Full-electric rebar straightening and bending integrated machine

An all-electric, all-in-one machine technology, which is applied in the field of steel bar processing equipment for construction, can solve the problems of oil leakage, safety and sanitation, high temperature and environmental impact, and low hydraulic work efficiency, so as to achieve simple and convenient maintenance and reduce equipment occupation space , the effect of reducing the complexity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

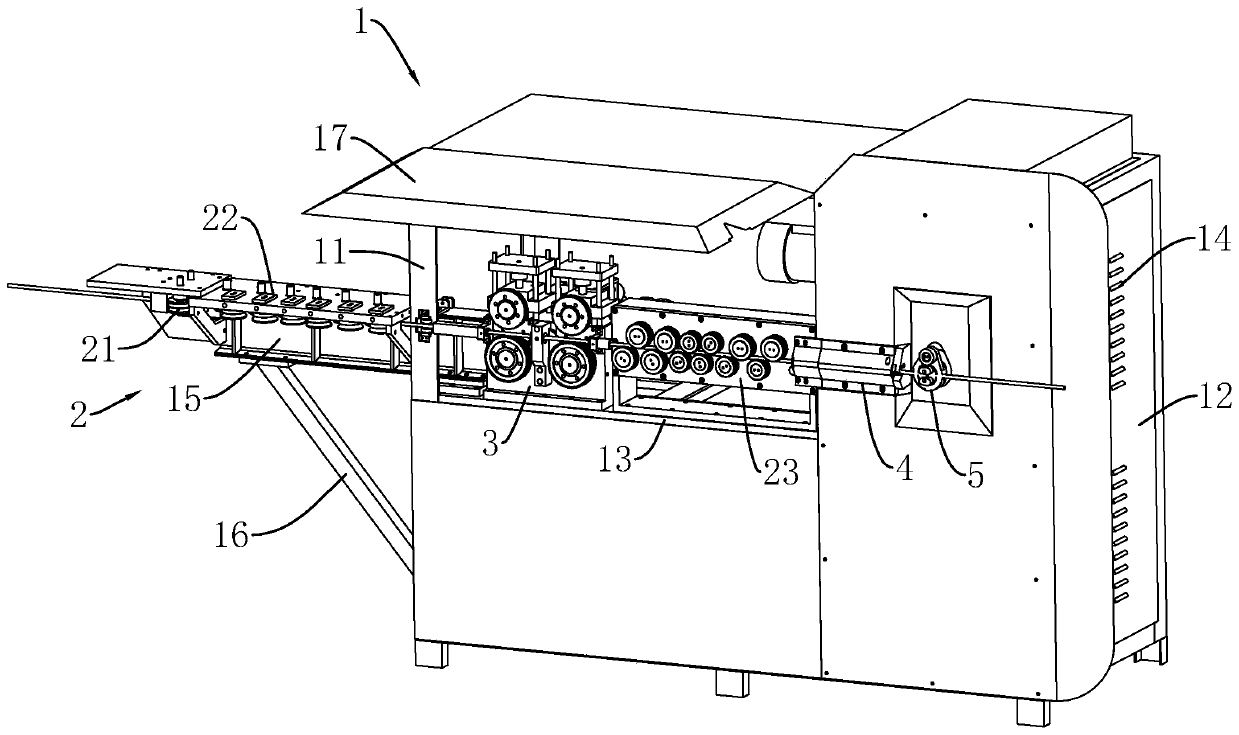

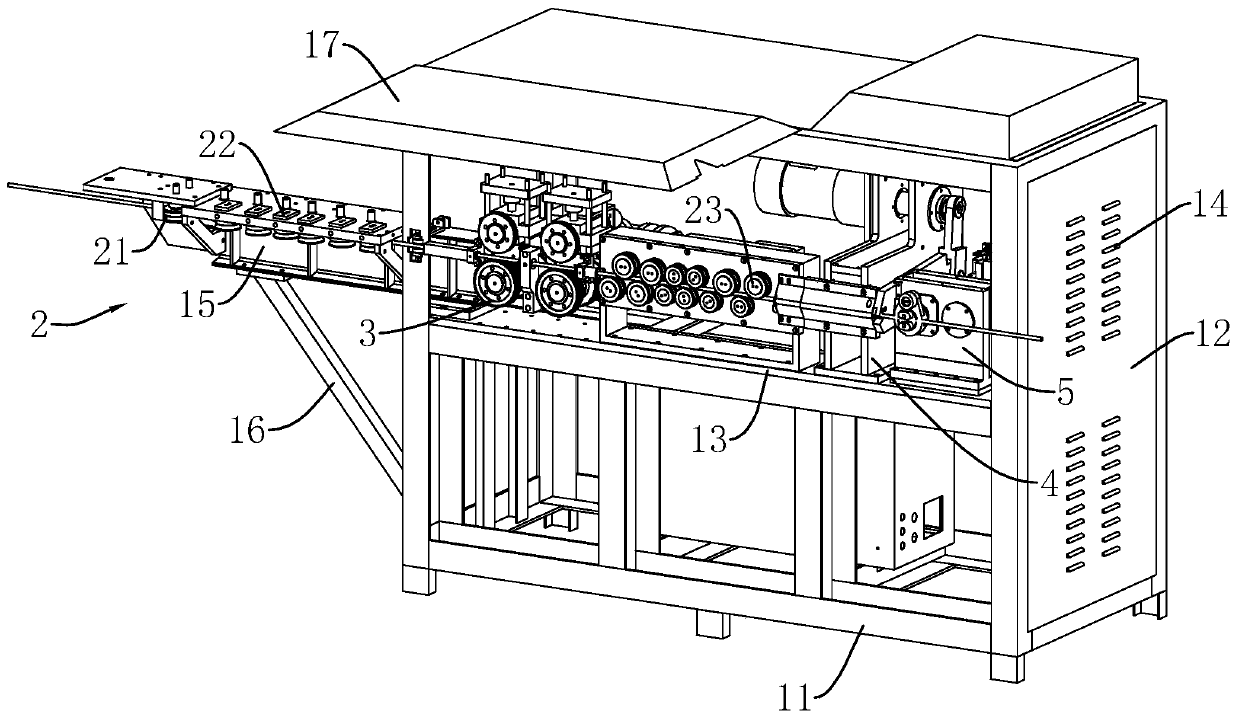

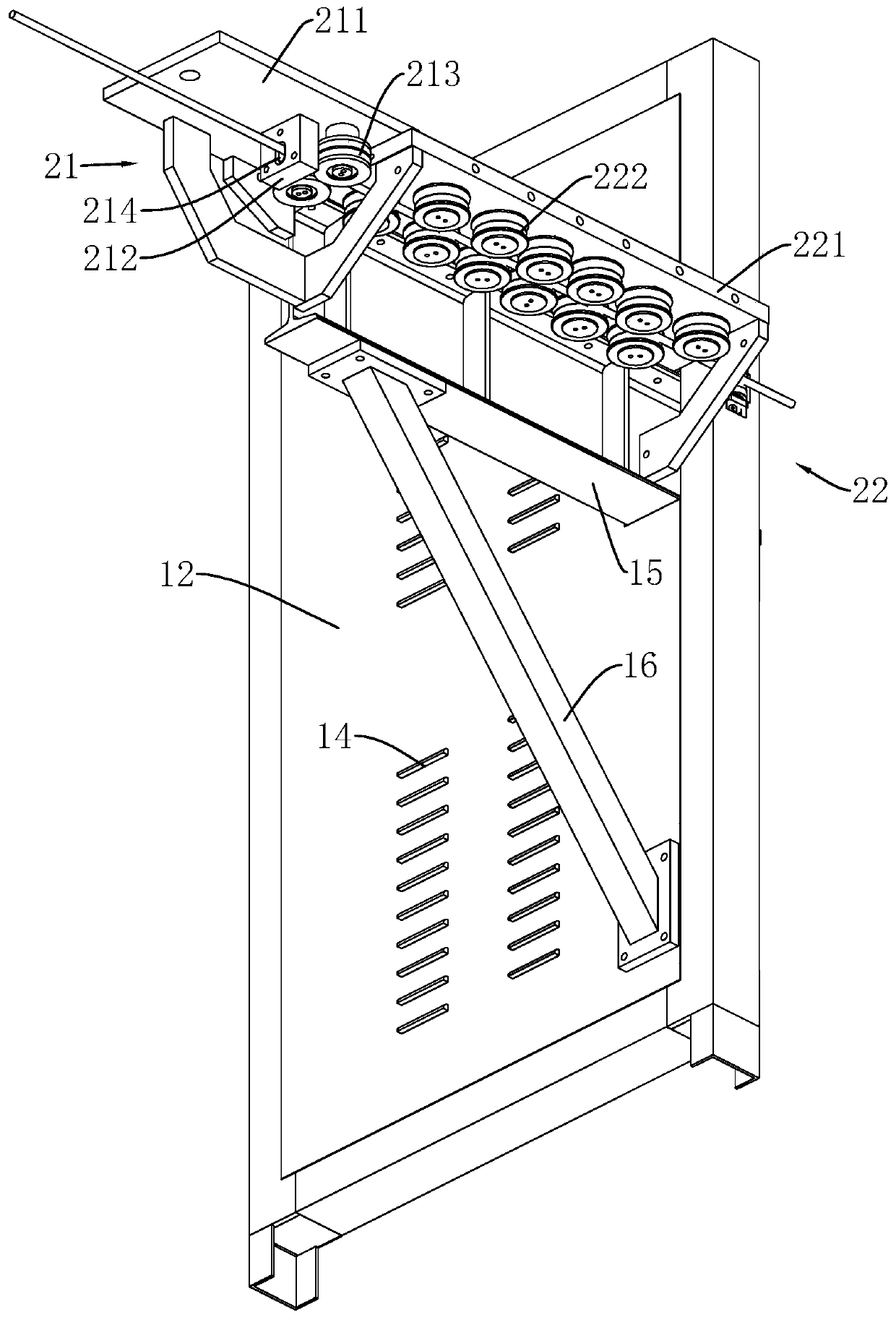

[0040] Embodiment: an all-electric steel bar straightening and hoop all-in-one machine, such as figure 1 , figure 2 As shown, it includes a frame 1, and the frame 1 includes a rectangular frame body 11 spliced by a plurality of horizontally and vertically staggered support rods. Closed housing. The interior of the frame body 11 is also horizontally provided with a partition 13, which divides the interior of the frame body 11 into two cavities distributed up and down. The cavity above is the working area. Straight mechanism 2, electric shearing mechanism 4 and hoop mechanism 5; the cavity located below is the equipment area, which is used to install the electric control box, etc.; the side of the frame body 11 facing the steel bar conveying line is the working end of the frame 1, The steel bar is sequentially processed along the steel bar conveying line of the frame 1, such as straightening, hoop bending and shearing.

[0041] The hood 12 at both ends of the long side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com