Electronic buzzer pin correcting and centring mechanism

A centering mechanism and correction mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve high work efficiency, good product consistency, accurate and fast centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

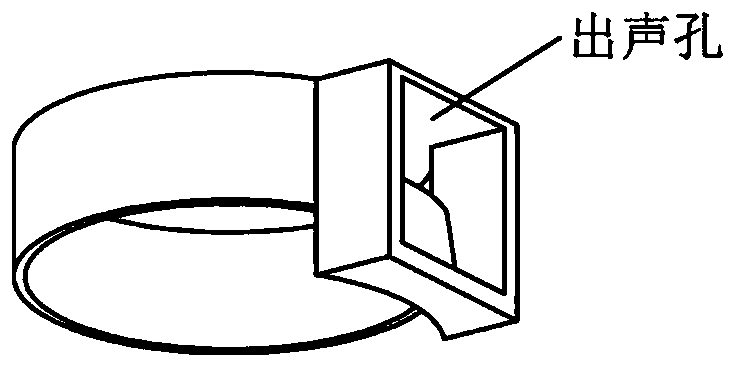

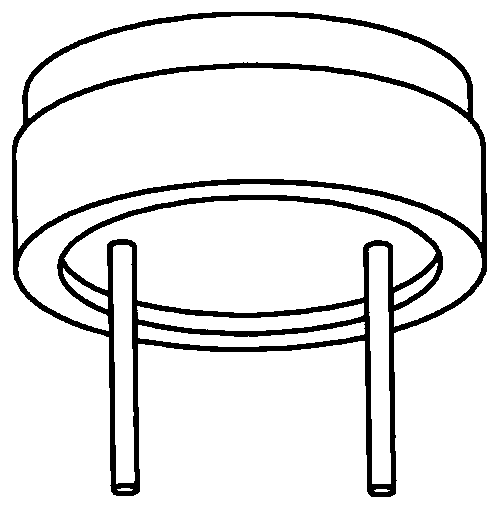

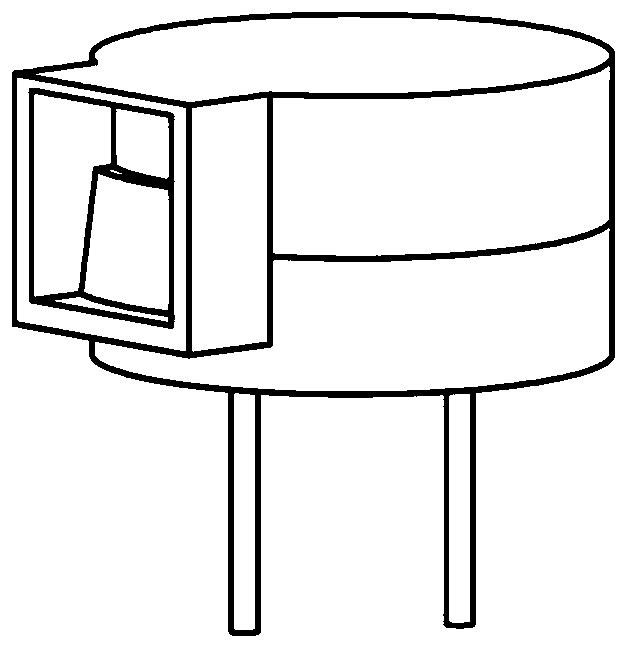

[0040] like Figure 4 As shown, an electronic buzzer pin correction and centering mechanism is characterized in that it includes a feeding mechanism, a material introduction mechanism, a pin correction mechanism, a centering mechanism and a base 102:

[0041] like Image 6 As shown, the feeding mechanism includes an electromagnetic vibration plate 201, the electromagnetic vibration plate is placed on the support frame 103, the electromagnetic vibration plate 201 is connected with a material guide groove 204, and the material guide groove 204 is installed on the linear electromagnetic vibration On the device 202, the material guide groove 204 is provided with a material guide piece 203 for guiding the direction of the buzzer pin, and the material guide piece 203 is fixed on the material guide groove 204 by a fixing clip 207, and the material guide groove The end of 204 away from the electromagnetic vibrating plate 201 is a material guide outlet, the end of the material guide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com