Axial ultrasonic transducer

An ultrasonic transducer, axial technology, applied in the direction of fluid using vibration, can solve the problems of uneven preload, unstable working performance of piezoelectric ceramics, easy cracking and failure, etc., to improve mechanical strength, improve practical Application value, the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

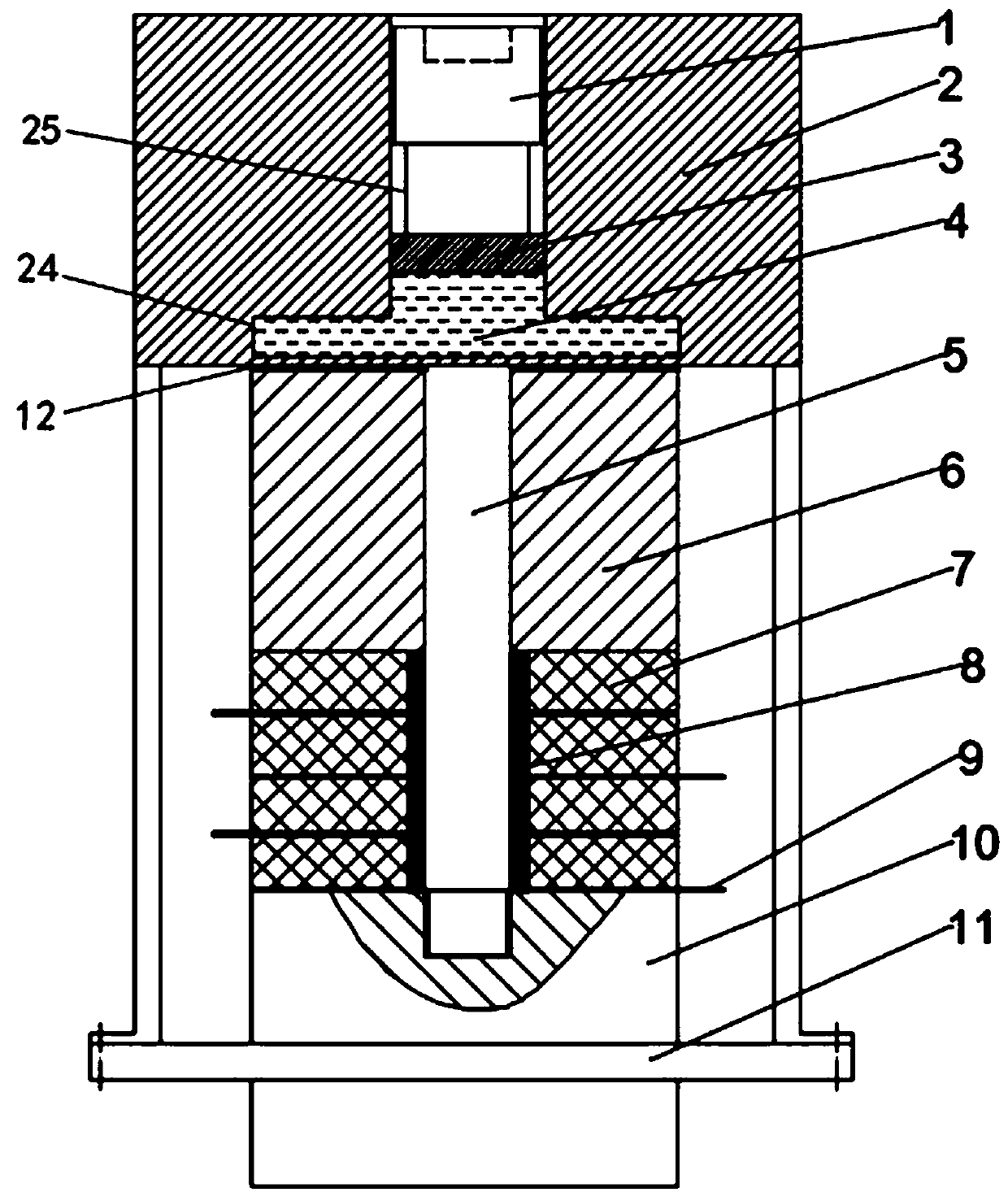

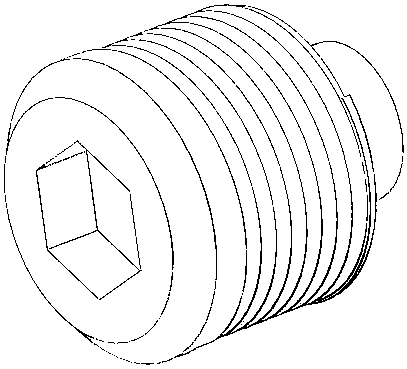

[0023] An axial ultrasonic transducer, including adjusting screw 1, pressurized body 2, sealing sliding column 3, packaging oil 4, center rod 5, upper cover plate 6, axial piezoelectric ceramic ring 7, insulating sleeve 8, copper Electrode piece 9 , lower cover plate 10 , pitch circle flange 11 , vibration isolation ring 12 .

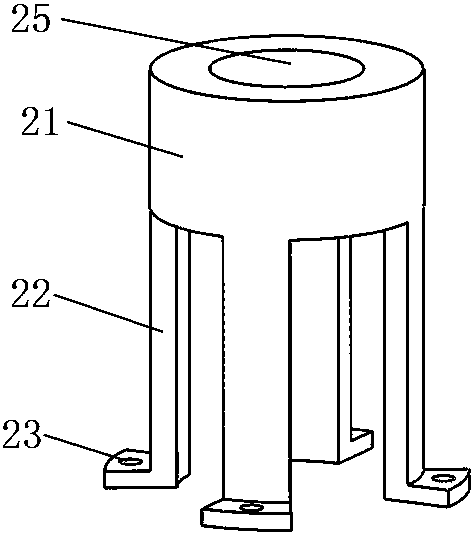

[0024] Such as figure 2 As shown, the pressurizing body 2 is composed of a pressurizing part 21 and four connecting arms 22 uniformly arranged on the bottom surface of the pressurizing part 21. The four connecting arms 22 are located on the same circumference of the outermost edge of the bottom surface of the pressurizing part 21. The end of each connecting arm 22 is provided with a flange connection end 23, and the center of the inner bottom of the pressurizing part 21 is provided with a flat inner cavity 24. mm, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com