Winding coil inspection method, device, cooking appliance and readable storage medium

A technology of a winding coil and an inspection method, which is applied in the fields of computer readable storage medium and cooking utensil detection, and can solve the problems of open circuit, fuse of the winding coil, temperature rise of the winding coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

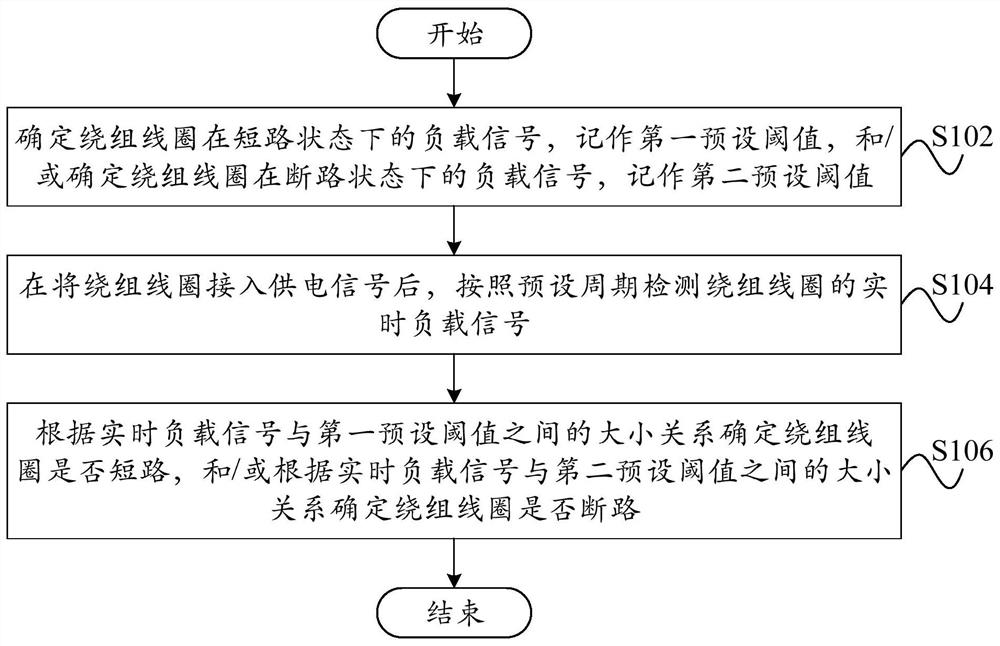

Embodiment 1

[0098] Figure 4 A schematic block diagram of a winding coil inspection system according to an embodiment of the present invention is shown.

[0099] like Figure 4 As shown, the winding coil inspection system according to an embodiment of the present invention includes: an input end 402 for inputting a PWM wave signal to the solenoid valve driving module 404; the solenoid valve driving module 404, whose input interface is connected to the input end 402, It is used to adjust any driving voltage signal required by the output solenoid valve 408; the output end 406 is connected to the output interface of the solenoid valve driving module 404, and is used to output the driving voltage signal to the solenoid valve 408; the solenoid valve 408 is connected to the output end 406 , which is used to adjust the opening and closing degree according to the driving voltage signal generated by the solenoid valve driving module 404; the output terminal feedback voltage A / D acquisition circui...

Embodiment 2

[0105] Figure 5 A schematic flow chart of a winding coil inspection method according to another embodiment of the present invention is shown.

[0106] like Figure 5 As shown, the winding coil inspection method according to another embodiment of the present invention includes: step S502, power on and initialize the microcontroller MCU; step S504, the microcontroller MCU starts the timer T, and within the timing period t, The input end of the solenoid valve drive module keeps sending PWM waves with a certain frequency and duty cycle; step S506, the feedback loop of the drive module samples n output end feedback voltage A / D values at regular intervals within the timing period t; step S508, judges Whether the timing reaches the timing period t, if so, go to step S510, if not, go to step S506; step S510, turn off the PWM wave at the input end, and average the sampled n feedback voltage A / D values to obtain the final sampled D value In step S512, the D value is compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com