Leather mobile phone rear cover cutting machine with automatic feeding and discharging functions

A technology of automatic loading and unloading and mobile phone back cover, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of not being suitable for mass production, increasing product cost, and long production cycle, so as to facilitate large-scale batch production The effect of production, cost saving and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

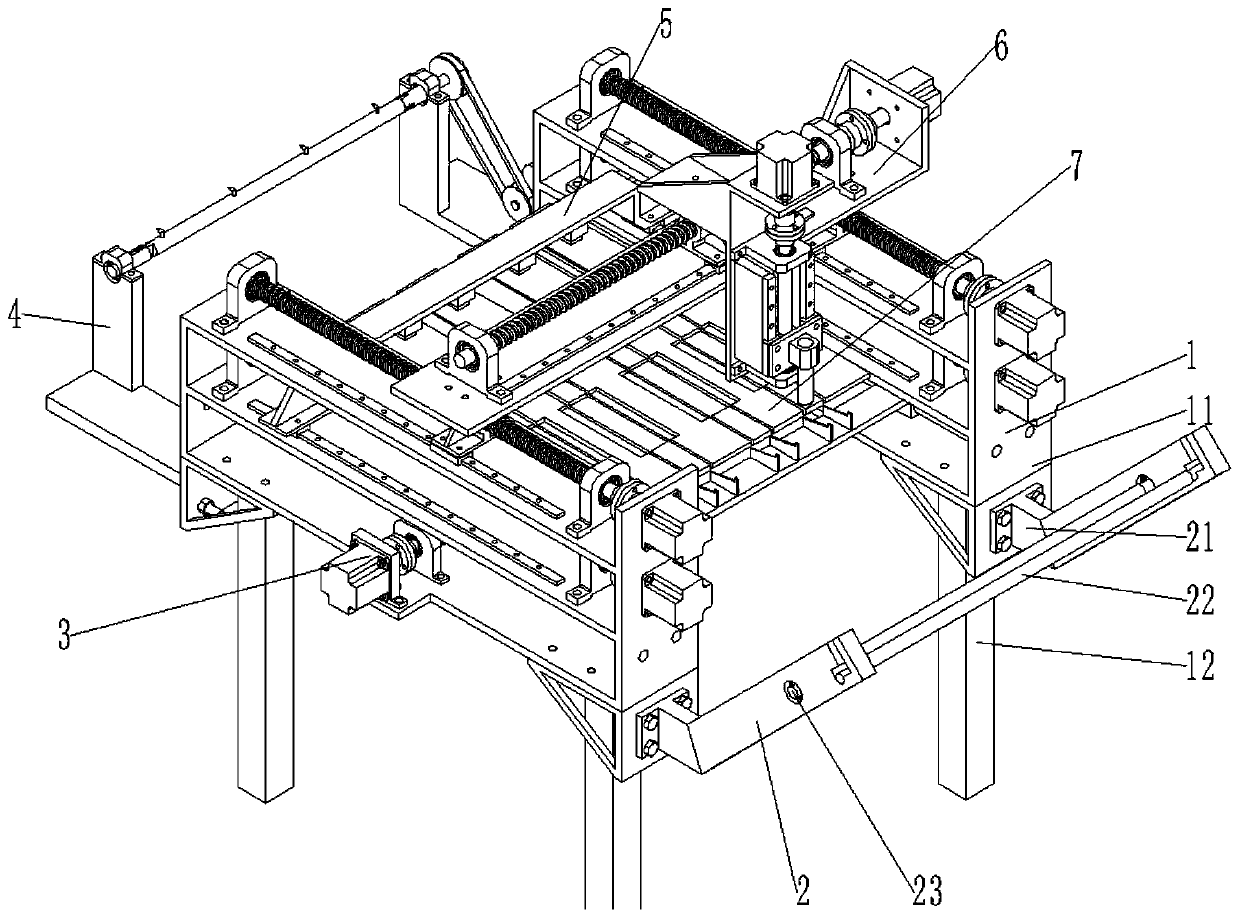

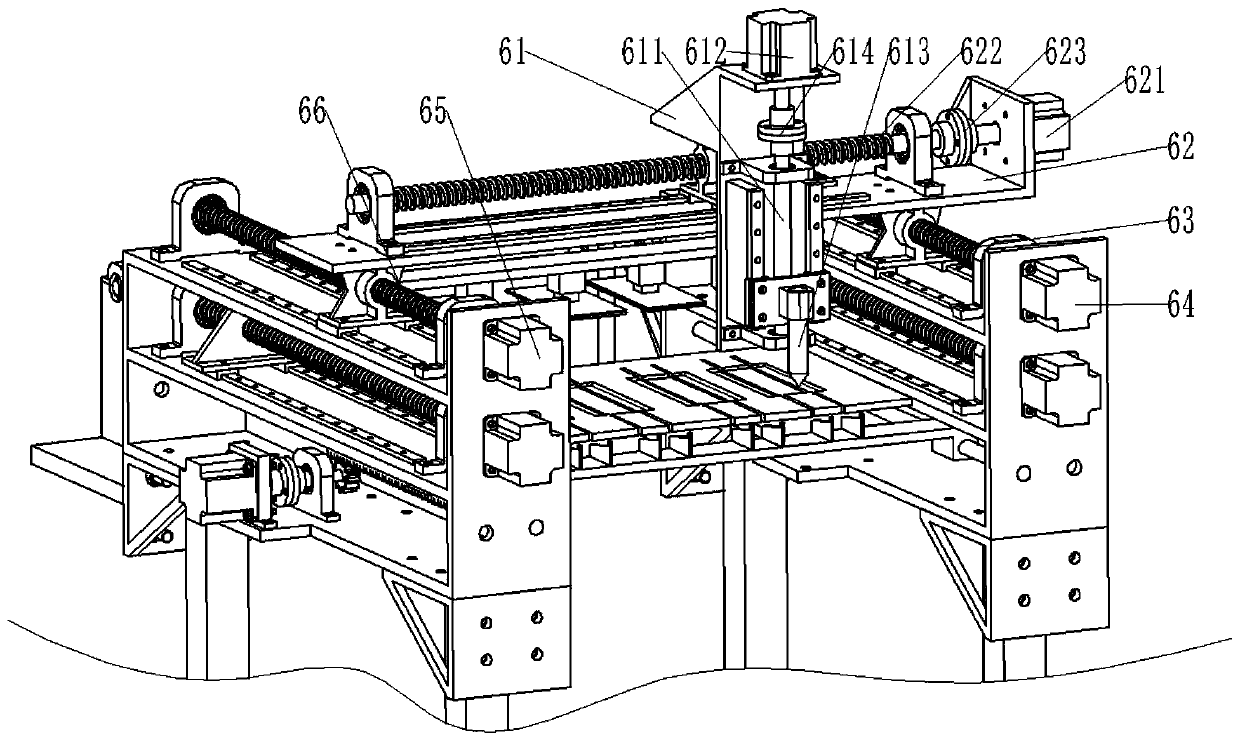

[0019] Such as Figure 1 to Figure 3 As shown, the leather mobile phone back cover cutting machine with automatic loading and unloading function of the present invention includes a frame 1, a material rack 2, a material return device 3, a traction device 4, a punch handling device 5, a laser cutting device 6 and a concave The base plate 7 and the frame 1 include a support frame 12 and a mounting frame 11, and the mounting frame 11 is fixed on the support frame 12 by means of bolt connection. The material rack 2 includes an insertion frame 21, a material rod 22 and a flattening rod 23, and the insertion frame 21 is fixed in parallel to the feeding end of the support frame 12 by means of bolt connection; the material rod 22 and the flattening rod 23 are arranged on the insertion frame 21 .

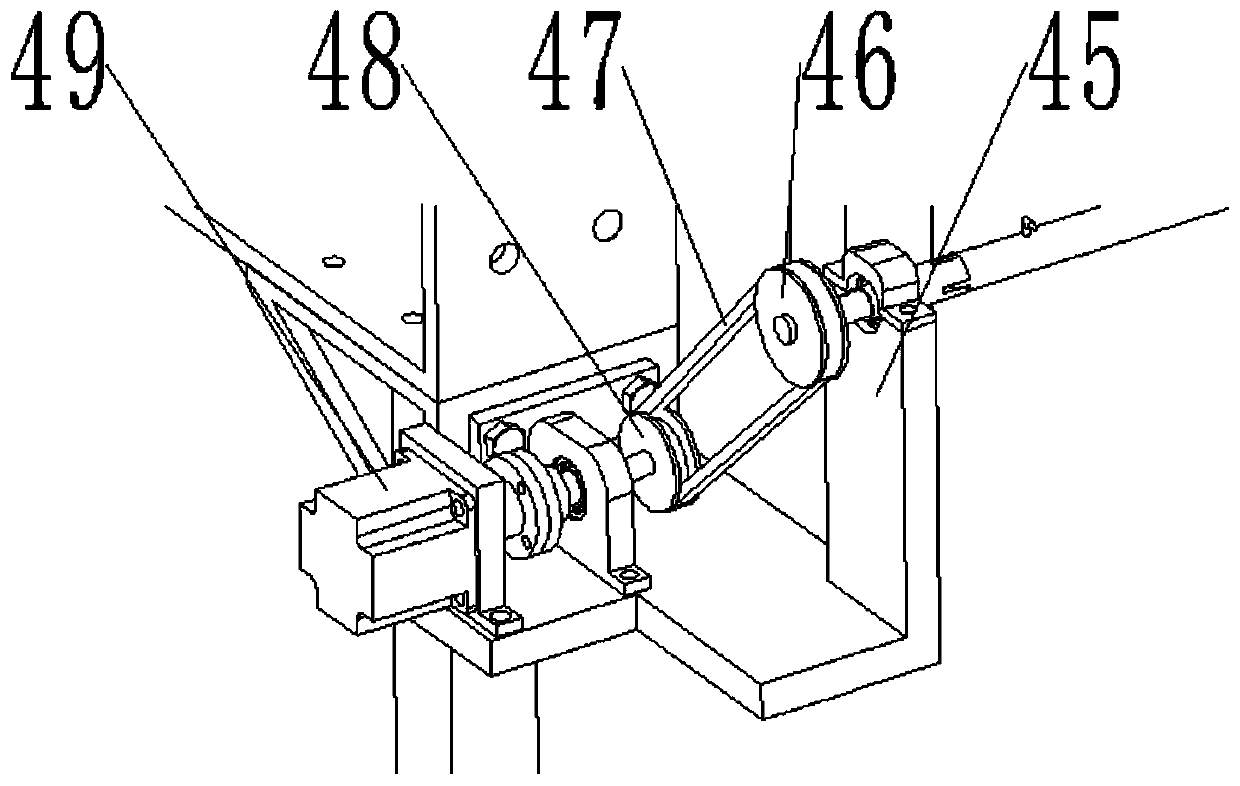

[0020] Such as Figure 1 to Figure 4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com