Load projection mapping method for introducing stamping forming information into finite element simulation model

A simulation model and stamping forming technology, which is applied in the field of stamping and forming to achieve the effect of improving the simulation calculation accuracy and solving the contradiction between the solution accuracy and the model scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

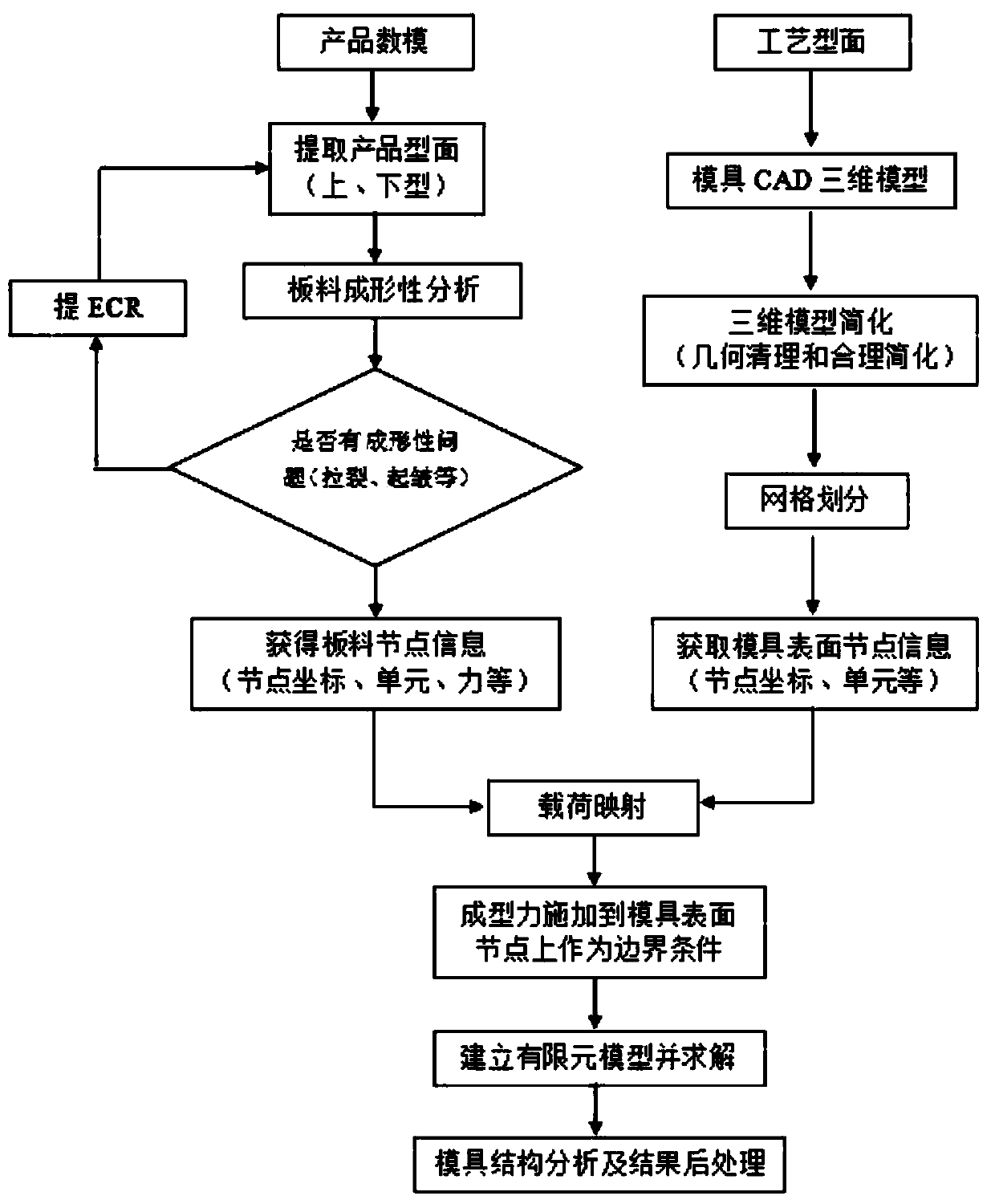

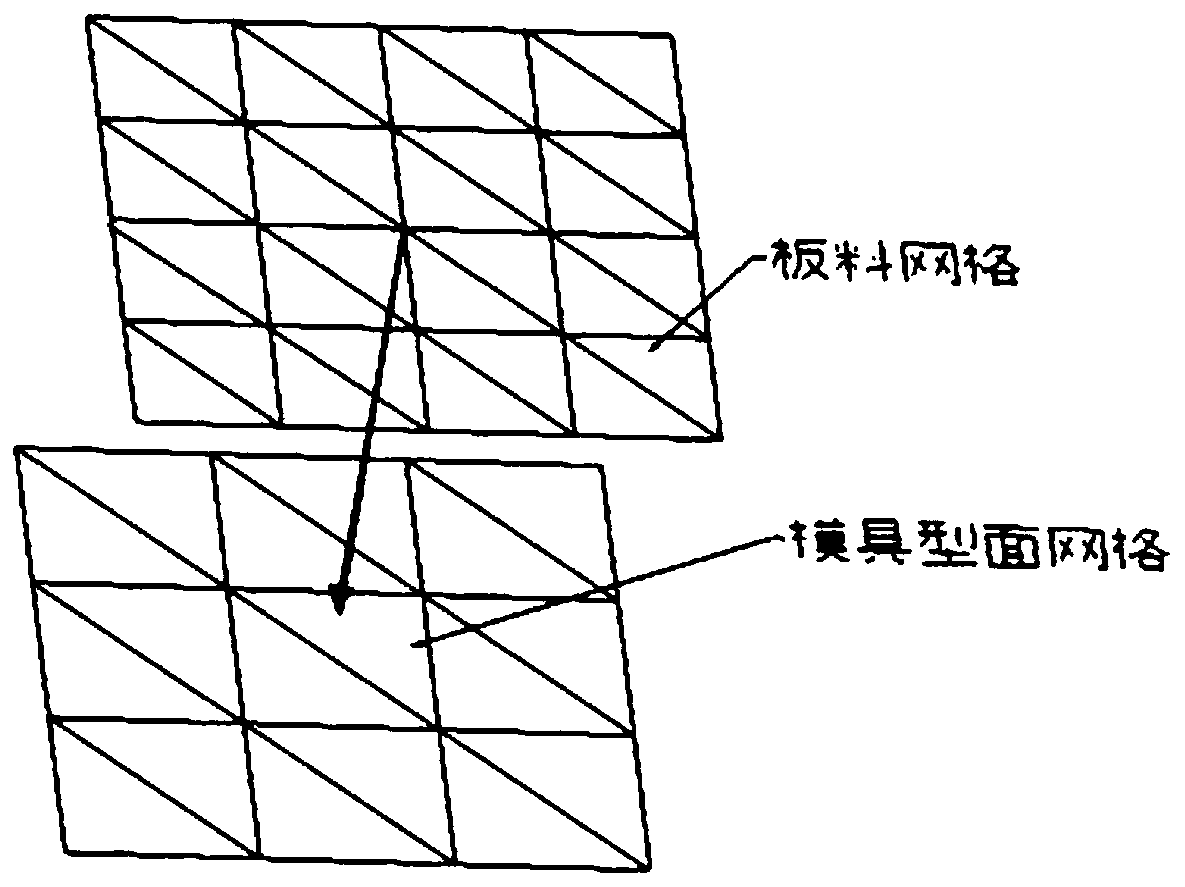

[0037] Such as Figure 1-7As shown, the load projection mapping method for introducing stamping forming information into the finite element simulation model provided by the present invention includes the following steps:

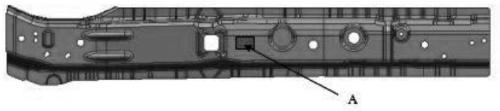

[0038] (1) Sheet material node information extraction: using Autoform as the numerical simulation platform, extract the product profile (upper and lower profile benchmarks) according to the product digital model provided by the product department, and import the product profile into Autoform to form the sheet metal According to the analysis results, it is judged whether the product has formability problems (such as cracking, wrinkling, etc.), if the product has formability problems, it is required to change the product, and then analyze the new product according to the feedback until there is no Formability problem, if the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com