Memory, refining process flow segmented simulation and optimization method, device and equipment

A simulation method and refining technology, applied in design optimization/simulation, instrumentation, chemical statistics, etc., can solve problems such as poor accuracy, error, difficult molecular weight, etc., to improve accuracy, reduce error-introducing links, and avoid errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

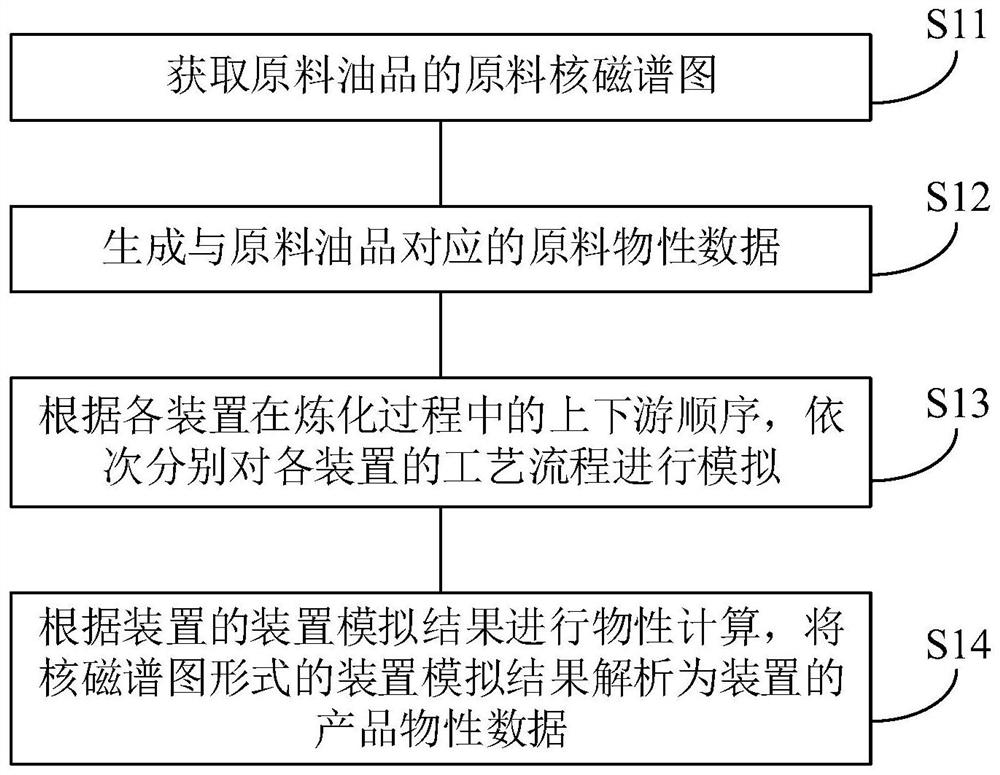

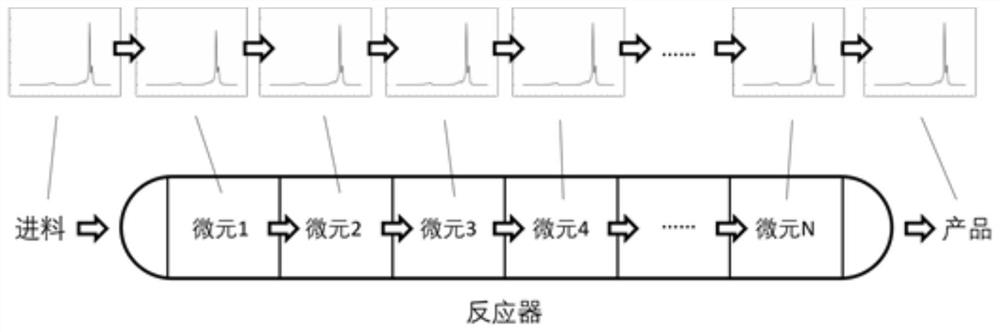

[0073] In order to improve the accuracy of the results when simulating the refining process, such as figure 1 As shown, in the embodiment of the present invention, a refining and chemical process flow segmentation simulation method is provided, including steps:

[0074] S11. Obtain the raw material nuclear magnetic spectrum of the raw oil product;

[0075] In the embodiment of the present invention, nuclear magnetic resonance technology is first used to generate a corresponding nuclear magnetic spectrum according to the raw oil product. In the embodiment of the present invention, the nuclear magnetic spectrum generated according to the raw material oil may be referred to as a raw material nuclear magnetic spectrum. The raw oil product in the embodiment of the present invention refers to the refining feed, such as mixed crude oil, naphtha or gasoline and diesel oil.

[0076] In practical applications, the data required for segmental simulation of the refining process also inc...

example 1

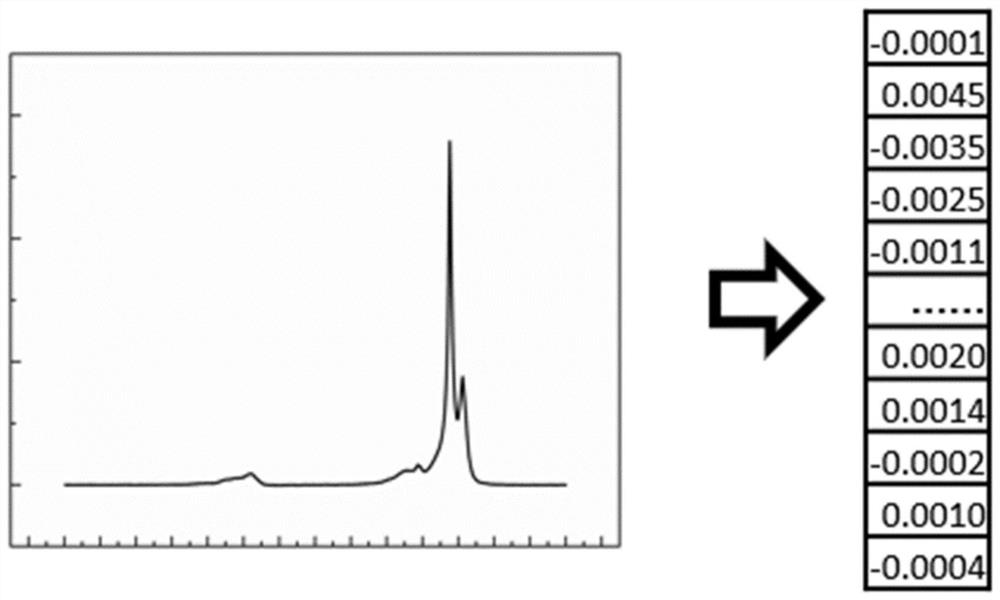

[0107] The raw material properties and product distribution of Example 1 are shown in Table 1; the nuclear magnetic spectrum data of raw material oil and product oil are shown in figure 2 ;

[0108] Table 1

[0109]

[0110] The simulation results (product oil simulation results) in the form of NMR spectra calculated according to the subsection simulation method of the refining process flow in the embodiment of the present invention are as follows: Figure 5 Shown; According to the simulation result analysis of this nuclear magnetic spectrogram form, the product physical property data that generates is as shown in table 2;

[0111] Table 2:

[0112]

[0113] The above is the specific simulation result obtained in an example (Example 1) and the error value of the simulation result according to the segmental simulation method of the refinery process flow in the embodiment of the present invention.

[0114] As a comparison, the same application scenario of the full-proc...

Embodiment 2

[0120] On the other side of the embodiment of the present invention, there is also provided a refinery process segment simulation device, Figure 6 It shows a schematic structural diagram of the refinery process flow segmentation simulation device provided by the embodiment of the present invention, and the refinery process flow segmentation simulation device is the same as figure 1 The device corresponding to the segmental simulation method of the refinery process flow described in the corresponding embodiment, that is, realized by means of a virtual device figure 1 In the corresponding embodiment of the refinery process flow segment simulation method, each virtual module constituting the refinery process flow segment simulation device can be executed by electronic equipment, such as network equipment, terminal equipment, or server. Specifically, the refining and chemical process flow segmentation simulation device in the embodiment of the present invention includes:

[0121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com