Nut tightening and shaping die special for narrow-space positive pressure air supply pipe and construction method

A technology for shaping molds and air supply pipes, which can be used in space heating and ventilation details, household appliances, applications, etc., and can solve the problem of ensuring that the air pipes are connected firmly and tightly, cannot be fastened by flange bolts, and affect the progress of construction and construction effects, etc., to reduce the risk of air duct body load, improve surface smoothness and visual quality, and achieve the same effect of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

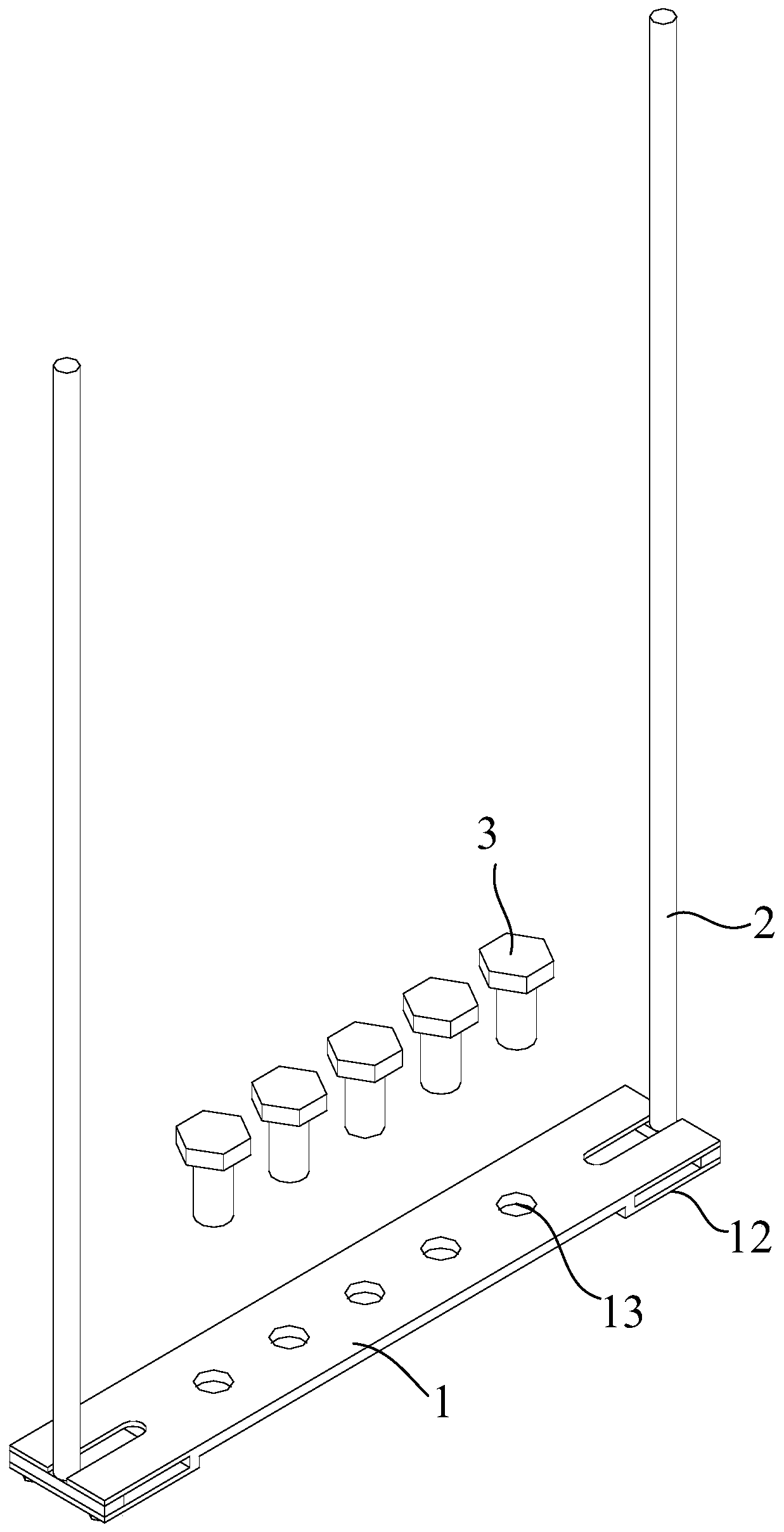

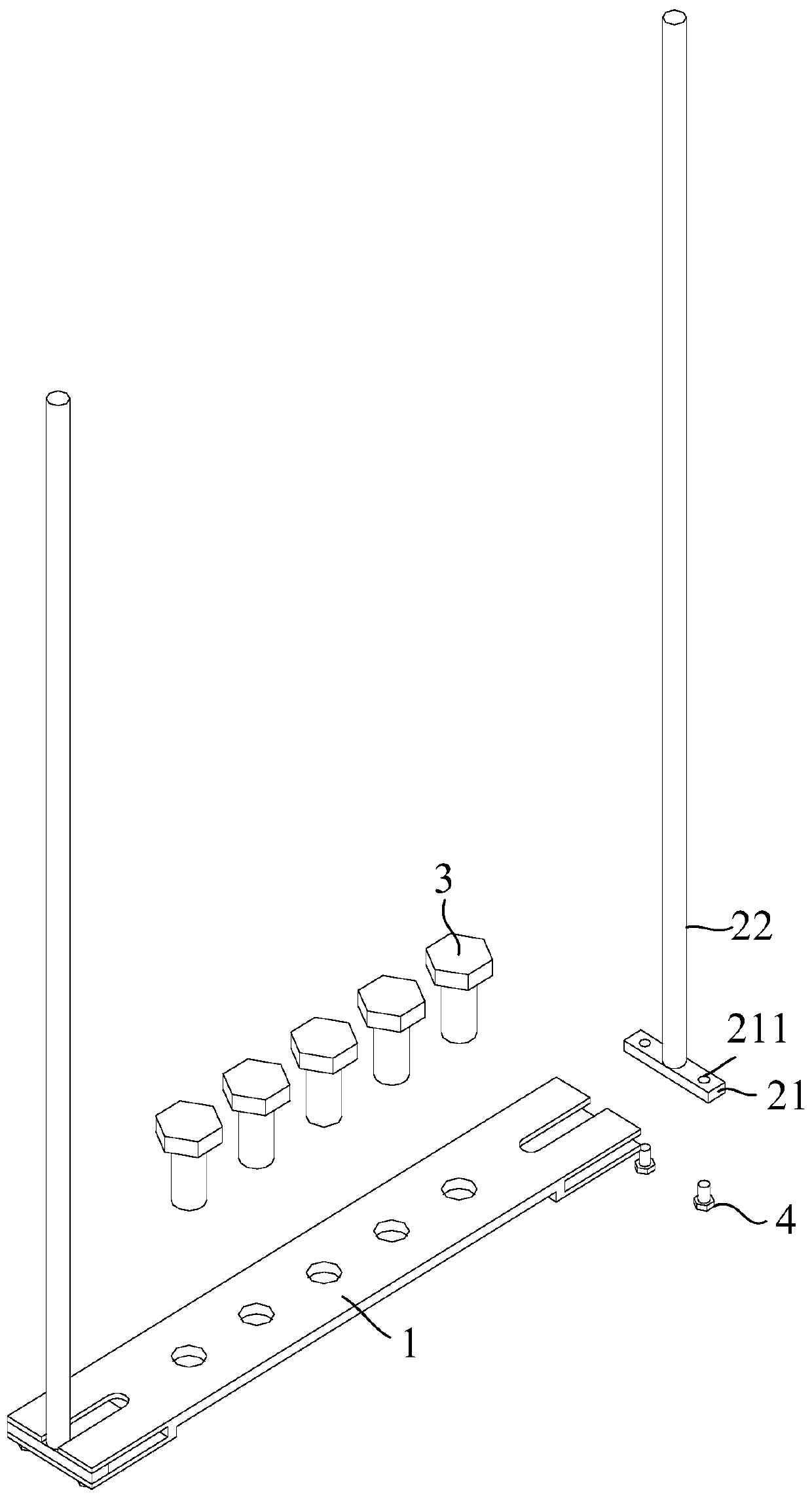

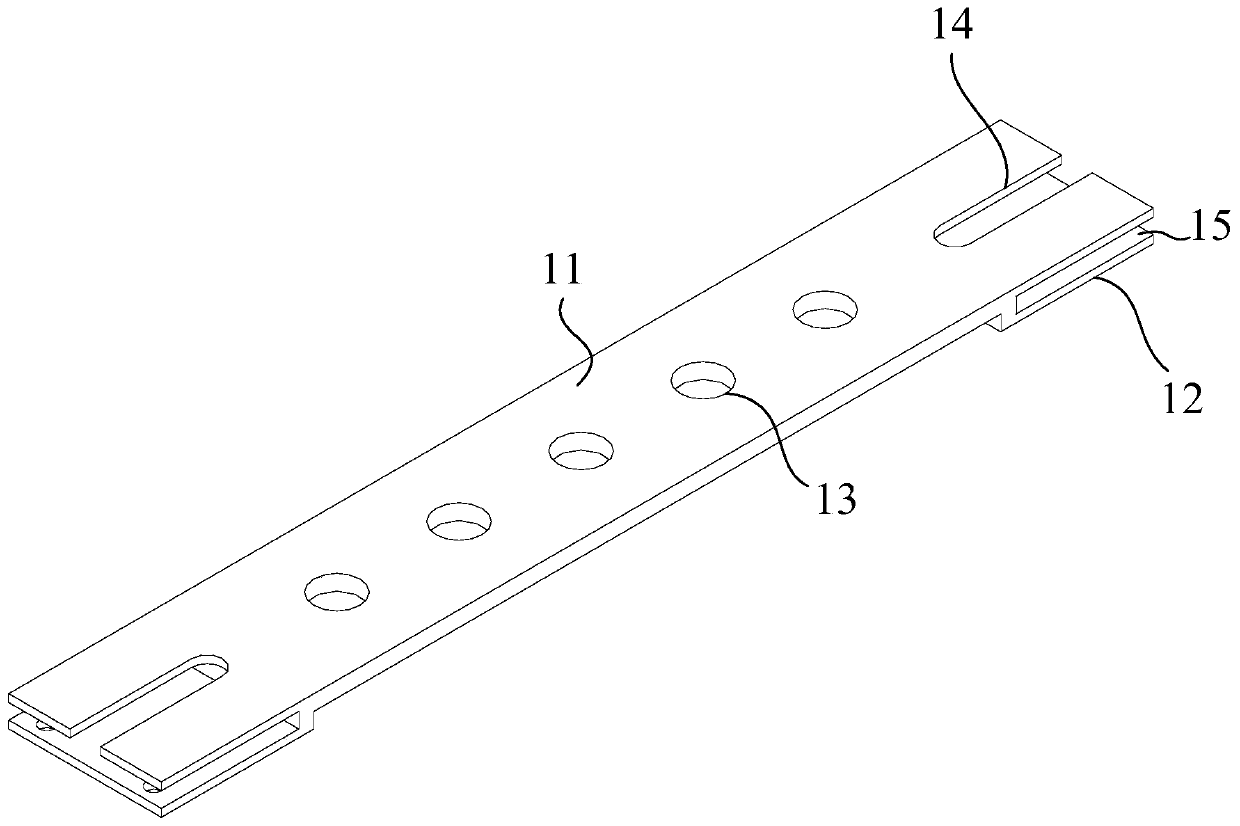

[0056] Example 1, such as Figure 1-Figure 5 As shown, the present invention provides a special nut tightening mold for narrow space positive pressure air supply pipes, including a new type of shaping plate, both sides of the new type of shaping plate are provided with movable novel locking rods, and the new type of shaping Both sides of the plate are provided with clamping blocks cooperating with the new clamping rods, the middle part of the new shaped plate is provided with a shaped hole, the shaped hole is provided with shaped bolts, and the new shaped plate is also provided with a The U-shaped groove for the movement of the new snap lever.

[0057] Preferably, the novel locking rod includes a support plate, a locking handle is arranged on the upper part of the supporting plate, and bolt fixing holes arranged on both sides of the locking handle are arranged on the supporting plate.

[0058] Preferably, the positioning block is provided with a fixed long groove cooperating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com