Forming mold for mobile phone rear cover blank with middle frame capable of adjusting movable mold cavities through springs

A technology of movable cavity and spring adjustment, which is applied in the field of blank forming molds, can solve problems such as uneven thickness, difficulty in forming, increase injection pressure and injection speed, etc., so that it is not easy to separate from each other, beautiful in appearance, and reduces costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

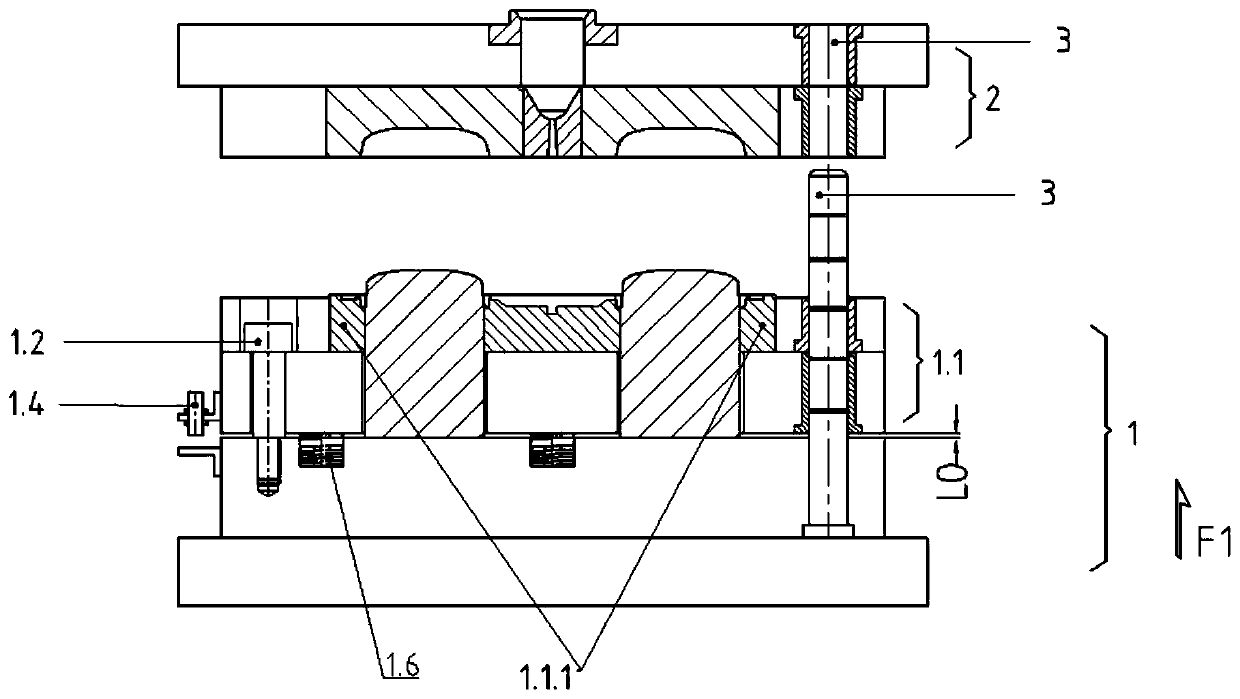

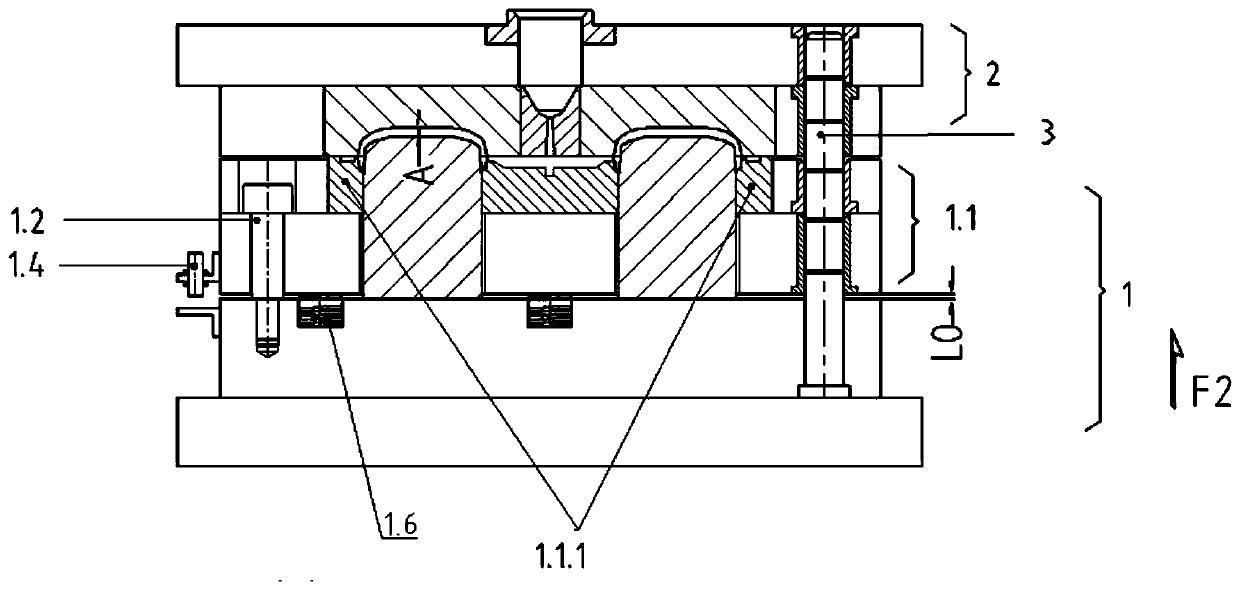

[0029]According to the invention, the mobile phone back cover blank material forming mold including the middle frame, which regulates the movable cavity by the spring, is suitable for producing the mobile phone back cover.

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 , describe in detail the preferred embodiment and other embodiments of the mobile phone back cover blank forming mold including the middle frame that regulates the movable cavity through the spring of the present invention.

[0031] The present invention provides a mobile phone back cover blank forming mold including a middle frame with a movable cavity adjusted by a spring, which includes a movable mold 1 and a fixed mold 2, the movable mold 1 is provided with a movable mold supporting device 1.10, and the fixed mold The mold is provided with a fixed mold suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com