Light-weight high-strength helicopter tail door structure

A high-strength, helicopter technology, applied in the direction of aircraft doors, fuselage, aircraft accessories, etc., can solve the problems of reducing the effective load and heavy weight, and achieve the effect of weight reduction, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

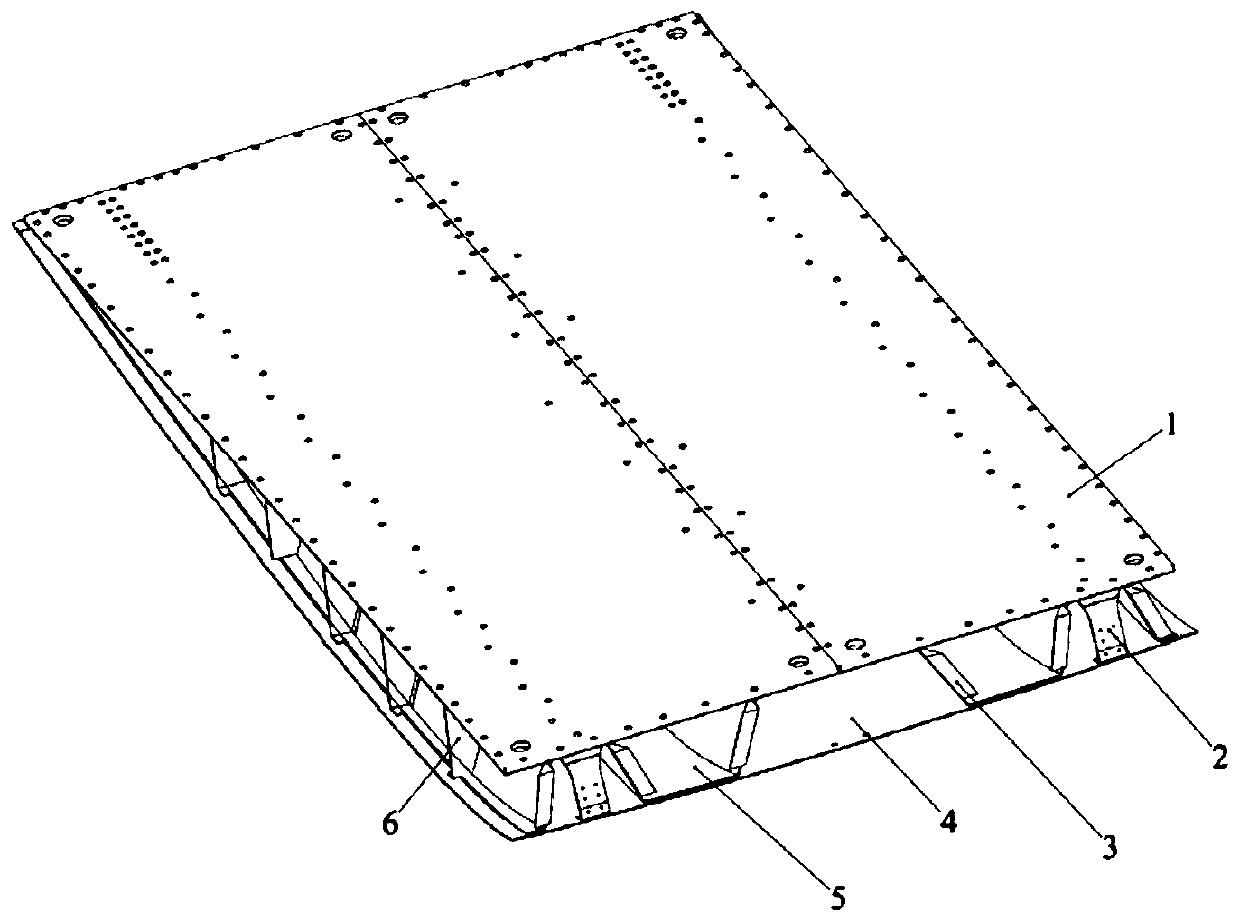

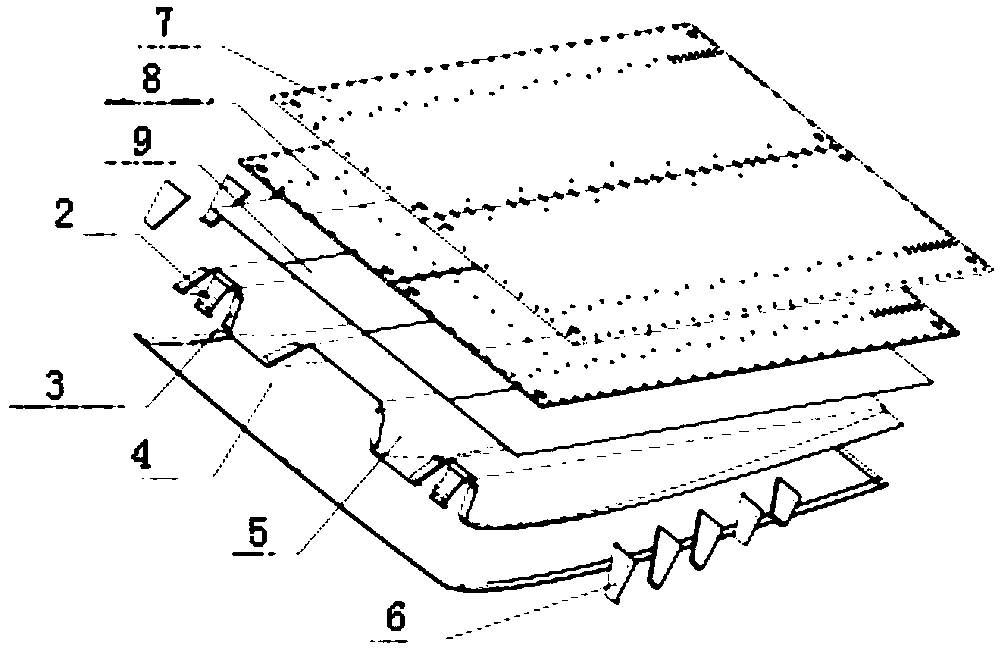

[0019] see figure 1 , the helicopter tailgate structure is mainly composed of floor 1, bottom skin 4 and composite material stiffened plate 5, see figure 2 , wherein the floor 1 is composed of an upper panel 7 , a honeycomb interlayer 8 and a lower panel 9 . The composite stiffened plate 5 is a plate with a rib structure. According to installation requirements, an installation angle material 2, an installation corner box 3 and an installation web 6 are riveted around the composite material stiffened plate 5 as an interface for installation with the fuselage. The bottom skin 4 covers the outermost side.

[0020] For the composite material stiffened plate 5, its rib structure is composed of the concave-convex structure of the plate itself, and the extending direction of the rib structure is longitudinal, and symmetrically distributed on the left and right sides of the fuselage symmetry axis, as the main load-bearing structure instead of the traditional machine-added frame be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com