A waste incinerator residue treatment furnace

A technology for incineration and treatment of furnaces, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problem that the incinerator does not remove the garbage attached to the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

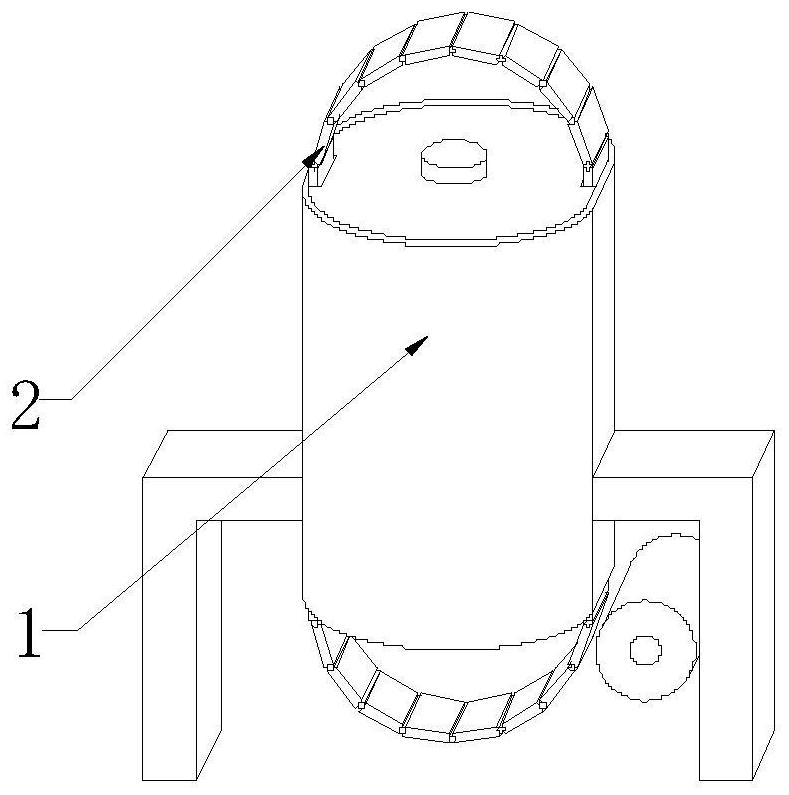

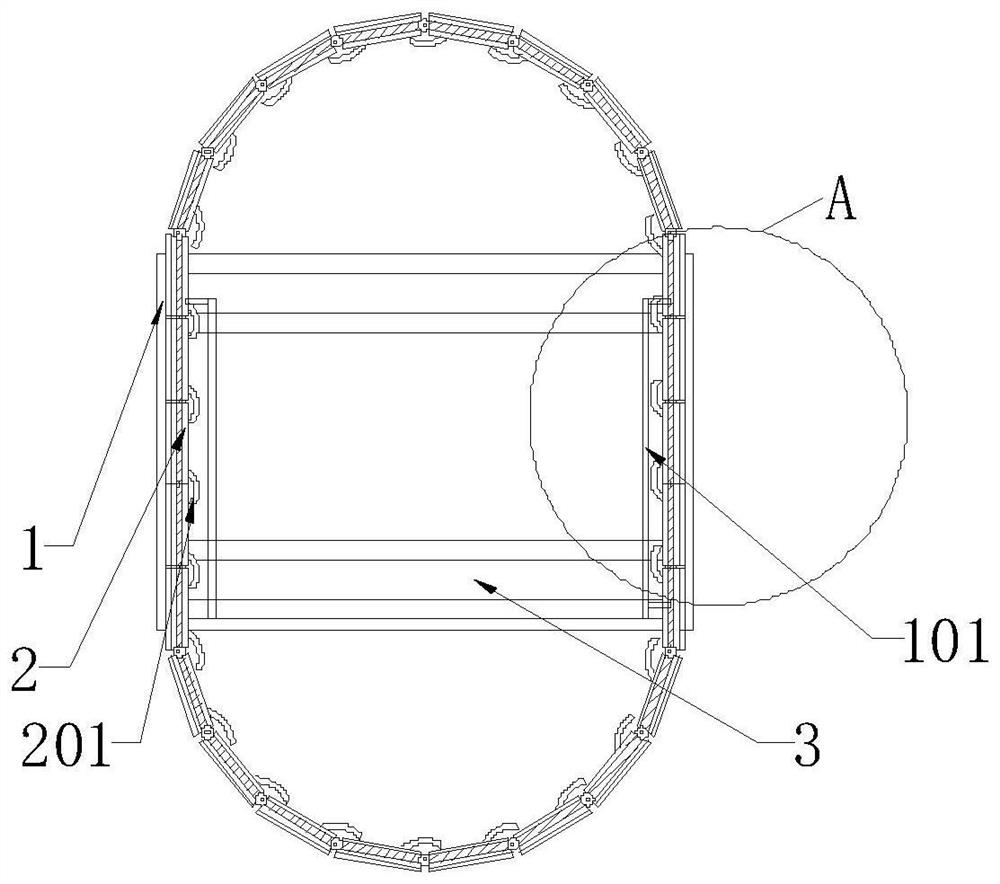

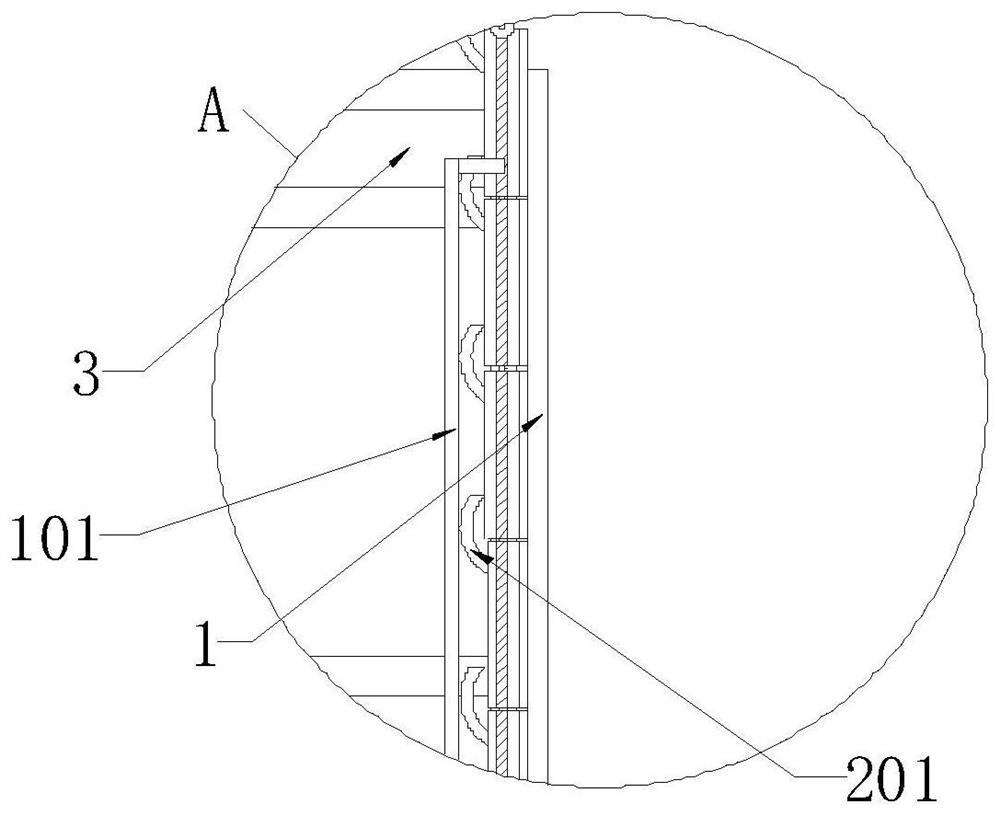

[0027] as attached figure 1 To attach Figure 8 Shown:

[0028] The present invention provides a waste incineration residue treatment furnace, which includes: an incineration cylinder 1, a limit rod 101, a positioning rod 102, a shift roller 103, a wall cleaning belt 2, a limit barb 201, a transposition hole 202, a cleaning Wall belt positioning frame 203, spring buckle 204, contact rod 205, wall clearing ring 3, direction changing block 301 and locking wheel 302; the inside of the incineration cylinder 1 is provided with a limit rod 101, and one side of the limit rod 101 is provided with a positioning rod 102, one side of the limit rod 101 is provided with a displacement roller 103, the inside of the incinerator 1 is provided with a wall cleaning belt 2, one side of the wall cleaning belt 2 is provided with a limit barb 201, and one end of the wall cleaning belt 2 is provided with Transposition hole 202, one side of wall cleaning belt 2 is provided with cleaning belt posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com