Remote control device for adjusting current knob of welding equipment and application method of remote control device

A technology for welding equipment and remote control devices, applied in the field of adjustment devices, can solve the problems of insecurity, low reliability, inconvenient operation, etc., and achieve the effects of improving application efficiency and real-time control, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

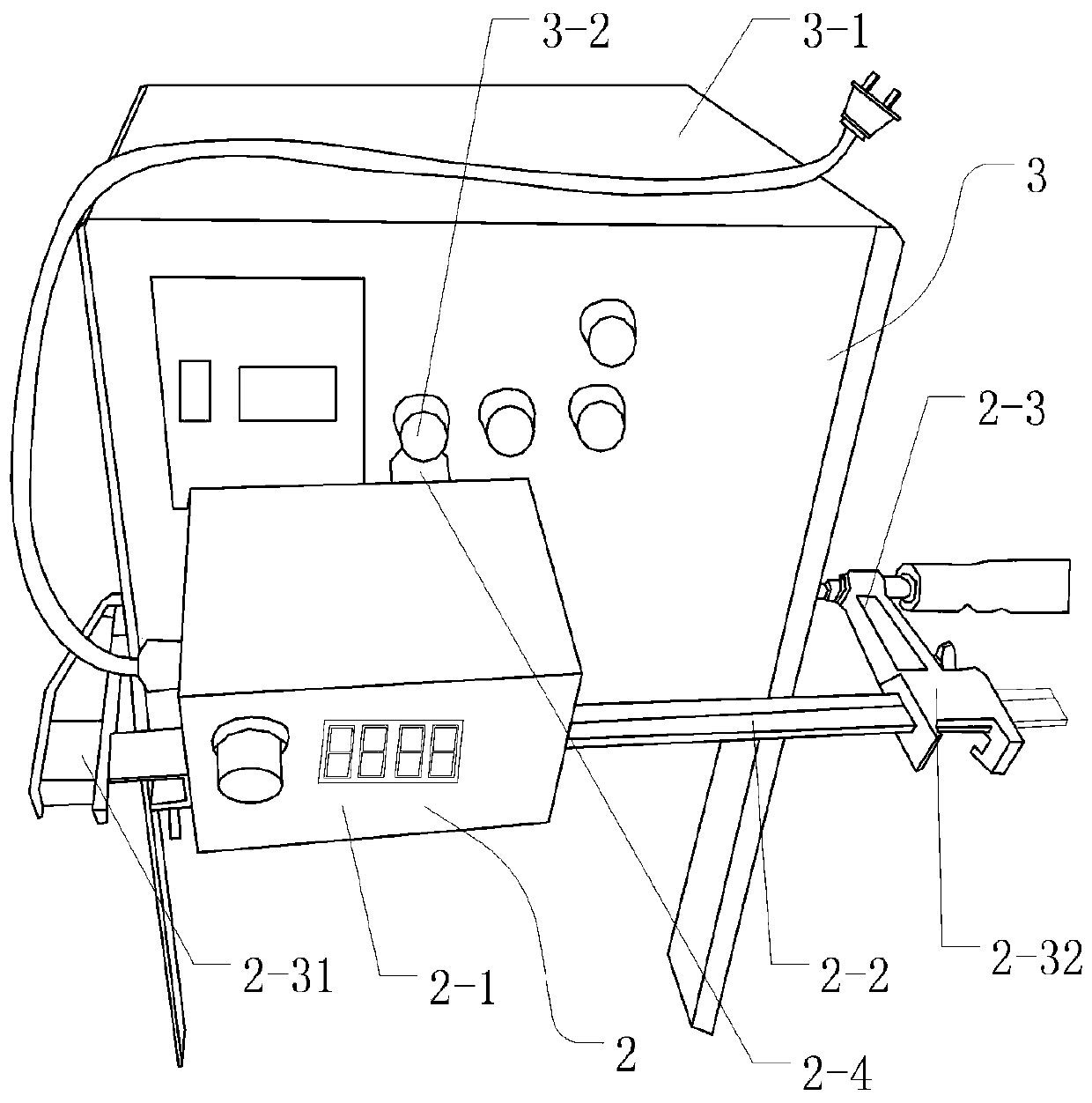

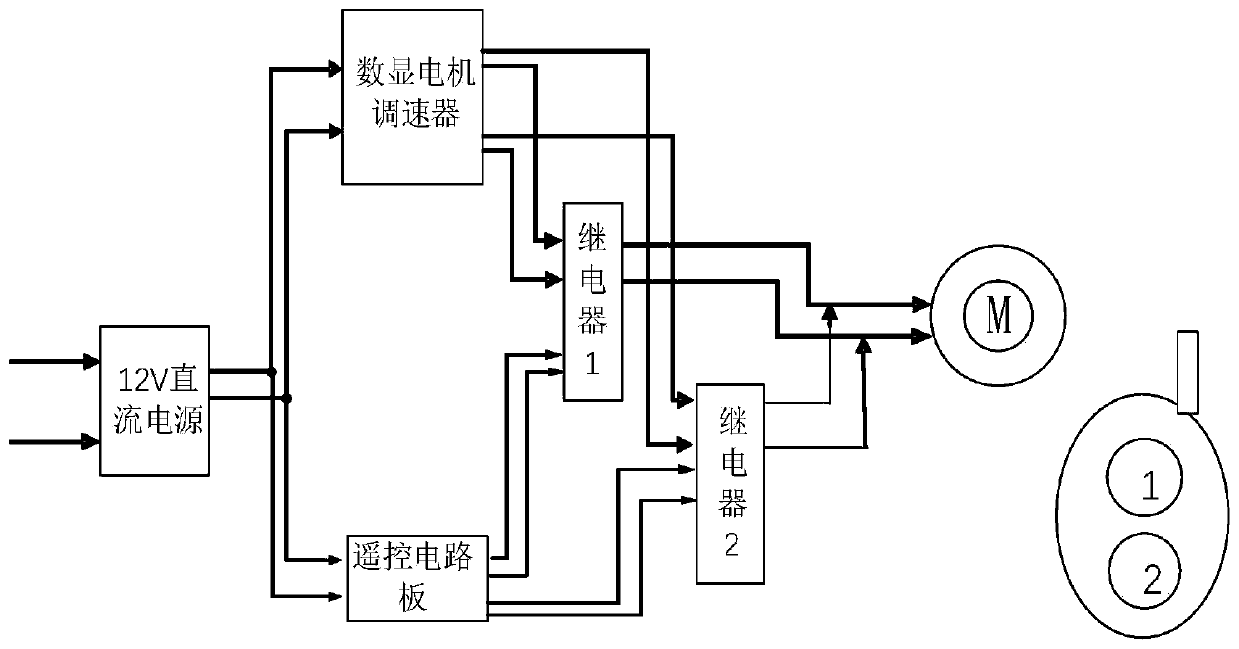

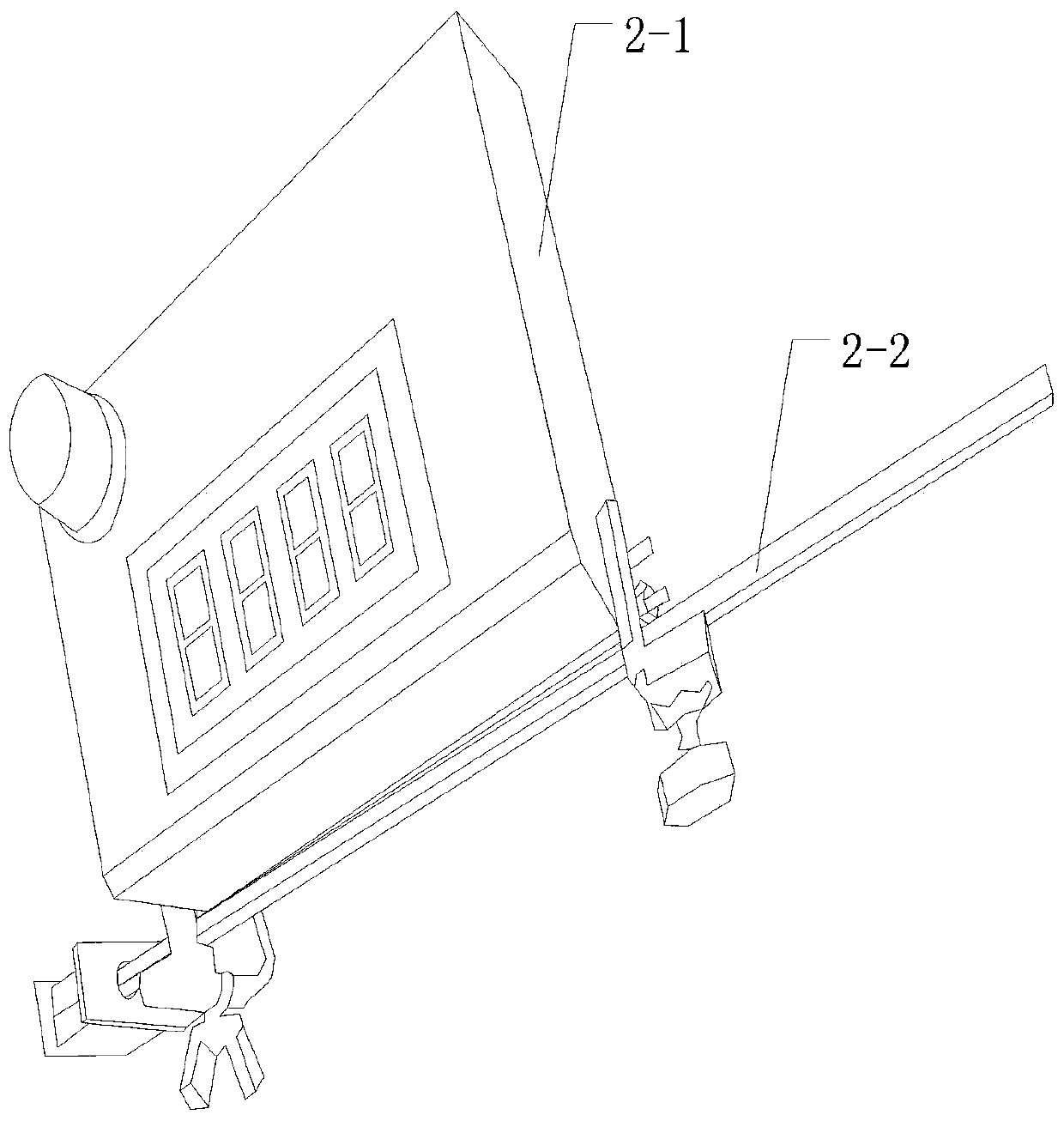

[0024] combine figure 1 , figure 2 and image 3 Describe this embodiment. In this embodiment, a remote control device for adjusting the current knob of welding equipment involved in this embodiment includes a remote controller and a control box 2. The control box 2 passes through the clamping structure 2- 3 Installed on the chassis 3-1 of the welding equipment 3, the control box 2 includes a control box shell 2-1 and a control module placed in the shell, the control module includes a DC motor, a DC motor governor, and a remote control circuit board , No. 1 relay, No. 2 relay and power supply, the input end of described DC motor governor and remote control circuit board is connected with the output end of power supply, the input end of described No. 1 relay and No. 2 relay are all connected with DC motor speed regulation The output end of the relay is connected, the input ends of the No. 1 relay and the No. 2 relay are connected with the output end of the remote control circ...

Embodiment 2

[0031] This embodiment is described in conjunction with Embodiment 1. In this embodiment, a kind of adjustment method based on the remote control device for adjusting the current knob of welding equipment involved in this embodiment includes the following steps:

[0032]Step 1. Fix the control box 2 on the chassis 3-1 of the pre-controlled welding equipment 3 through the clamping structure 2-3; fix the remote controller on the handheld device through the fixing shell 1-3;

[0033] Step 2, adjust the relative position of the control box 2 and the support rod 2-2, so that the executive end of the DC motor extending out of the control box housing 2-1 contacts the pre-control knob 3-2;

[0034] Step 3. Adjust the DC motor governor according to the sensitivity of the current knob to control the rotation speed of the DC motor;

[0035] Step 4: Press the buttons respectively, the remote controller receives the signal and transmits it to the remote control circuit board, and the remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com