A centroid detection device and method

A detection device and detection method technology, applied in the direction of measuring device, machine/structural component test, static/dynamic balance test, etc., can solve the problems of low precision, difficult to eliminate processing error and operation error, complicated operation, etc., to achieve The effect of reducing the introduction of error and improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

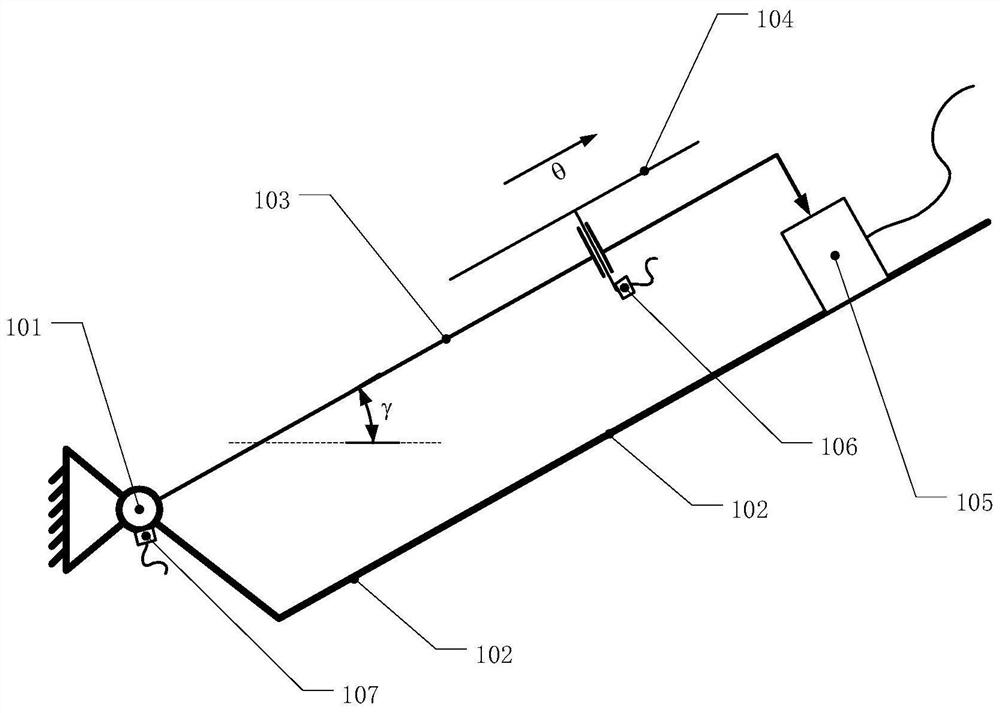

[0044] A centroid testing device such as figure 1 As shown, it includes a turntable 104, a turntable angle sensor 106, and a support mechanism, and the support mechanism includes: a force plate 103, a load cell 105, a support plate 102, a support hinge 101 and a force plate angle sensor 107;

[0045] The rotation axis of the turntable 104 is vertically arranged in the force plate 103, and the force plate 103 is used to support the turntable 104, and the rotation axis is provided with a device for reading the angle θ of the turntable 104. A turntable angle sensor 106; the turntable 104 is used to fix the test object.

[0046] The force plate 103 and the support plate 102 are arranged in parallel, and the load cell 105 is arranged between the two. The test direction of the force sensor 105 is parallel to the normal direction of the force plate 103, and is used to measure the load cell 105. The normal phase pressure F of the force plate 103 on the support plate 102 .

[0047] T...

Embodiment 2

[0049] Utilize the centroid test device that embodiment 1 provides to carry out centroid test step as follows:

[0050] (1) Make the supporting surface of the object to be measured in the γ-plane at an angle to the horizontal plane, where 0°<γ<90°; details are as follows:

[0051] The object to be tested is fixed on the rotating disc of the centroid testing device provided in Embodiment 1. In the initial state, the force plate 103 is at a horizontal position or at any position with a known inclination angle. Drive the support plate 102 to rotate along the hinge 101 until the reading of the force plate angle sensor is 0°<γ<90°.

[0052] (2) using the coordinates of the center of mass of the object to be measured as a parameter, establishing a mathematical relationship between it and the normal pressure on the support surface;

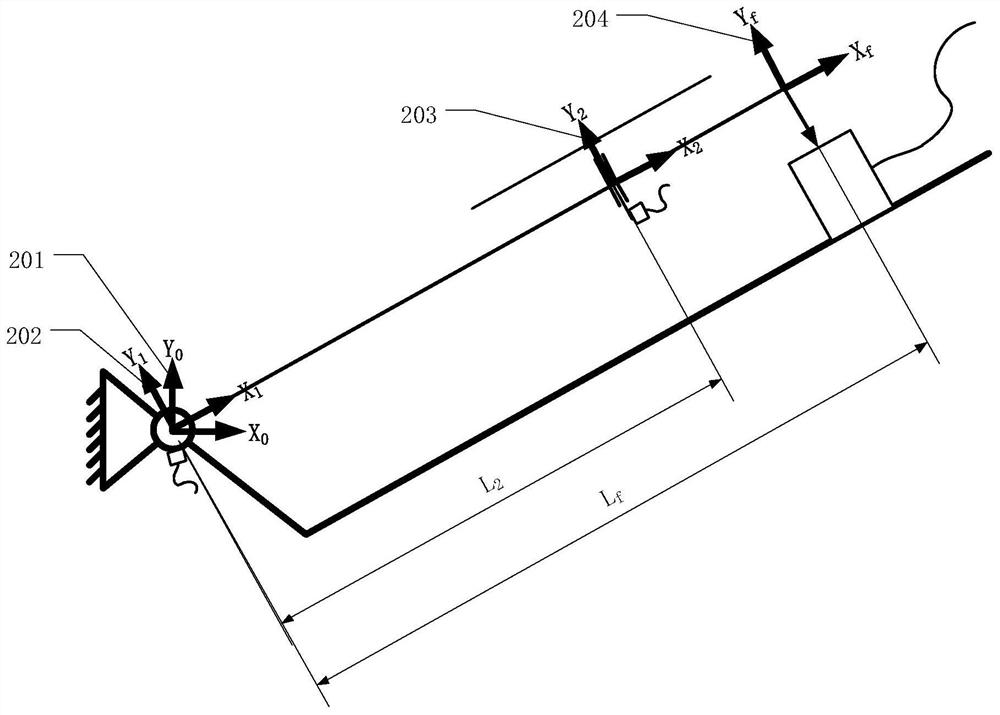

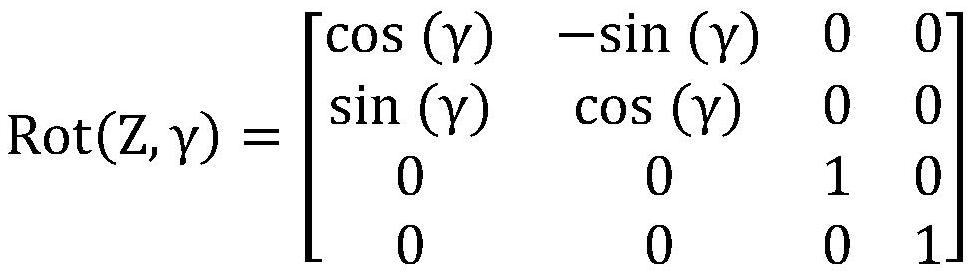

[0053] according to figure 2 Establish the mechanism coordinate system. It is required that the origins of all coordinate systems be arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com