Cutting machine for asbestos plates

A cutting machine and asbestos board technology, applied in the direction of stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of cutting size error, low production efficiency, time-consuming and labor-intensive manual cutting, etc., to ensure the cutting length, reduce working intensity, Guaranteed consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

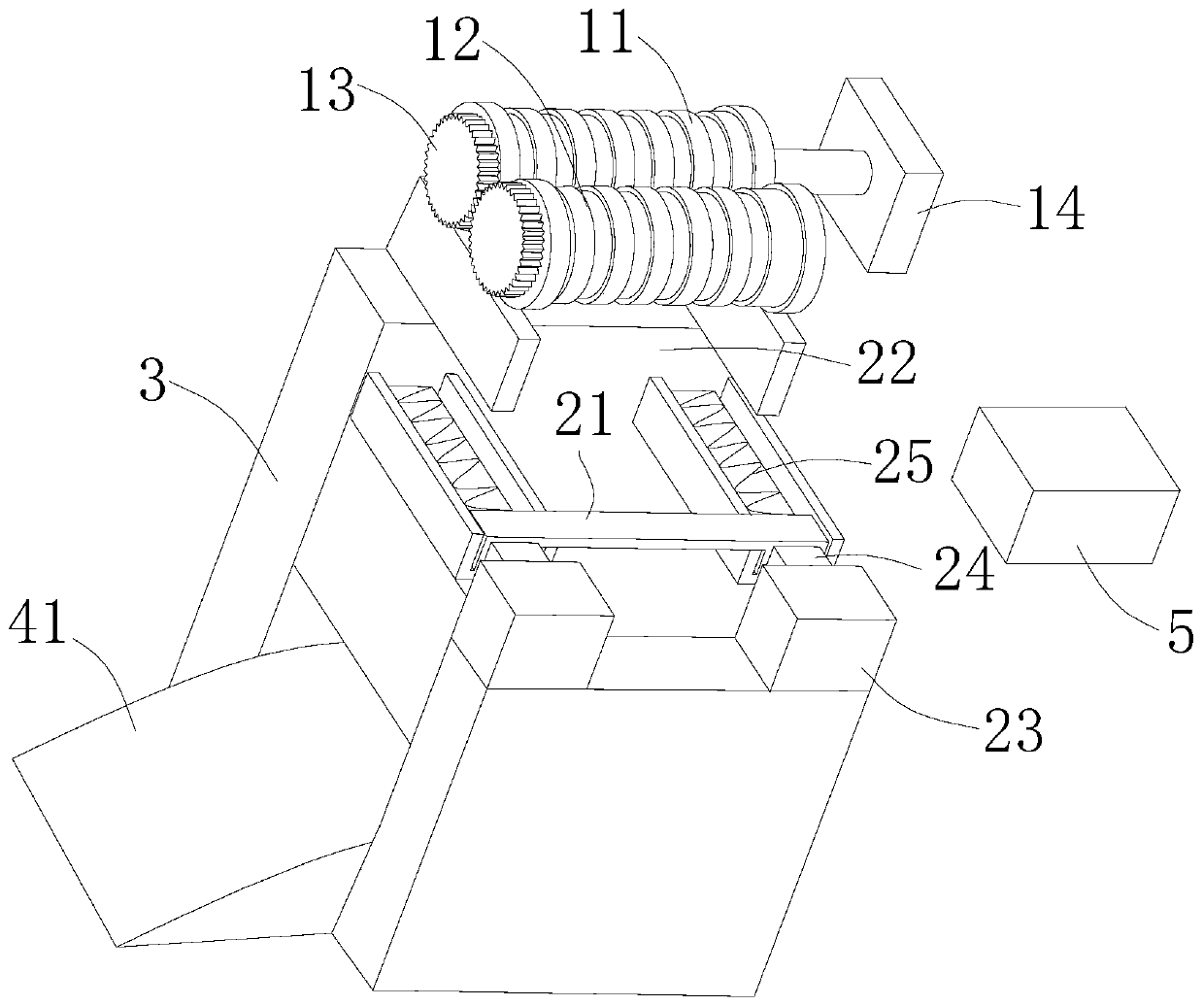

[0024] Such as Figure 1-4 As shown, the asbestos board cutting machine includes an extrusion module, a shear module, a material receiving module, a support seat 3 and a control module, the extrusion module is fixed on the support seat 3 by a fixing plate, and the shear module is arranged on Below the extruding module, the material receiving module is arranged under the shearing module, and the control module is respectively connected with the extruding module and the shearing module;

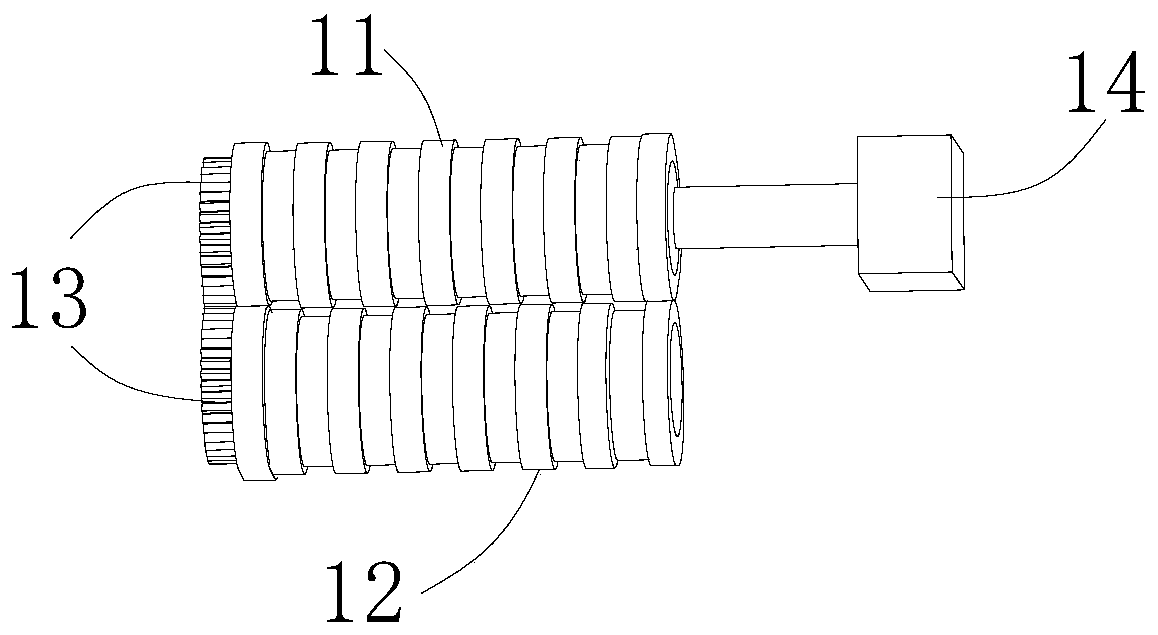

[0025] Such as figure 2 As shown, the extrusion module includes a driving roller 11 and a driven roller 12 arranged in parallel, and the driving roller 11 and the driven roller 12 are provided with several equidistant circular grooves, and the circular grooves The width of the groove is equal to the spacing between two adjacent annular grooves, the annular groove on the driving roller 11 and the annular groove on the driven roller 12 are misaligned, and the driving roller 11 and the driven ro...

Embodiment 2

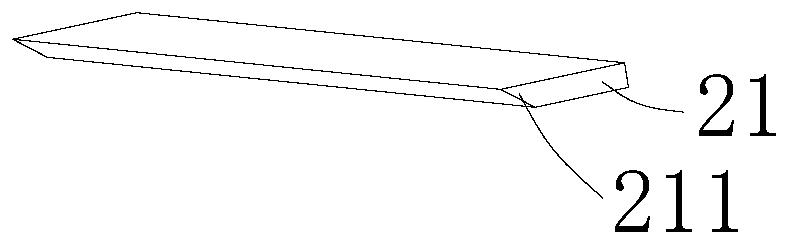

[0030] Based on the structure of Embodiment 1, in Embodiment 2, the upper end of the fixed cutting block 22 is set as a right-angled triangle, so that the asbestos slats extruded into strips by the extruding module can enter the shearing module.

Embodiment 1-2

[0031] In embodiment 1-2,

[0032] The cylinder 23 is provided with a pressure sensor, and the pressure sensor is connected with the controller 5 .

[0033] The upper end of the gap between the driving roller 11 and the driven roller 12 is a feed inlet.

[0034] The outlet of the feed inlet is located in the middle of the upper end surface of the fixed cutting block 22 .

[0035] The width of the annular groove matches the width dimension of the required asbestos board.

[0036] Working principle: The upper end of the gap between the driving roller 11 and the driven roller 12 in the present invention is the feed inlet, the asbestos board to be cut enters the extrusion module through the feed inlet, and the controller 5 controls the motor 14 to carry out Working, the motor 14 drives the driving roller 11 to rotate, through the meshing of the two working gears 13, the driving roller 11 drives the driven roller 12 to rotate in opposite directions to bite and squeeze the asbesto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com