Fully automatic evaporation overflow measuring device

A measuring device and fully automatic technology, applied in the field of meteorology and water conservancy, can solve the problems of the fluctuation of the evaporative water surface, the inability to measure the overflow volume accurately and timely, and the inaccurate water level measurement results, so as to avoid inaccurate water level measurement, real-time water replenishment, The effect of accurate hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The implementation examples are described below and accompanied by the accompanying drawings, and the detailed description is as follows.

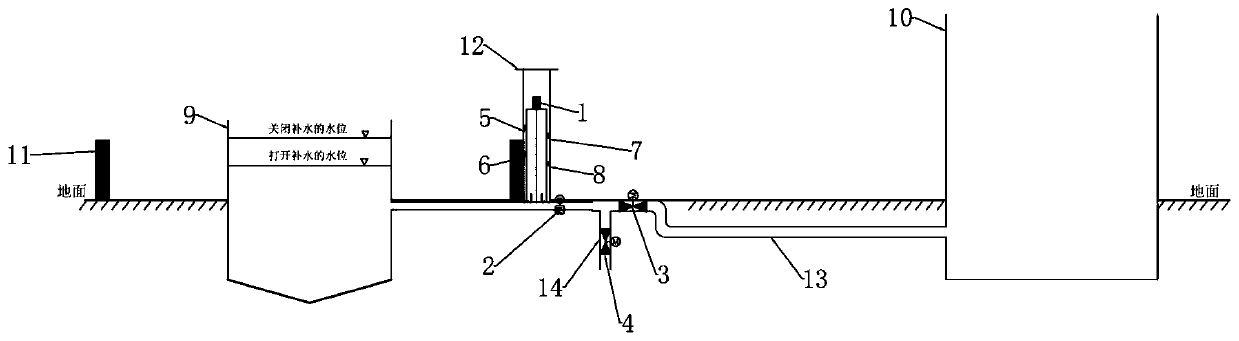

[0020] Such as figure 1 as shown, figure 1 It is the automatic evaporation overflow measuring device of the present invention

[0021] A fully automatic evaporation overflow measuring device, comprising an evaporating dish 9, a water replenishment barrel 10, a measuring barrel 12 connected to the evaporating dish through a pipeline, a magnetostrictive water level 1 is placed in the measuring barrel, and there are 2 pairs of water level control switches in the measuring barrel. Open the overflow switch 5, close the overflow switch 6, close the water supply switch 7 and open the water supply switch 8, the water supply pipeline 13 on the right side of the measuring bucket 12 is connected with the electromagnetic flowmeter 2, the overflow drainage pipeline 14 and the water supply solenoid valve 3, the measuring bucket The overflow dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com