Heat energy recovery system

A heat energy recovery and heat energy technology, applied in heat recovery systems, energy recovery systems for ventilation and heating, air conditioning systems, etc. The effect of reducing energy loss and avoiding excessive cotton dust particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

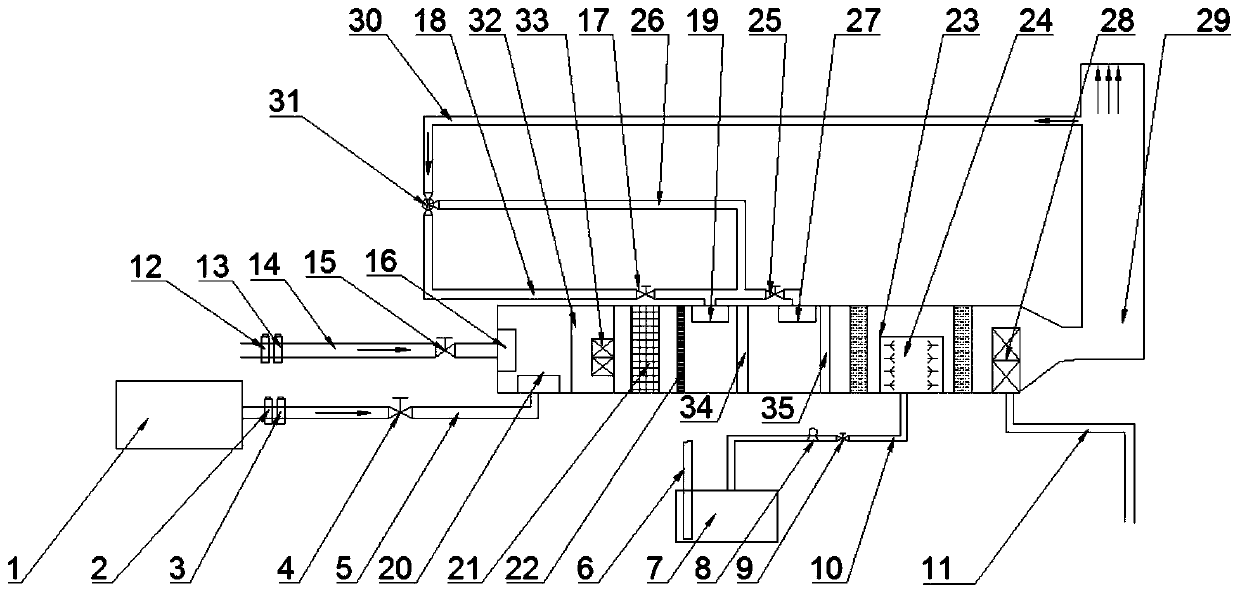

[0031] A heat energy recovery system, including a fresh air system, a return air system, a dust removal heat recovery system, a filter system and an air conditioning system; the five systems are connected through an air volume regulating valve and passages, and the air volume of the fresh air system, the return air system, and the dust removal heat energy are recovered The air volume of the system, the wind energy is mixed and preheated by the fresh air system and the dust removal heat energy recovery system, then enters the filter system for filtration, and after filtration, it is mixed with the wind energy of the return air system and enters the air conditioning system. The return air system sends all the way to the room to complete cooling or heating.

[0032] Further, the fresh air system includes a fresh air humidity tester 12, a fresh air temperature tester 13, and a fresh air window air volume regulating valve 15. The fresh air system performs humidity and temperature test...

Embodiment 2

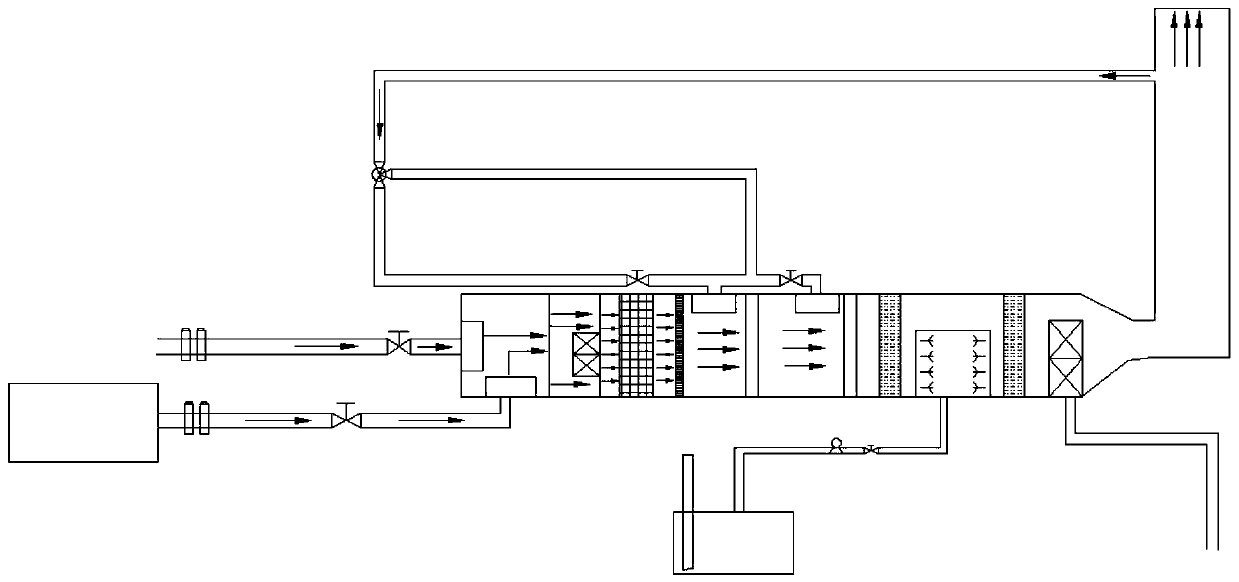

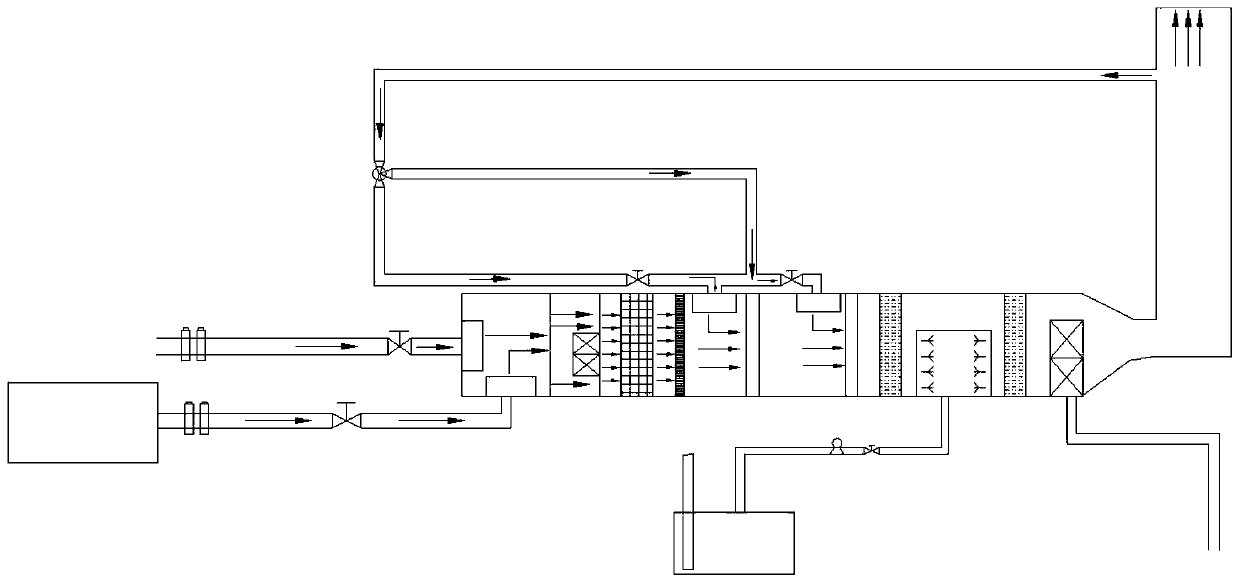

[0042] figure 2 It is a schematic diagram of the flow of heat energy recovered from dust removal heat energy in the present invention, figure 2 The fresh air wind energy in the central fresh air system is tested and analyzed by the fresh air humidity tester 12 and the fresh air temperature tester 13, and the air volume is adjusted by adjusting the fresh air window air volume regulating valve 15 and enters the fresh air window 16 through the fresh air pipe 14; the dust removal unit 1 performs dust removal operation Finally, the thermal energy after dedusting is tested and analyzed by the dedusting thermal energy temperature tester 2 and the dedusting thermal energy humidity tester 3, and the dedusting thermal energy air volume control valve 4 is adjusted through the dedusting wind energy pipeline 5 to enter the dedusting thermal energy return wind window 20; 16 and the dust removal heat energy return window 20 heat energy enters the mixing preheating chamber 32, and the fresh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap