Automobile gearbox supporting frame clamp capable of being stably operated after being improved

An automobile gearbox and post-stabilization technology, which is applied in the directions of turning equipment, manufacturing tools, toolholder accessories, etc., can solve the problems of irregular gearbox shape structure, poor flexibility, irregular gearbox shape structure, etc., and achieve the device structure flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

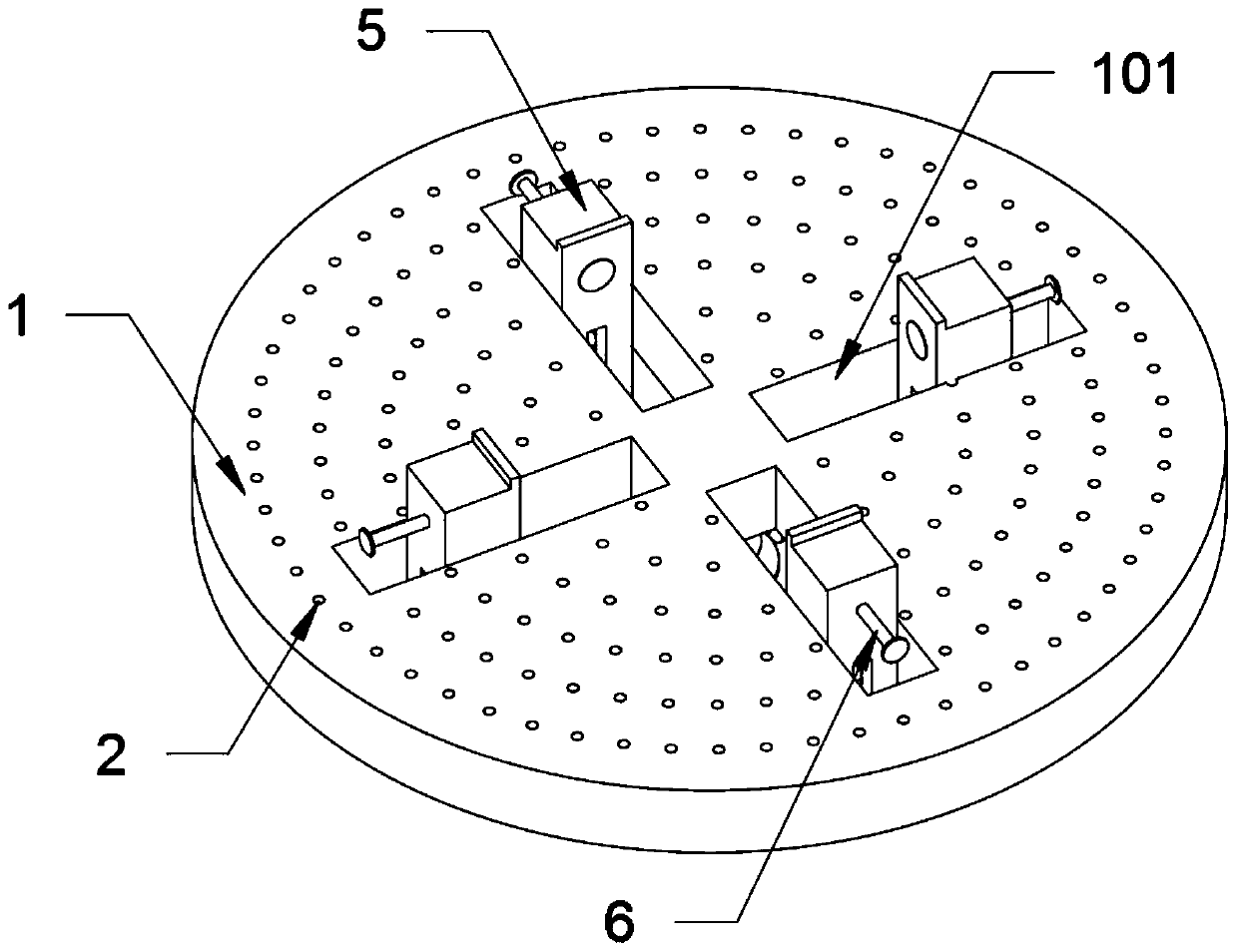

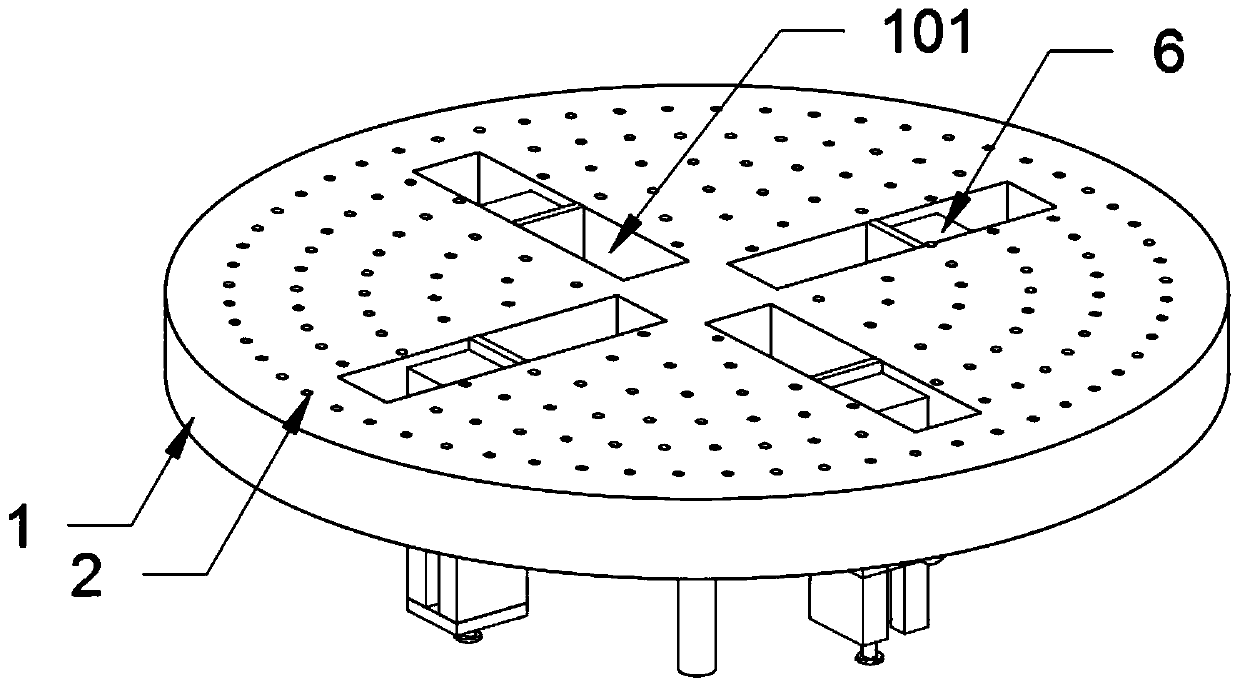

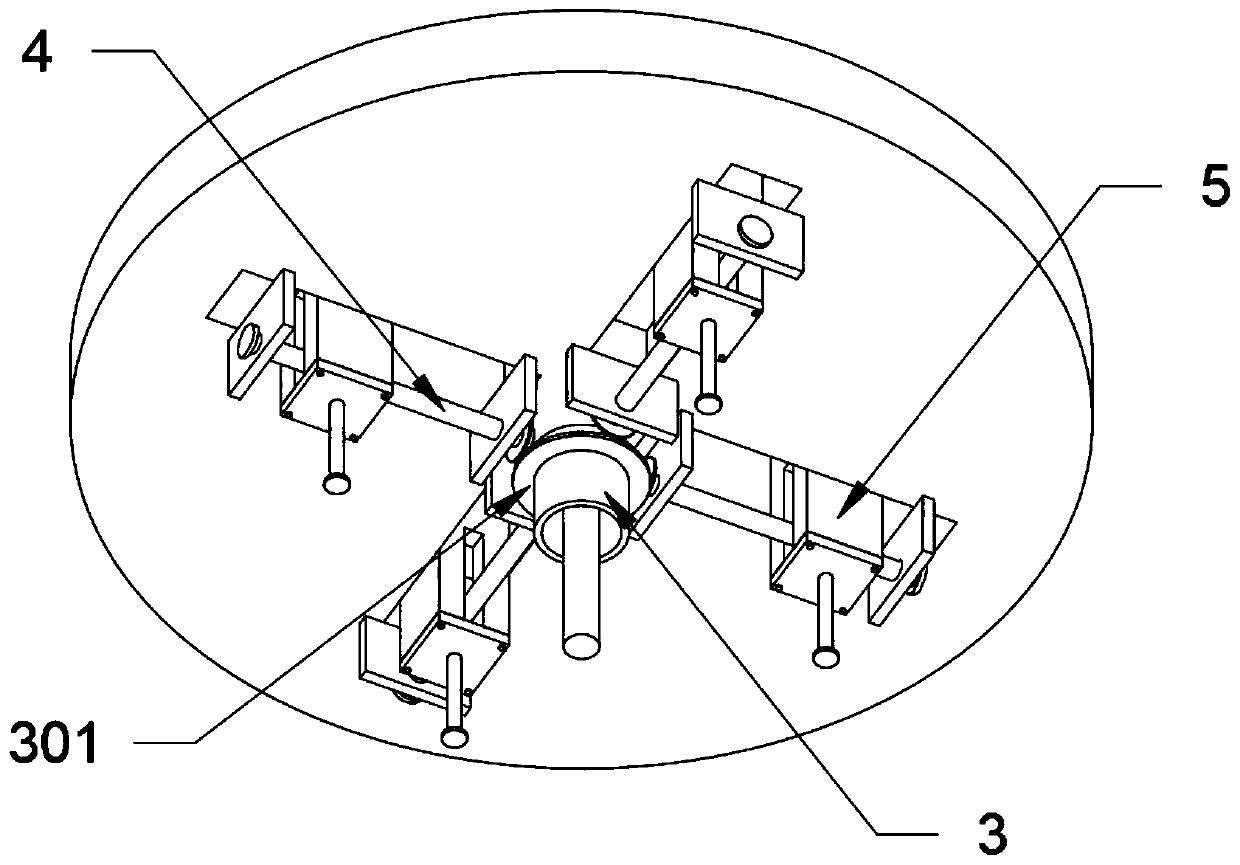

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032] The present invention provides an improved and stably operated automotive gearbox support frame clamp, which includes a bearing plate 1, a rectangular hole 101, a ball 2, a rotating support seat 3, a bevel gear A301, a threaded rod A4, a bevel gear B401, a clamp 5, and a clamp Seat 501, cover plate 502, fixture main body 503, slide groove 50301, threaded rod B504, support solid arm 6, threaded rod C601 and support claw 602; the carrying plate 1 is a cylindrical structure, and the top end surface of the carrying plate 1 Four rectangular holes 101 are opened in an annular array; the center position of the lower end surface of the bearing plate 1 is rotatably connected to a rotating support seat 3, and a bevel gear A301 is welded on the outer wall of the rotating support seat 3; 1 The bottom surface is welded in a circular array with four sets of two rotating connecting seats, and each set of rotating connecting se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com