Two-component solventless adhesive compositions

An adhesive and solvent-free technology, applied in the direction of non-polymer adhesive additives, adhesive additives, adhesives, etc., can solve problems such as adhesive coating technology problems, achieve fast curing speed, improve performance, and improve method efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

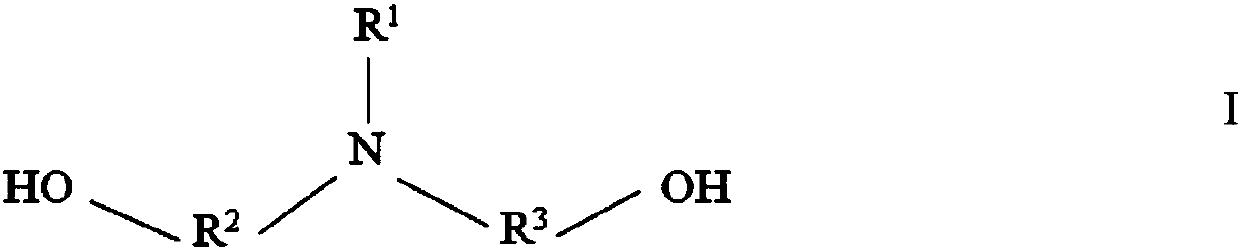

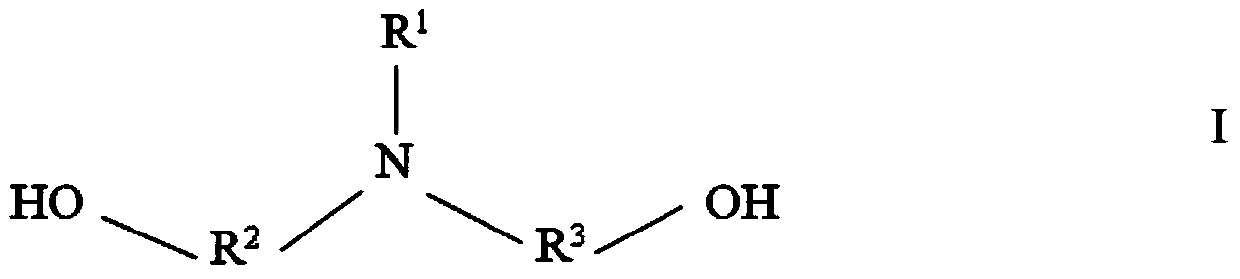

Method used

Image

Examples

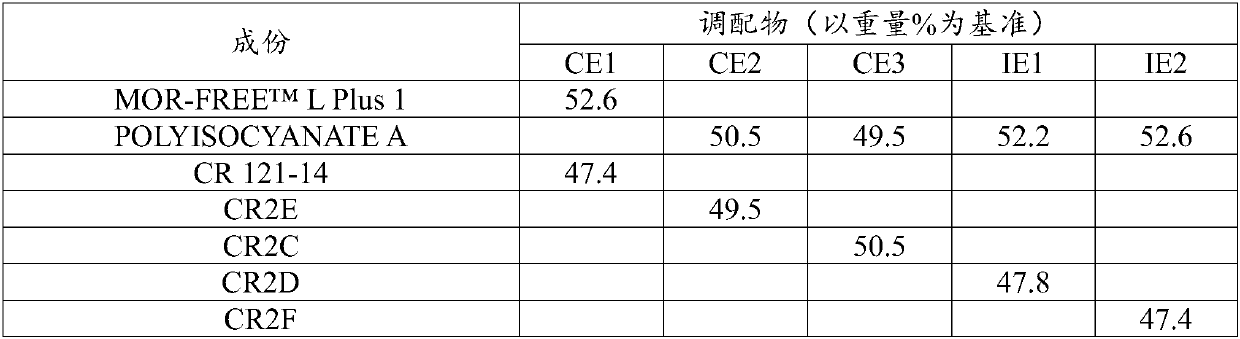

example 1

[0056] Illustrative Example 1 ("IE1")

[0057] Table 3: Composition of CR2D

[0058]

[0059]

[0060] Make VORANOL at 80°C under a nitrogen purge TM CP 450, VORANOL TM CP755 and ISONATE TM 125M was reacted in the reactor for 2 hours to form OH terminated polyether polyurethane. Synthetic polyether polyurethane with SPECFLEX TM ACTIV 2306 and MOR-FREE TM 88-138 blend to form co-reactant 2D ("CR2D"). The detailed composition information of CR2D is listed in Table 3.

[0061] A polyurethane adhesive comprising approximately 52.2% by weight polyisocyanate A and 47.8% by weight CR 2D was used to bond foil / polyethylene ("PE") structures and polyethylene terephthalate ("PET") / PE structure. The prepared laminates were cured at 25°C and 50% relative humidity. The prepared laminate samples were cut into 15mm wide strips and their T-peel adhesive strength was evaluated on a Thwing-Albert Peel Tester at 4 inches / minute. If one of the substrates elongates or tears, re...

example 2

[0063] Illustrative Example 2 ("IE2")

[0064] Table 4: Composition of CR2F

[0065] Material Percentage (weight%) VORANOL TM CP755

52.7 VORANOL TM CP450

9 ISONATE TM 125M

9.3 SPECFLEX TM ACTIV 2306

17 MOR-FREE TM 88-138

12

[0066] Make VORANOL at 80°C under a nitrogen purge TM CP 755 and ISONATE TM 125M was reacted in the reactor for 2 hours to form OH terminated polyether polyurethane. Synthetic polyether polyurethane with VORANOL TM CP450, SPECFLEX TM ACTIV 2306 and MOR-FREE TM 88-138 blend to form CR2F. The detailed composition information of CR 2F is listed in Table 4.

[0067] A polyurethane adhesive comprising about 52.6% by weight polyisocyanate A and 47.4% by weight CR2F was used to bond the foil / PE structure and the PET / PE structure. The prepared laminates were cured at 25°C and 50% relative humidity. Laminate samples were cut into 15mm wide strips and evaluated for their T-peel adhesion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap