt waste, specifically comprising the following steps:

[0031] S1: Use a cold milling machine to plan serious cracks, ruts, potholes, and loose asphalt pavement, and collect and screen the asphalt waste produced by milling;

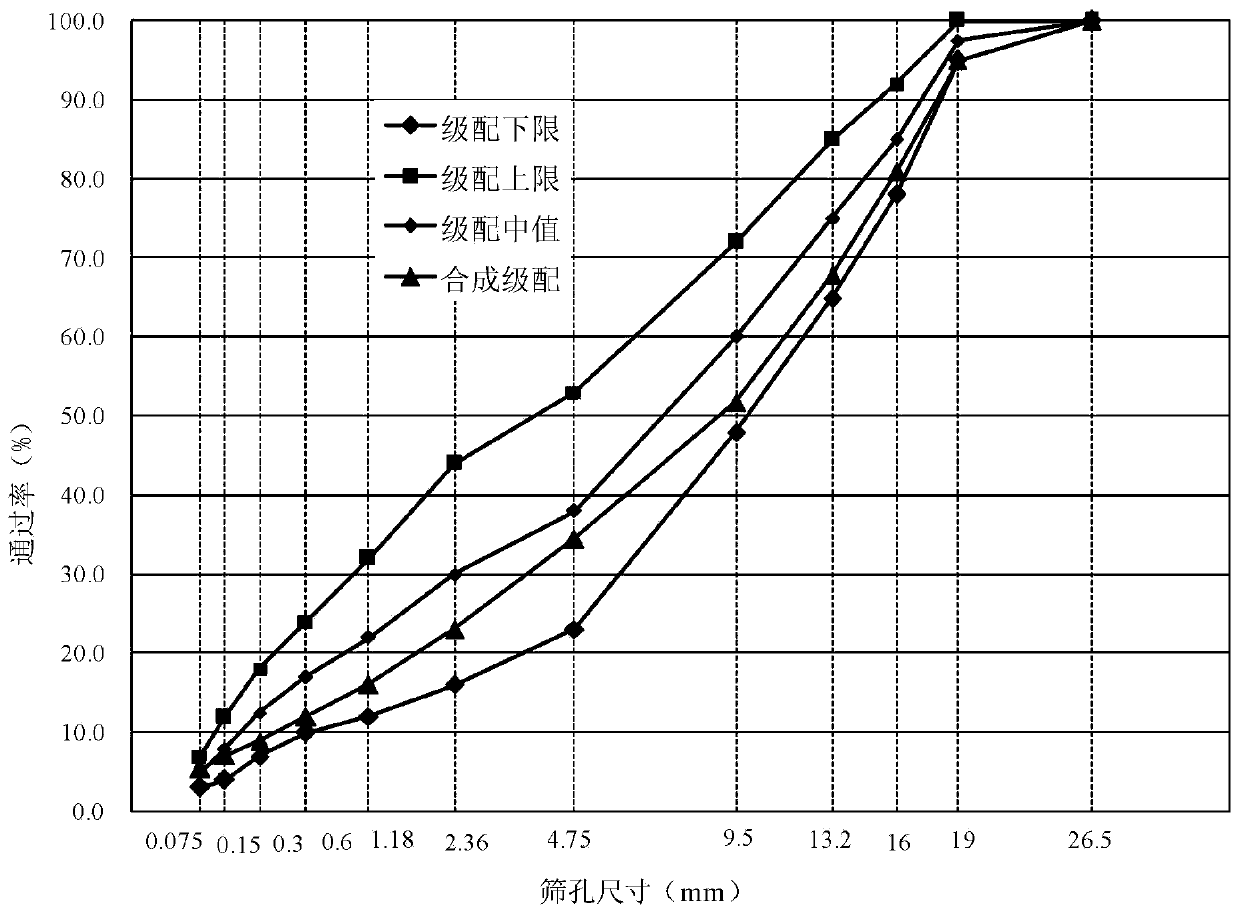

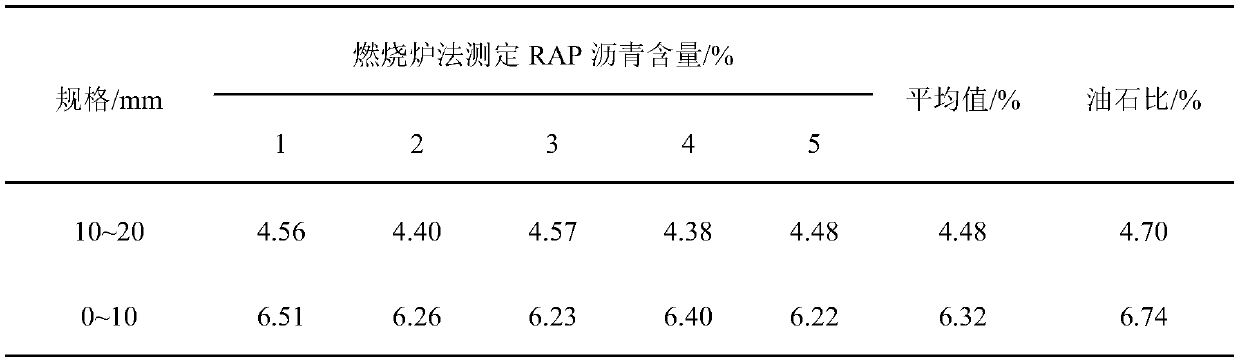

[0032] S2: Use a 11mm sieve to divide asphalt waste into coarse asphalt 10-20mm and fine asphalt 0-10mm, and test the combustion and performance of the two grades of asphalt waste, and also detect the physical indicators in the asphalt waste;

[0033] S3: mix the detected asphalt waste with the currently prepared AC-20 asphalt, and properly adjust the ratio of each grade of material so that the final synthetic gradation is close to the GAC-20 synthetic gradation, that is, a new synthetic asphalt is obtained;

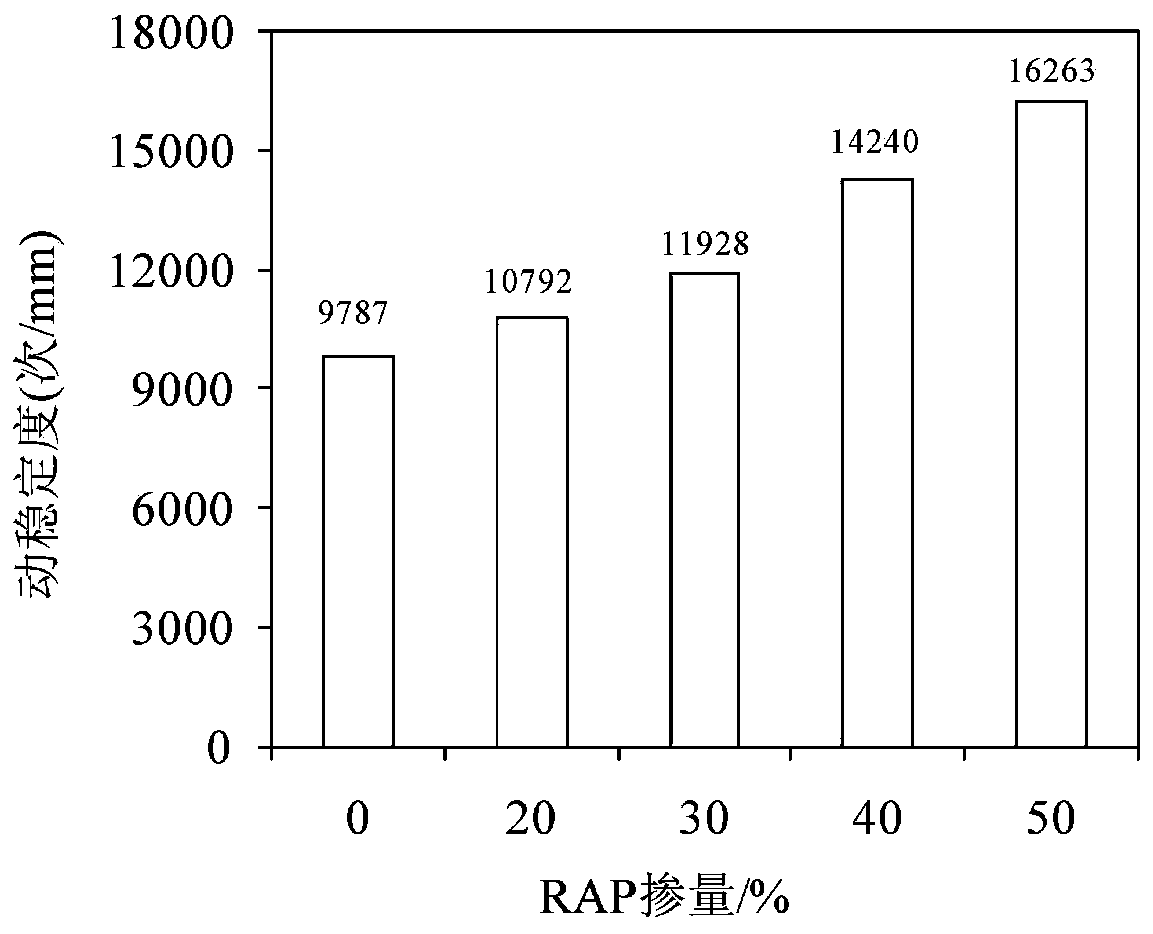

[0034] S4: Refer to the series of studies on the mix ratio of GAC-20. When calculating the asphalt dosage by using the mix ratio of the newly synthesized asphalt mixture, it is necess...

Embodiment 2

[0041] A method for finely sorting and reusing road milling asphalt waste, specifically comprising the following steps:

[0042] S1: Use a cold milling machine to plan serious cracks, ruts, potholes, and loose asphalt pavement, and collect and screen the asphalt waste produced by milling;

[0043] S2: Use a 11mm sieve to divide asphalt waste into coarse asphalt 10-20mm and fine asphalt 0-10mm, and test the combustion and performance of the two grades of asphalt waste, and also detect the physical indicators in the asphalt waste;

[0044] S3: mix the detected asphalt waste with the currently prepared AC-20 asphalt, and properly adjust the ratio of each grade of material so that the final synthetic gradation is close to the GAC-20 synthetic gradation, that is, a new synthetic asphalt is obtained;

[0045] S4: Refer to the series of studies on the mix ratio of GAC-20. When calculating the asphalt dosage by using the mix ratio of the newly synthesized asphalt mixture, it is necess...

Embodiment 3

[0052] A method for finely sorting and reusing road milling asphalt waste, specifically comprising the following steps:

[0053] S1: Use a cold milling machine to plan serious cracks, ruts, potholes, and loose asphalt pavement, and collect and screen the asphalt waste produced by milling;

[0054] S2: Use a 11mm sieve to divide asphalt waste into coarse asphalt 10-20mm and fine asphalt 0-10mm, and test the combustion and performance of the two grades of asphalt waste, and also detect the physical indicators in the asphalt waste;

[0055] S3: mix the detected asphalt waste with the currently prepared AC-20 asphalt, and properly adjust the ratio of each grade of material so that the final synthetic gradation is close to the GAC-20 synthetic gradation, that is, a new synthetic asphalt is obtained;

[0056] S4: Refer to the series of studies on the mix ratio of GAC-20. When calculating the asphalt dosage by using the mix ratio of the newly synthesized asphalt mixture, it is necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com