Dielectric waveguide filter for improving harmonic performance, radio frequency module and base station

A dielectric waveguide and filter technology, applied in the field of filters, to reduce the complexity of the manufacturing process, improve the overall performance, reduce the number of stages and zero points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

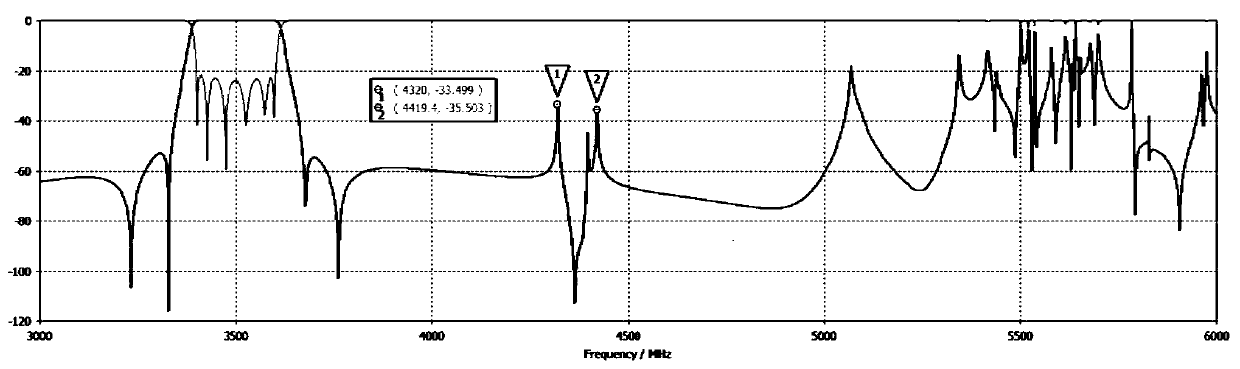

Embodiment 1

[0035] Such as figure 1 As shown, a dielectric waveguide filter for improving harmonic performance, the filter includes a plurality of dielectric bodies 1 combined, the surface of the dielectric body 1 is covered with a conductive layer, and the dielectric body 1 includes a plurality of resonant parts arranged in an array, The dielectric body 1 is provided with a coupling window 2, an input interface and an output interface. There is no conductive layer at the position of the coupling window 2. The input interface and the output interface are arranged on different resonant parts of the same dielectric body 1. The resonant part where the input interface is located and At least one isolating part is provided between the resonating parts where the output interface is located, and the isolating part makes the coupling bandwidth between the two resonating parts connected to it smaller than 10% of the working bandwidth of the dielectric waveguide filter using the dielectric body 1 . ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that in this embodiment, the coupling windows 2 are distributed symmetrically along the central axis of the dielectric body 1 .

Embodiment 3

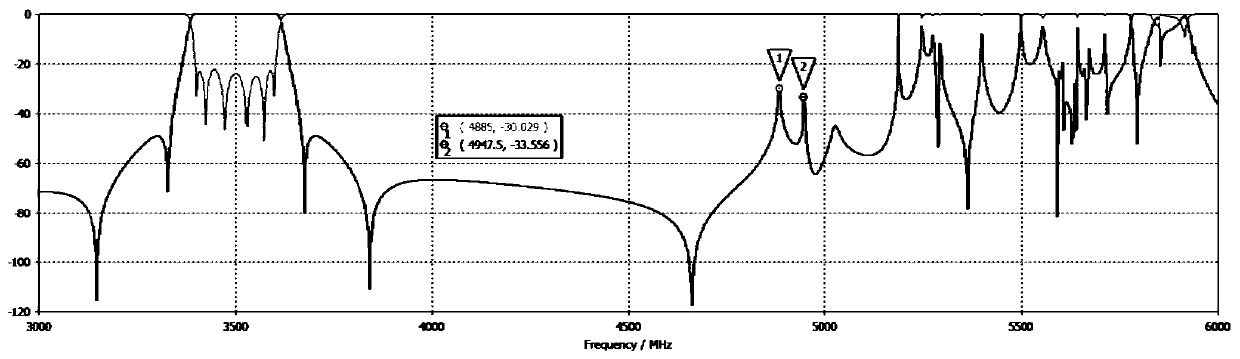

[0047] Such as Figure 8 As shown, the difference between the present embodiment and the first embodiment is that the coupling window 2 for the main coupling or / and the coupling window 2 for the cross-coupling only includes one strip-shaped coupling window 2 located at the edge of the dielectric body 1 .

[0048] Specifically, in this embodiment, a strip-shaped coupling window 2 is used for the second coupling window. In other embodiments of the present application, the coupling window 2 for other main-way coupling or the coupling window 2 for cross-coupling may also use a bar-shaped coupling window 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com