Light part sorting equipment

A kind of parts and equipment technology, applied in the field of light parts sorting equipment, can solve the problems of large working noise, poor flexibility, limited application range, etc., and achieve the effect of low operation cost, high efficiency and accuracy, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

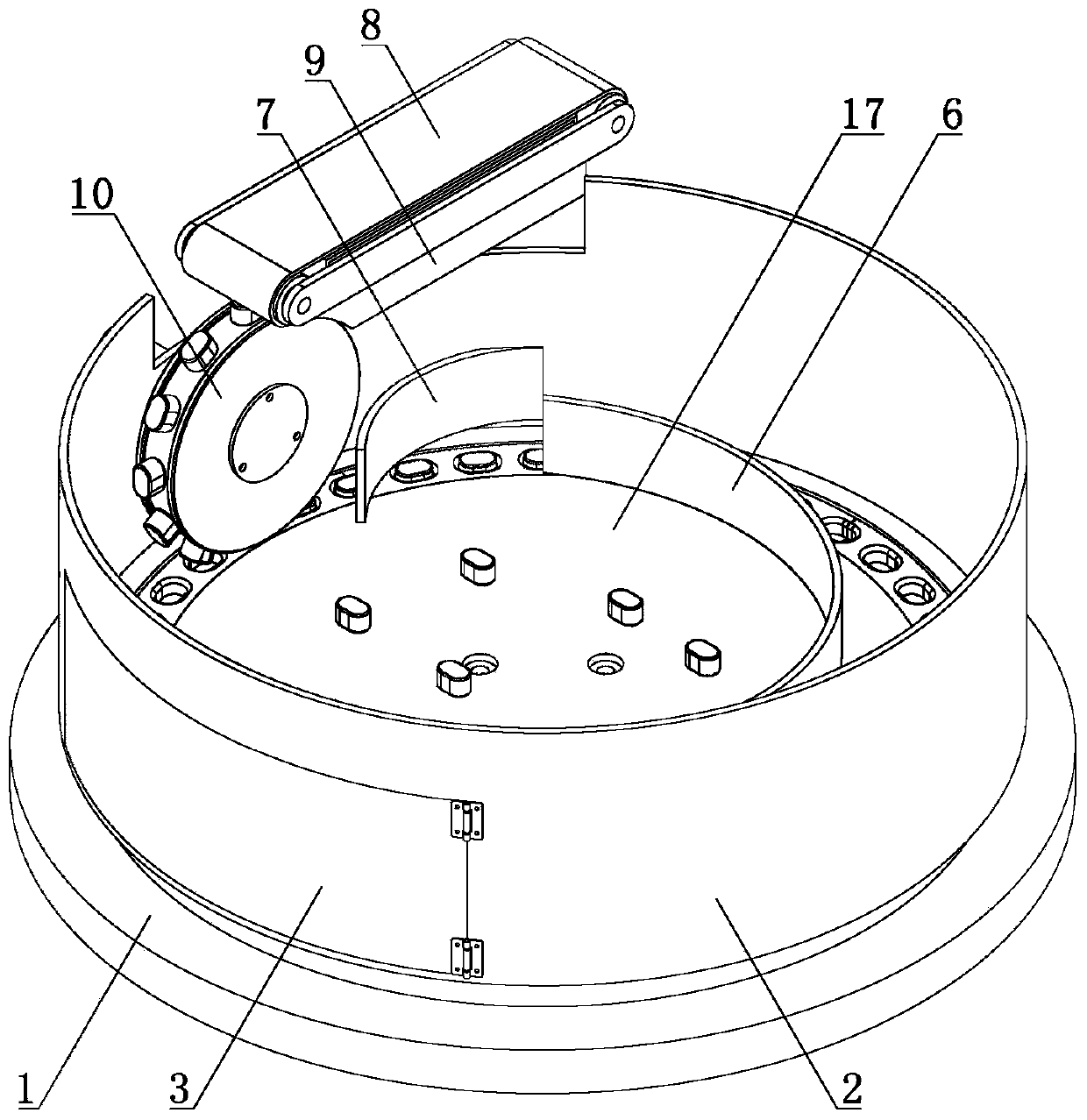

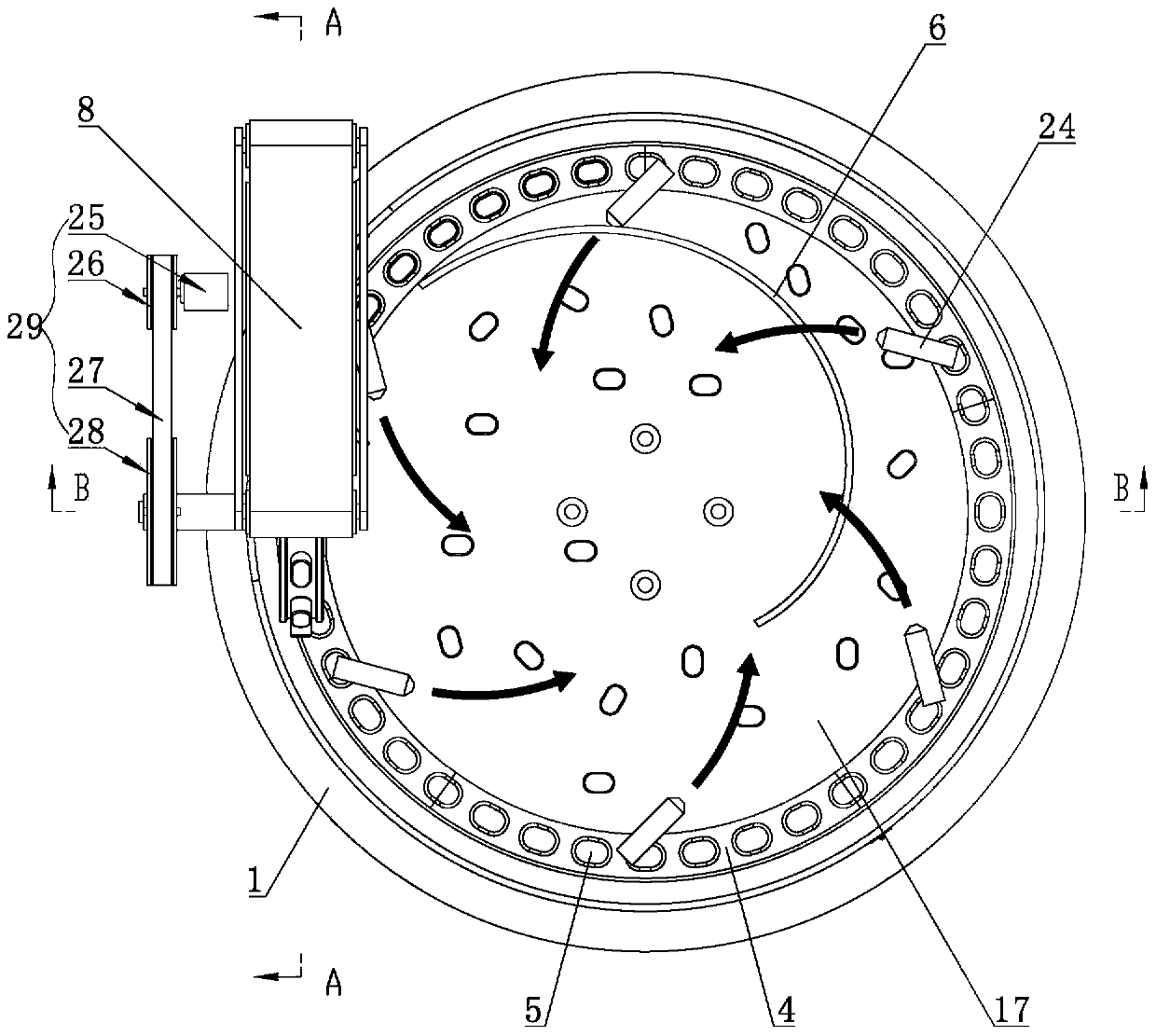

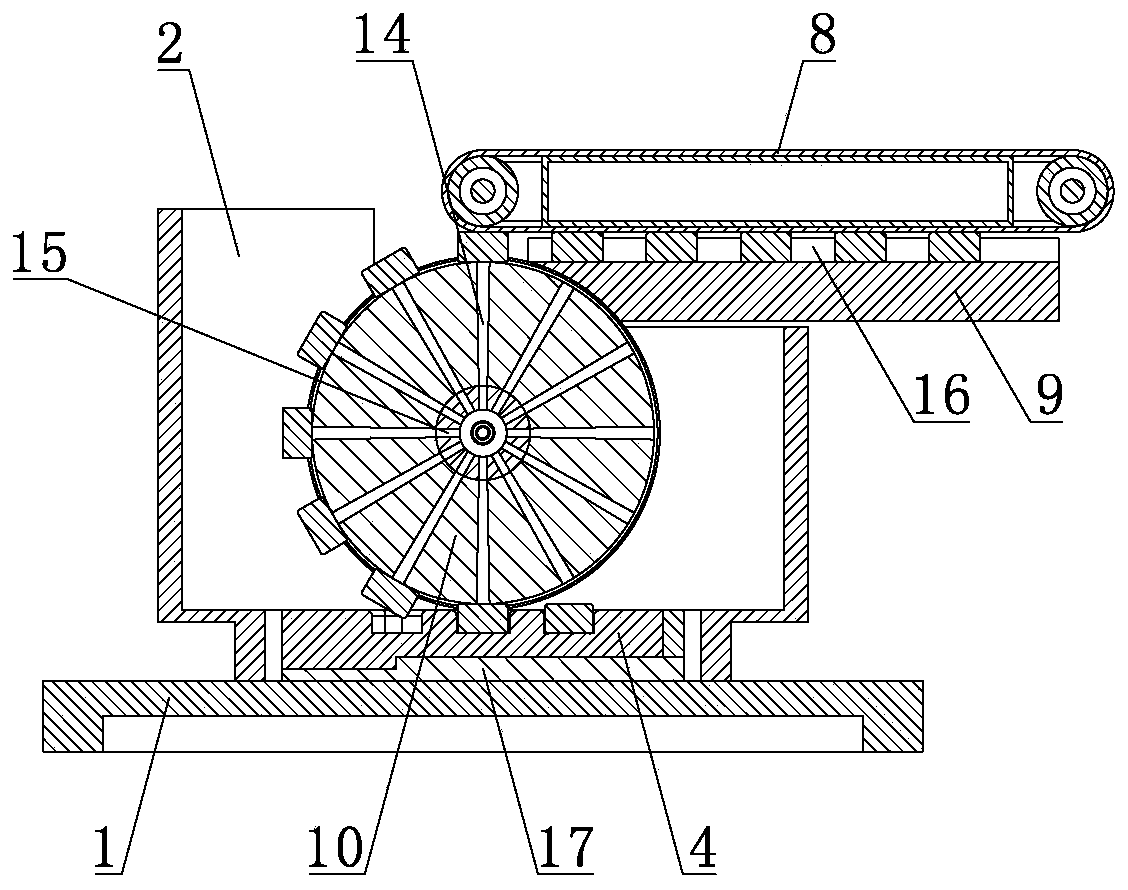

[0020] Such as Figures 1 to 4 As shown, a light-weight parts sorting device includes a machine platform 1. The machine platform 1 is provided with a turntable 17 that rotates around a vertical axis and a circle of hoardings 2 arranged on the outer periphery of the turntable 17. The turntable 17 Driven by a driving device-11, a number of detachable arc-shaped blocks 4 are arranged on the turntable-17, and the arc-shaped blocks 4 are uniformly distributed along the circumferential direction and the top surface thereof is provided with receiving grooves 5 uniformly distributed along the circumferential direction; There is a turntable 10 rotating around a horizontal axis, and the turntable 10 is d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap