Refractory wash bonding time tester and testing method

A technology of time tester and refractory mud, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of large influence on test results, torsional slip dislocation, poor precision, etc., and achieve simple test methods and accurate test results high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

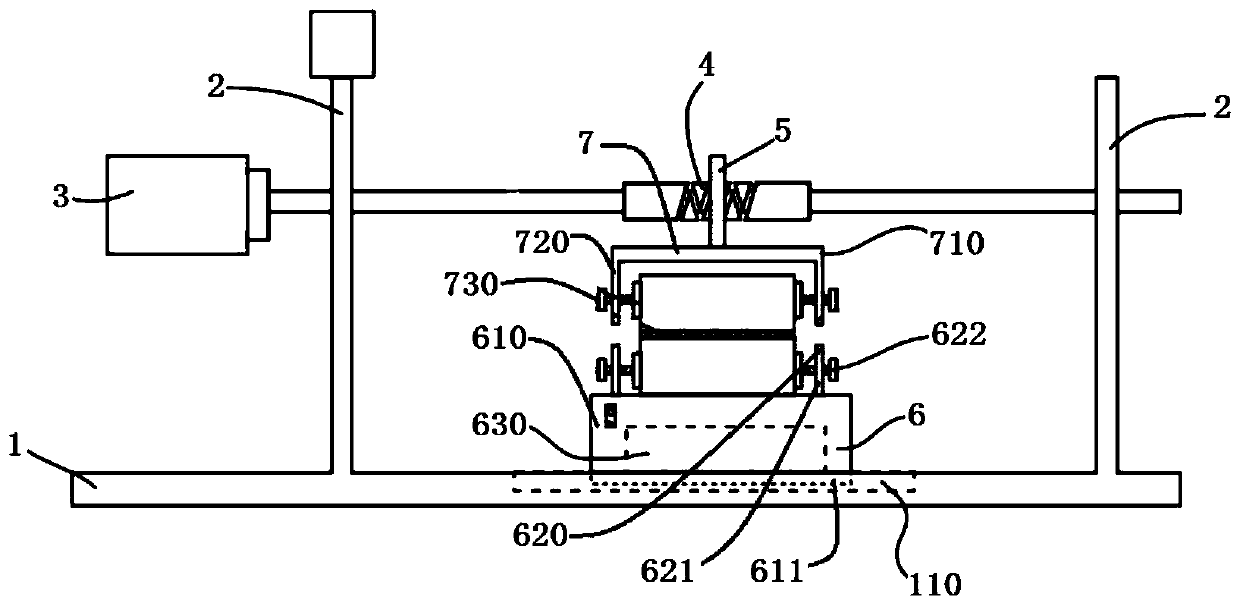

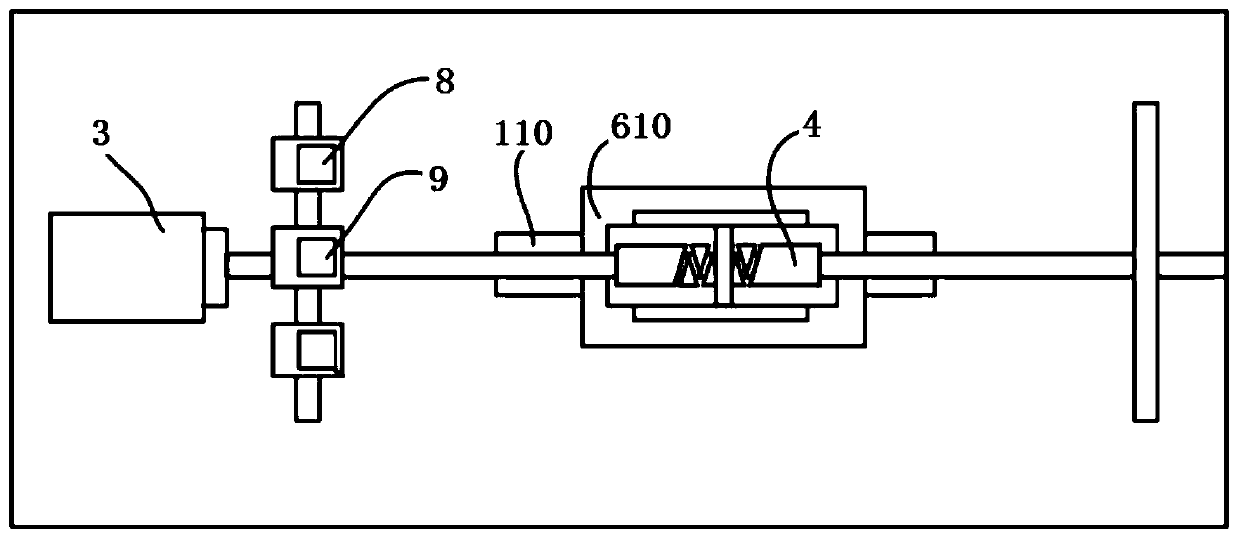

[0029] Such as figure 1 , figure 2 As shown, a refractory mud bonding time tester includes a base plate 1, a support frame 2, a servo motor 3, a reciprocating screw rod 4, a slider 5, a bearing seat 6, a mechanical claw 7, a force measuring device 8 and a timer 9 . Bearing seat 6 is arranged on the upper end face of base plate 1, and base plate 1 is respectively provided with a supporting frame 2 on both sides of bearing seat 6, and the two ends of reciprocating screw rod 4 are respectively connected with two supporting frames 2 in rotation, and reciprocating screw rod 4. It is preferably located directly above the bearing seat 6. The servo motor 3 is arranged on the support frame 2 or the bottom plate 1. The output shaft of the servo motor 3 is connected with one end of the reciprocating screw rod 4, that is, the servo motor 3 can drive the reciprocating The screw mandrel 4 rotates; the reciprocating screw mandrel 4 between the two support frames 2 is provided with a slide...

Embodiment 2

[0031] Such as figure 1 , figure 2 As shown, a refractory mud bonding time tester includes a base plate 1, a support frame 2, a servo motor 3, a reciprocating screw rod 4, a slider 5, a bearing seat 6, a mechanical claw 7, a force measuring device 8 and a timer 9 . Bearing seat 6 is arranged on the upper end face of base plate 1, and base plate 1 is respectively provided with a supporting frame 2 on both sides of bearing seat 6, and the two ends of reciprocating screw rod 4 are respectively connected with two supporting frames 2 in rotation, and reciprocating screw rod 4. It is preferably located directly above the bearing seat 6. The servo motor 3 is arranged on the support frame 2 or the bottom plate 1. The output shaft of the servo motor 3 is connected with one end of the reciprocating screw rod 4, that is, the servo motor 3 can drive the reciprocating The screw mandrel 4 rotates; the reciprocating screw mandrel 4 between the two support frames 2 is provided with a slide...

Embodiment 3

[0034] Such as figure 1 , figure 2 As shown, a refractory mud bonding time tester includes a base plate 1, a support frame 2, a servo motor 3, a reciprocating screw rod 4, a slider 5, a bearing seat 6, a mechanical claw 7, a force measuring device 8 and a timer 9 . Bearing seat 6 is arranged on the upper end face of base plate 1, and base plate 1 is respectively provided with a supporting frame 2 on both sides of bearing seat 6, and the two ends of reciprocating screw rod 4 are respectively connected with two supporting frames 2 in rotation, and reciprocating screw rod 4. It is preferably located directly above the bearing seat 6. The servo motor 3 is arranged on the support frame 2 or the bottom plate 1. The output shaft of the servo motor 3 is connected with one end of the reciprocating screw rod 4, that is, the servo motor 3 can drive the reciprocating The screw mandrel 4 rotates; the reciprocating screw mandrel 4 between the two support frames 2 is provided with a slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com