Block clearing device for combustion chamber negative pressure sampling pipeline

A furnace negative pressure and sampling tube technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cumbersome procedures, personal risks, tripping, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

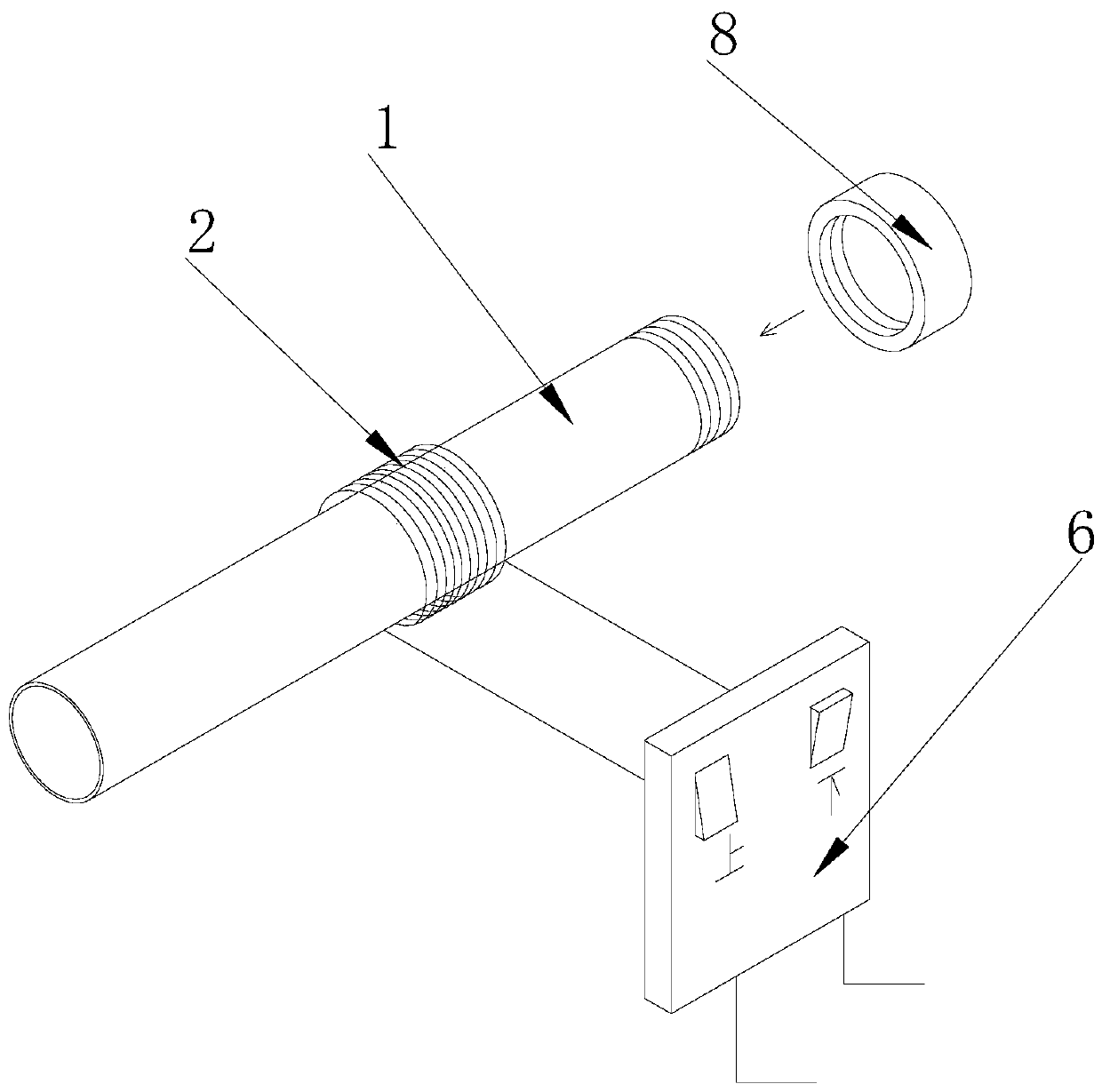

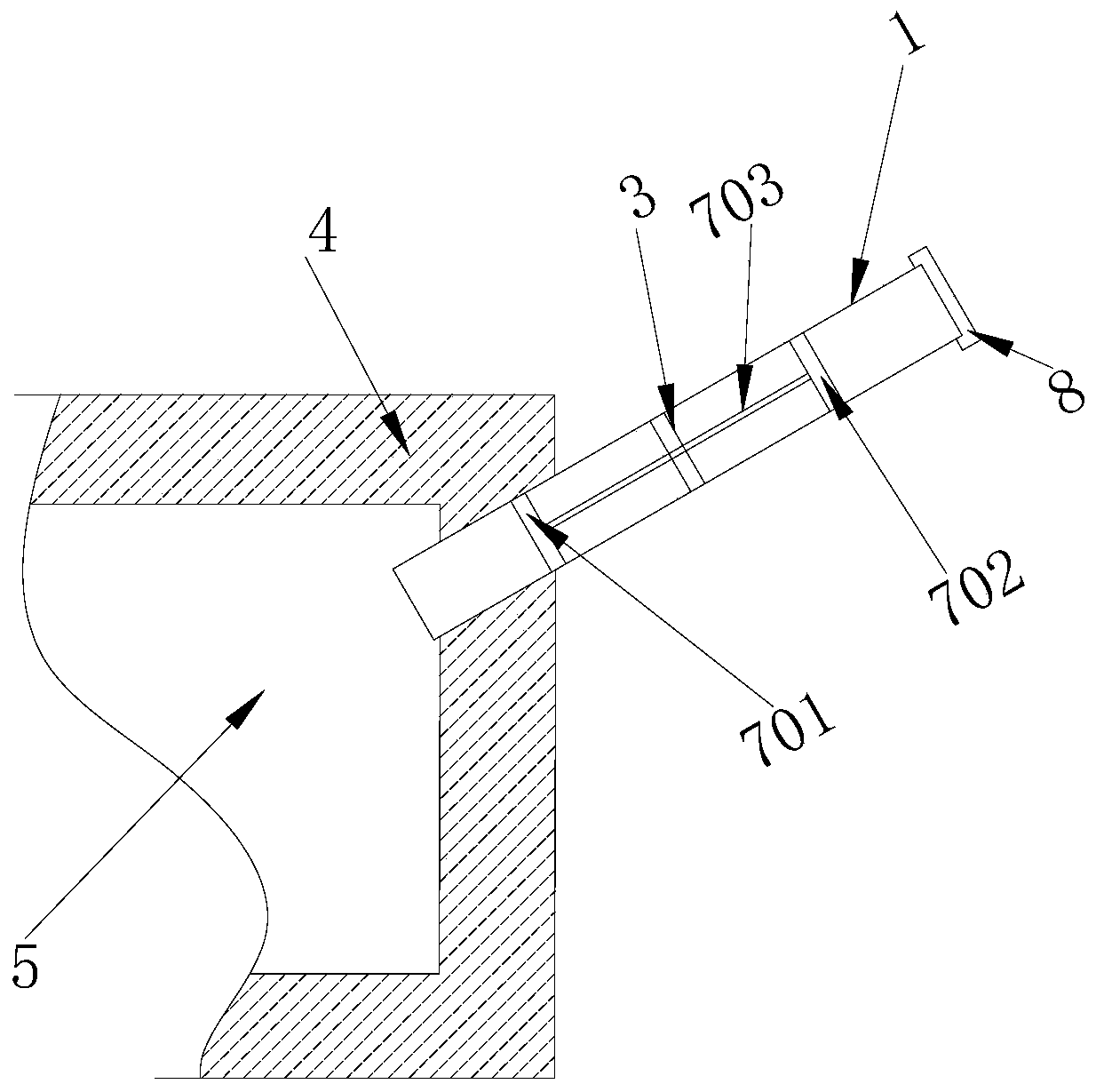

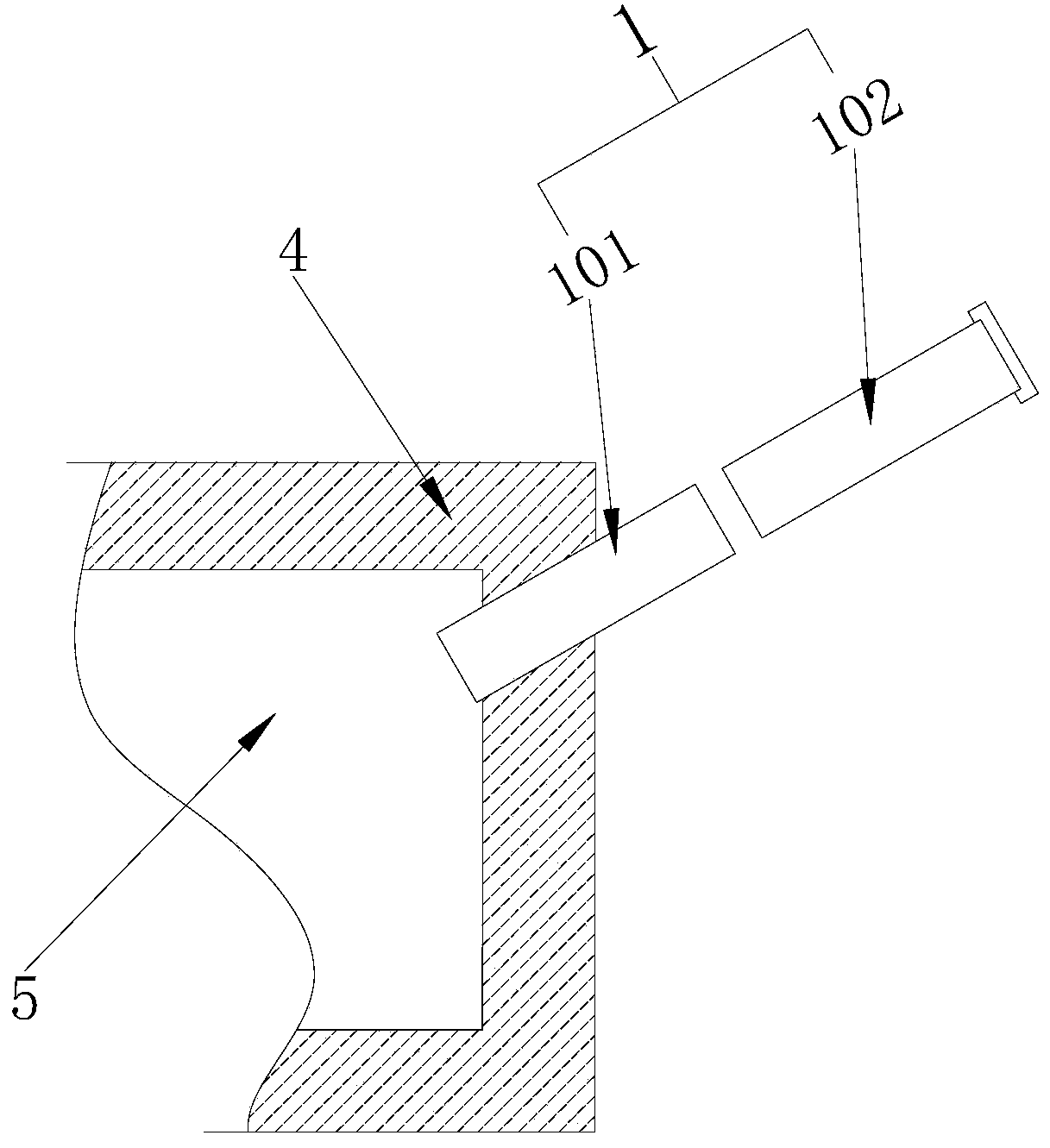

[0027] A furnace negative pressure sampling pipeline clearing device, please refer to the attached figure 1 - attached Figure 5 And shown in accompanying drawing-8, comprise sampling tube 1, coil 2, clearing assembly 7 and anti-falling frame 3, sampling tube 1 comprises inner sampling tube 101 and outer sampling tube 102, and one end of inner sampling tube 101 is inclined downwards and passes through Pass the insulation wall 4 and extend to the inside of the furnace 5, the other end of the inner sampling tube 101 is placed outside the insulation wall 4 and welded with one end of the outer sampling tube 102 to form a sampling tube 1 as a whole; the anti-falling frame 3 is welded to the inner sampling tube 101 and On the inner wall of the welding part of the outer sampling tube 102; the coil 2 is evenly wound on the outer wall of the middle part of the sampling tube 1, and the two ends of the coil 2 are electrically connected with the polarity switch 6; the polarity switch 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com