Hot-rolled medium manganese steel with high product of strength and elongation and relatively low Mn content and preparation method thereof

A technology of high-strength plastic accumulation and medium manganese steel, which is applied in the field of automotive steel to achieve the effect of reducing Mn content and reducing the risk of embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The second aspect of the present invention provides a method for preparing the above-mentioned hot-rolled high-strength plastic medium-manganese steel with a lower Mn content, the steps comprising:

[0033] S1. Continuous casting of molten steel to produce slabs or die castings to produce ingots. The chemical composition of the molten steel includes: by weight percentage, C: 0.19-0.5%, Mn: 3.0-7.0%, Al: 1.0-3.0%, Si : 0-2.0%, Cr: 0-5.0%, Ni: 0-2.0%, the balance is Fe and unavoidable impurities;

[0034] S2. Hot rolling the billet or ingot obtained in step S1 after opening the billet. The hot rolling process includes: heating the billet to 1120-1200°C, soaking time for 1.5-2.5h, and hot rolling to a thickness through multiple passes 2-6mm thin plate, the final rolling temperature of the multi-pass hot rolling is 820-900°C, the coiling temperature after rolling is 500-600°C, and air-cooled to room temperature;

[0035] S3. Put the hot-rolled sheet or coiled sheet obtained...

Embodiment 1

[0038] This embodiment provides a hot-rolled high-strength plastic-laminated medium-manganese steel with a relatively low Mn content. The chemical composition is, by weight percentage, C: 0.45%, Mn: 6.0%, Al: 2.0%, and Si: 1.0%. , Cr: 0.7%, Ni: 0.4%, and the balance is Fe and unavoidable impurities.

[0039] The preparation method of the above-mentioned hot-rolled high-strength plastic product medium manganese steel with lower Mn content, the steps include:

[0040] The steel billet is heated to 1200°C, soaking time is about 2 hours, and hot rolled to a steel plate with a thickness of 4mm through multiple passes, the final rolling temperature is 820°C, and then coiled at 550°C and air-cooled to room temperature.

[0041] The hot-rolled steel coils were annealed in a bell-type heating furnace, kept at 700 °C for 1 h, and then cooled to room temperature.

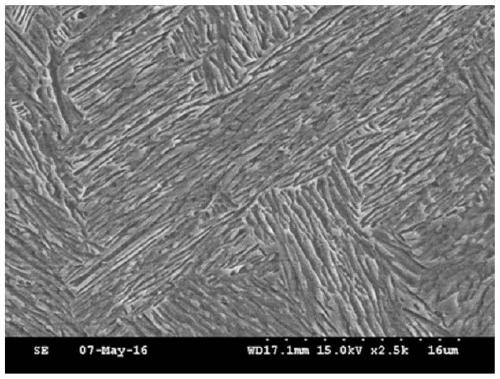

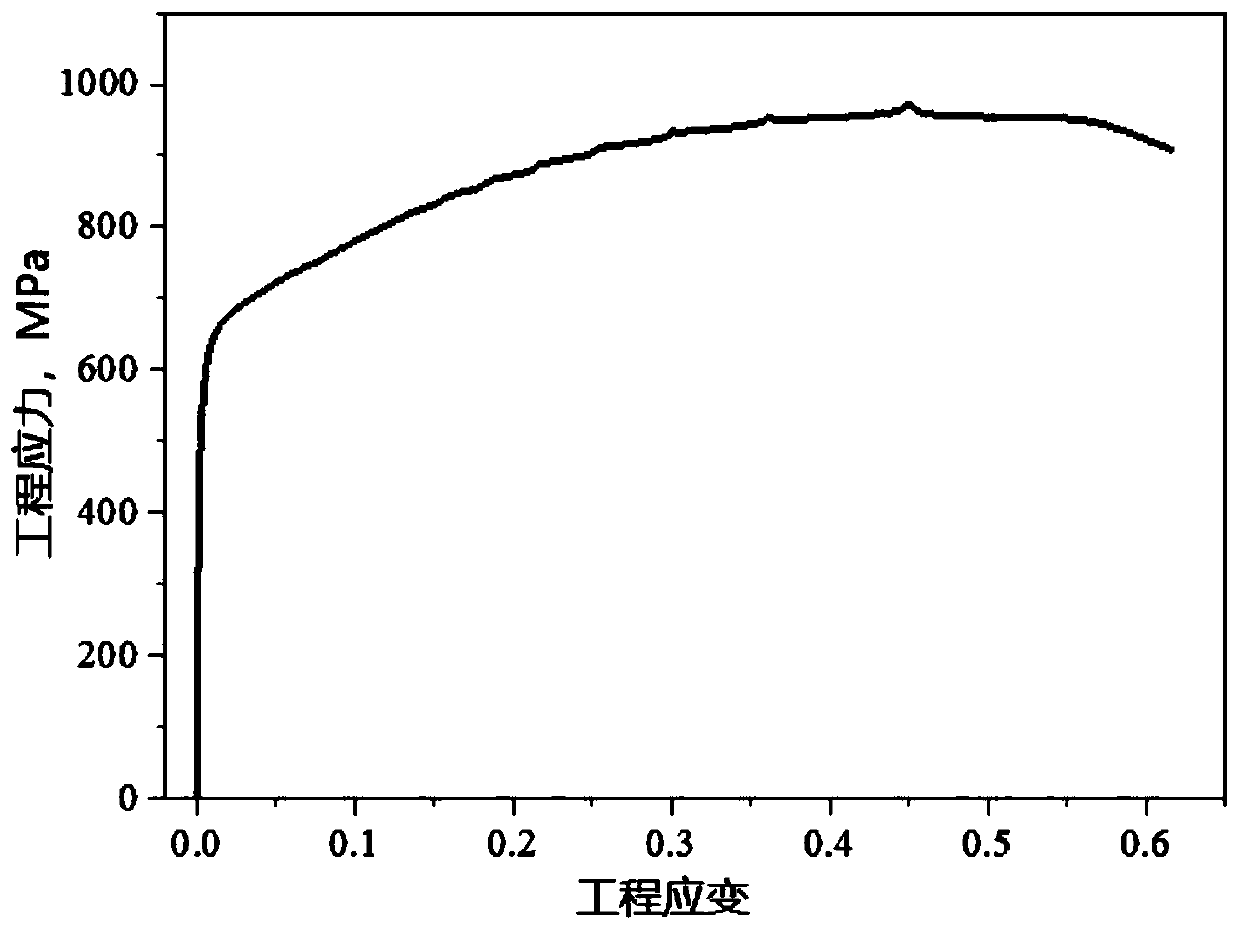

[0042] A hot-rolled high-strength plastic-laden medium-manganese steel was obtained, and its structure scanning electron mi...

Embodiment 2

[0047] This embodiment provides a hot-rolled high-strength plastic-laminated medium-manganese steel with a relatively low Mn content. The chemical composition is, by weight percentage, C: 0.38%, Mn: 3.0%, Al: 2.1%, and Si: 0.8% , Cr: 3.1%, Ni: 1.8%, V: 0.2%, B: 0.2%, and the balance is Fe and unavoidable impurities.

[0048] The preparation method of the above-mentioned hot-rolled high-strength plastic product medium manganese steel with lower Mn content, the steps include:

[0049] The steel billet is heated to 1180°C, soaking time is about 2 hours, and hot-rolled to a steel plate with a thickness of 5mm through multiple passes, the final rolling temperature is 850°C, and then coiled at 525°C and air-cooled to room temperature.

[0050] The hot-rolled steel coil was put into a bell-type heating furnace for annealing, kept at 670° C. for 3 hours, and then cooled to room temperature to obtain a hot-rolled high-strength plastic-laminated medium-manganese steel whose mechanical p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com