Up-down insertion and left-right extrusion non-jointing metal decoration heat insulation wall body structure and construction method

A metal decoration and thermal insulation wall technology, which is applied in the direction of building structure, floor, covering/lining, etc., can solve the problems of affecting the sealing effect, the organic sealant is easy to age and fall off, and the work efficiency is low, so as to achieve simple and convenient installation, High construction efficiency, not easy to age and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

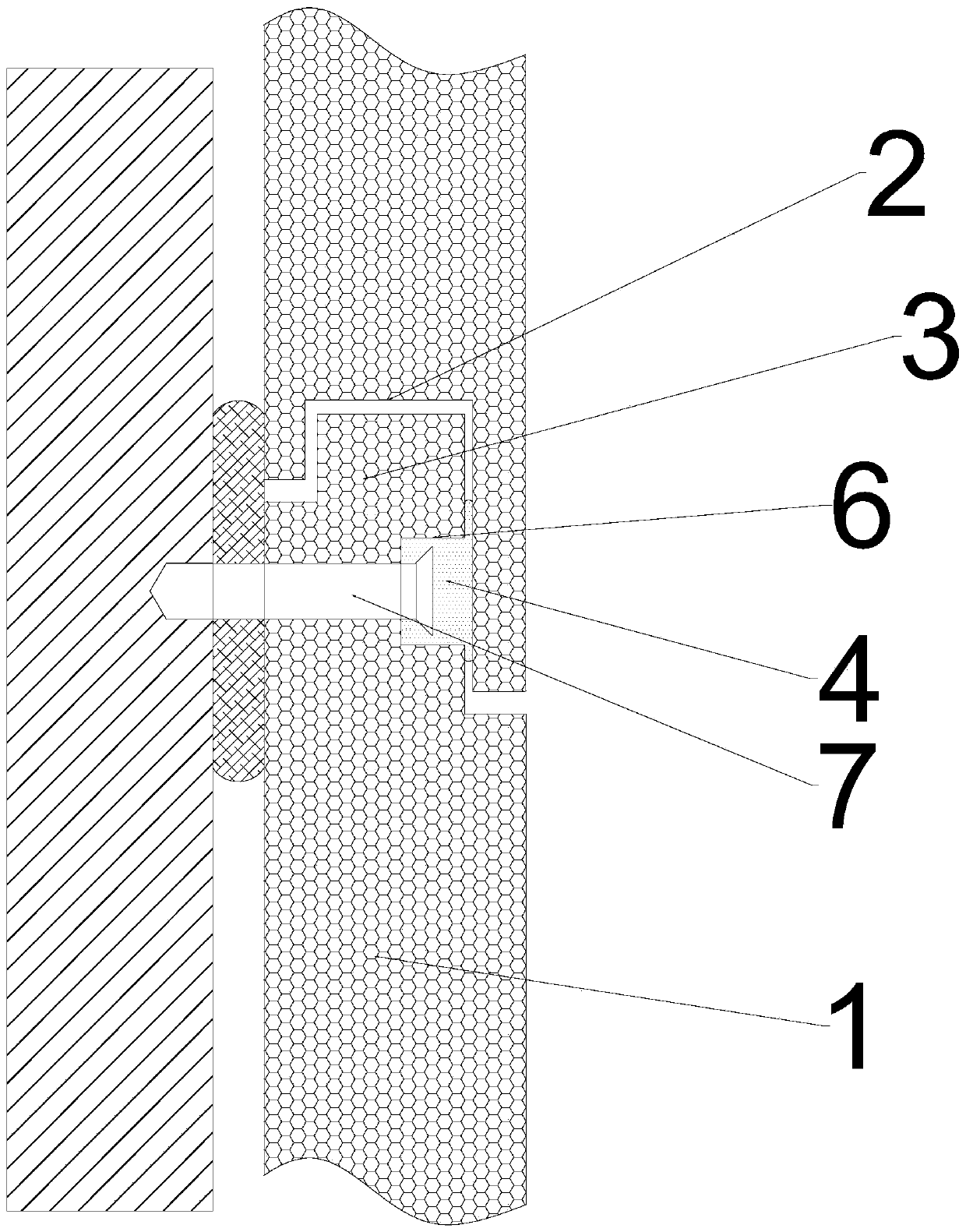

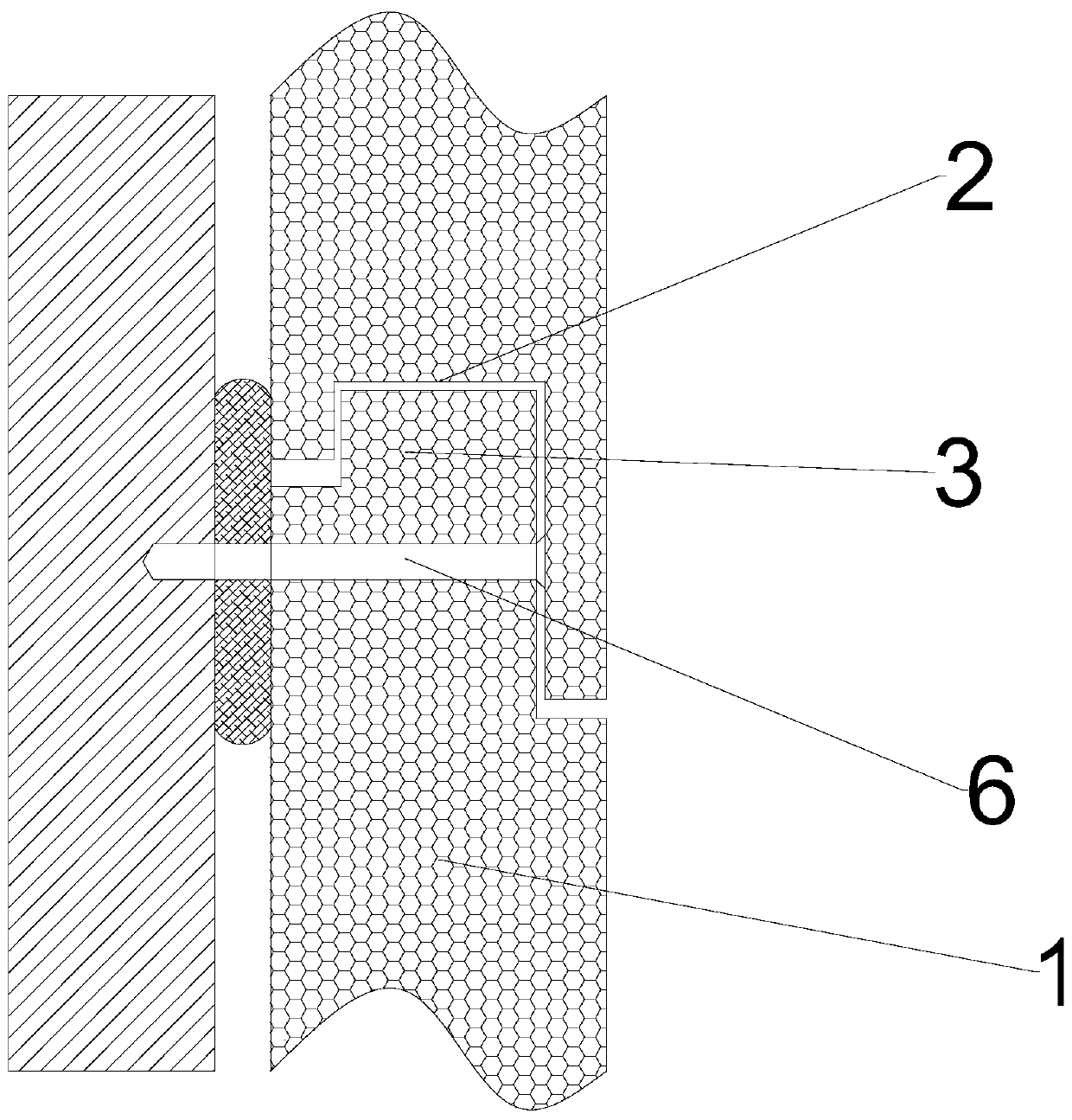

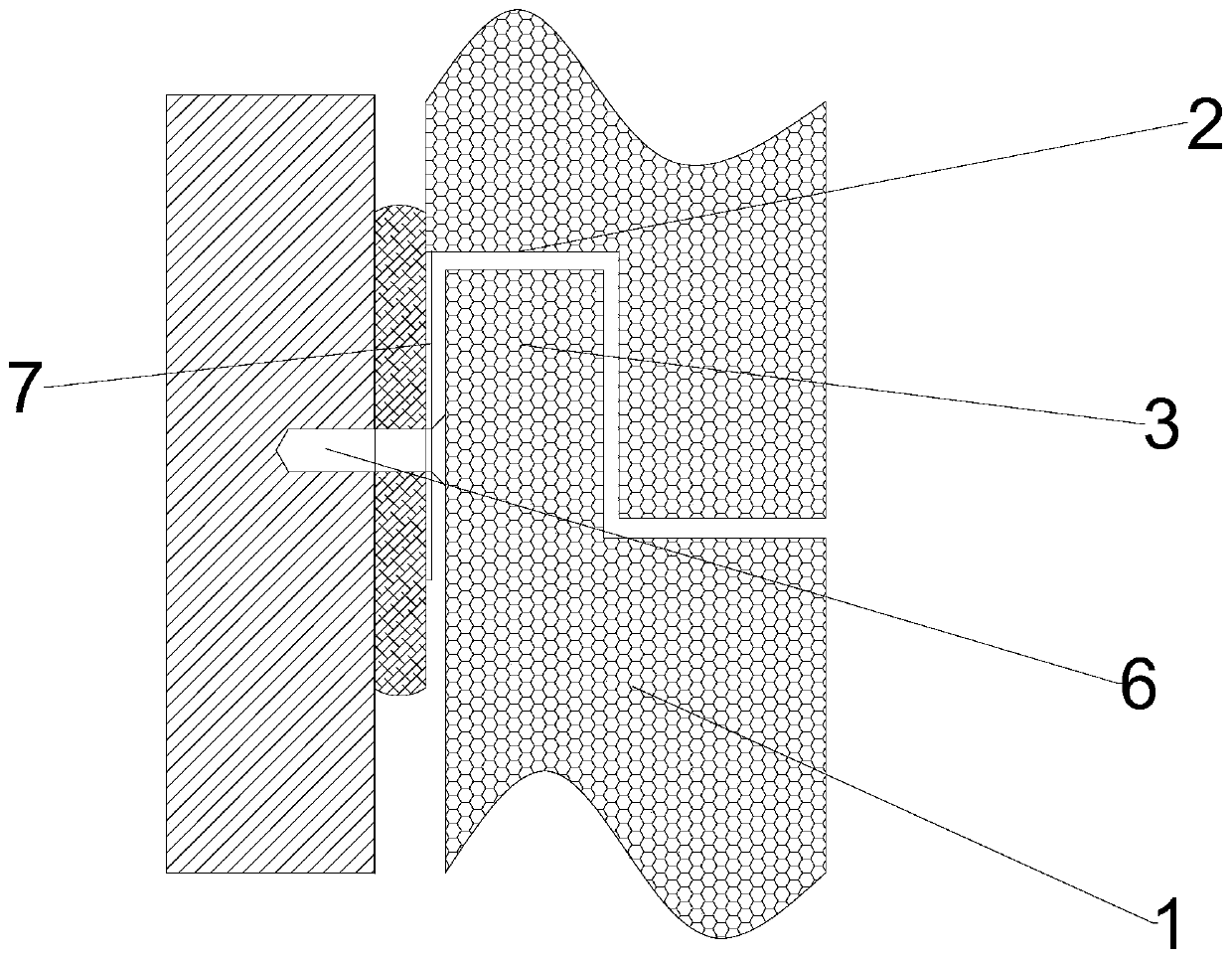

[0028] Please refer to Figure 1-4 , The present invention provides a metal decorative thermal insulation wall structure inserted up and down, extruded left and right, without pointing joints.

[0029] The metal device thermal insulation wall structure is composed of several rectangular metal decorative thermal insulation panels 1 fixed on the wall.

[0030] The upper edge of the metal decorative insulation board 1 is configured as a socket 3 , and the corresponding lower edge opposite to the edge is configured as a socket 2 . The socket 2 cooperates with the socket 3 of the adjacent metal decorative insulation board.

[0031] And the left and right side wall fold width of the metal decorative insulation board is not less than 20mm.

[0032] This design enables the metal decorative thermal insulation boards to be arranged vertically, and the connecting edges of each metal decorative thermal insulation board and its upper adjacent metal decorative thermal insulation boards ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com