Sliding contact power supply device and power supply method for gantry crane

A technology of power supply device and gantry crane, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of contact slider wear, failure of contact slider anti-corrosion protection, circuit virtual connection, etc., achieve continuous and stable power supply, and facilitate The effect of controlling the on-off of the circuit and quick lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

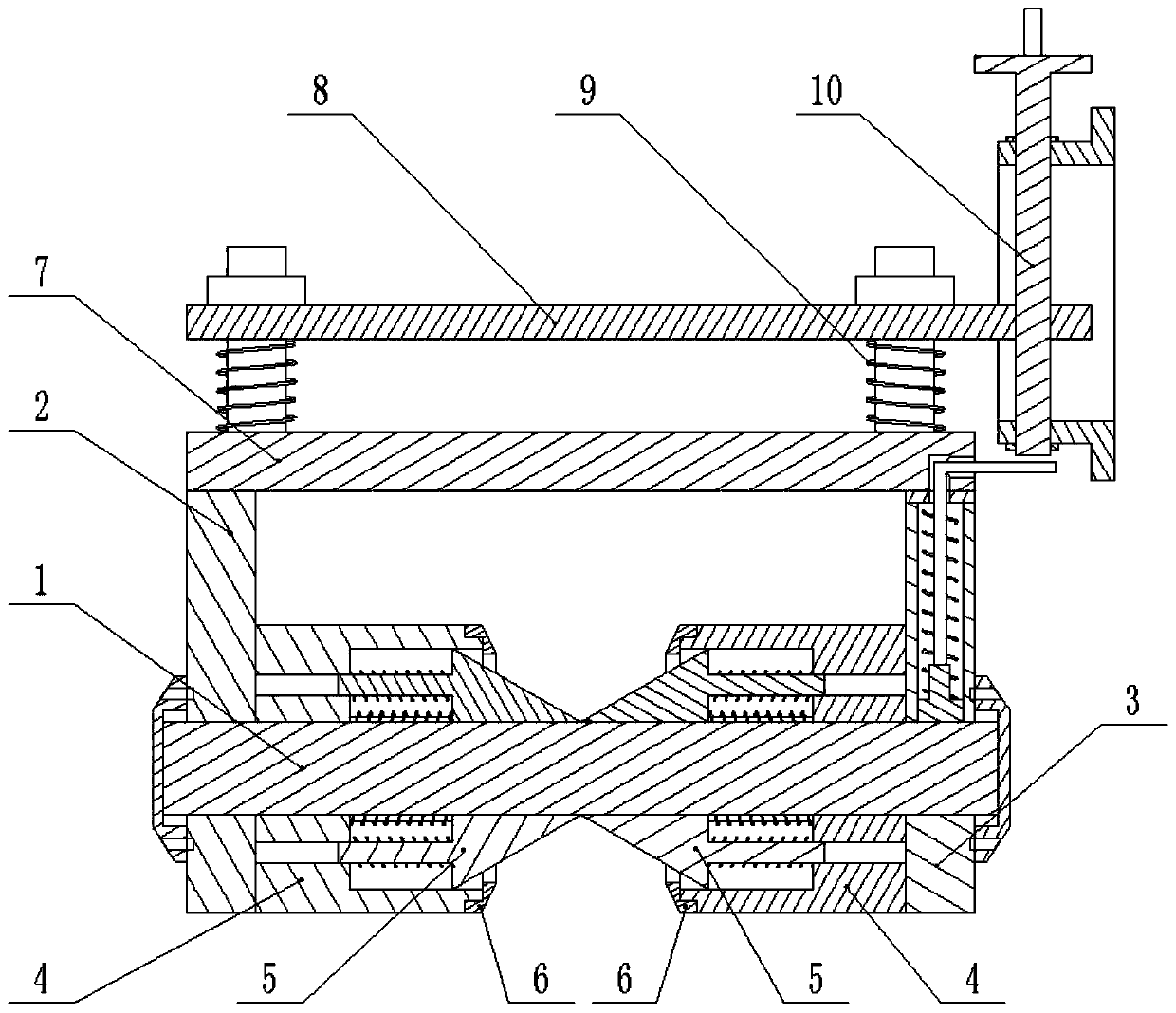

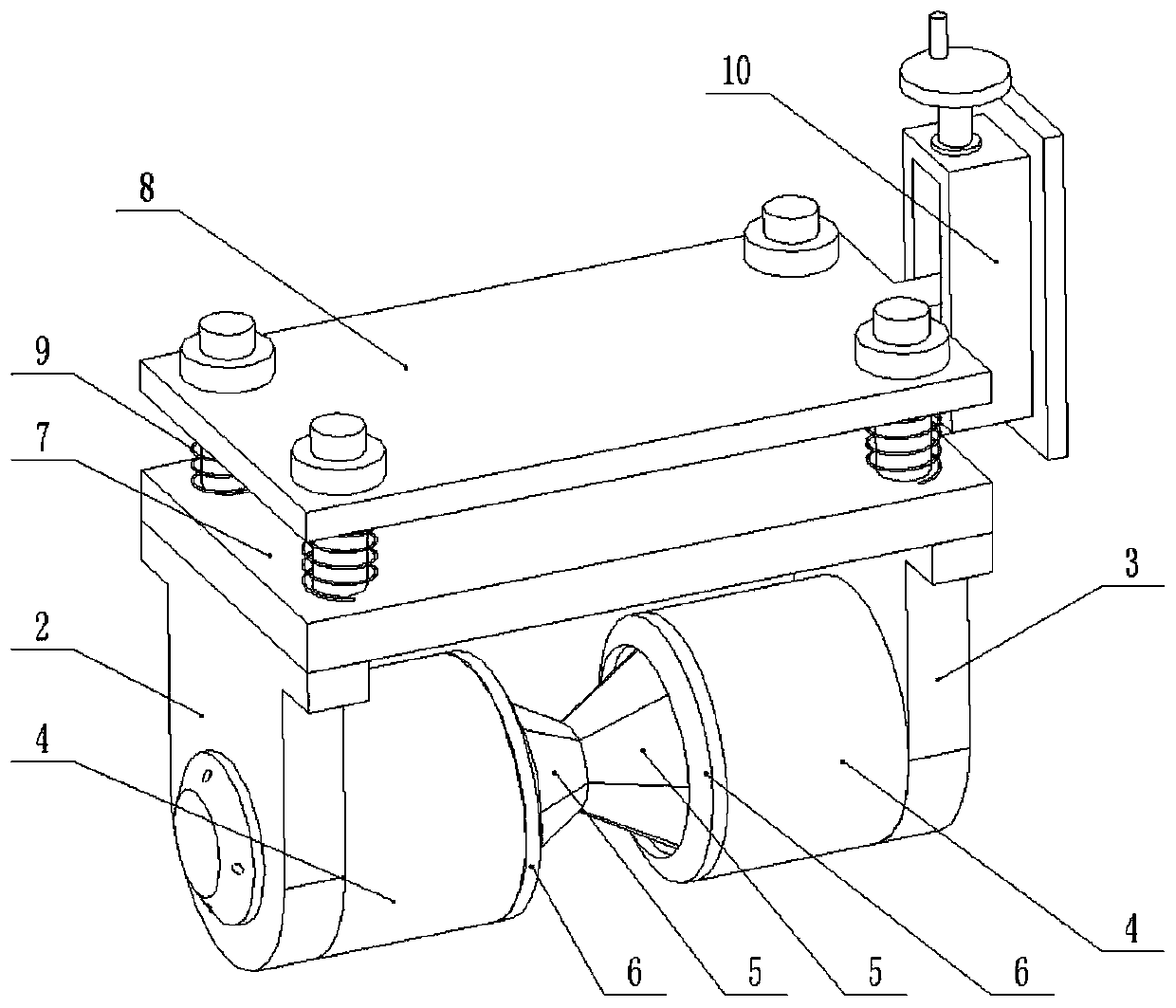

[0029] Combine below Figure 1-10 Description of this embodiment, the sliding contact power supply device and power supply method of the gantry crane, including the power connection shaft 1, the shaft frame I2, the shaft frame II3, the shaft sleeve 4, the tapered sealing part 5, the shaft sleeve end cover 6, the shaft bracket fixing part 7, The pressure plate 8, the pressure plate spring 9 and the lifting adjustment assembly 10, the left and right ends of the power-connected rotating shaft 1 are respectively rotatably connected to the axle frame I2 and the shaft frame II3, and the left and right ends of the electric-connected rotating shaft 1 are respectively fixedly connected with a shaft Sleeve 4, two shaft sleeves 4 are arranged opposite to each other, the inner ends of the two shaft sleeves 4 are slidingly connected with a plurality of conical closures 5, and the plurality of conical closures 5 are wrapped on the electric rotating shaft 1, and the shaft sleeves 4 The inner...

specific Embodiment approach 2

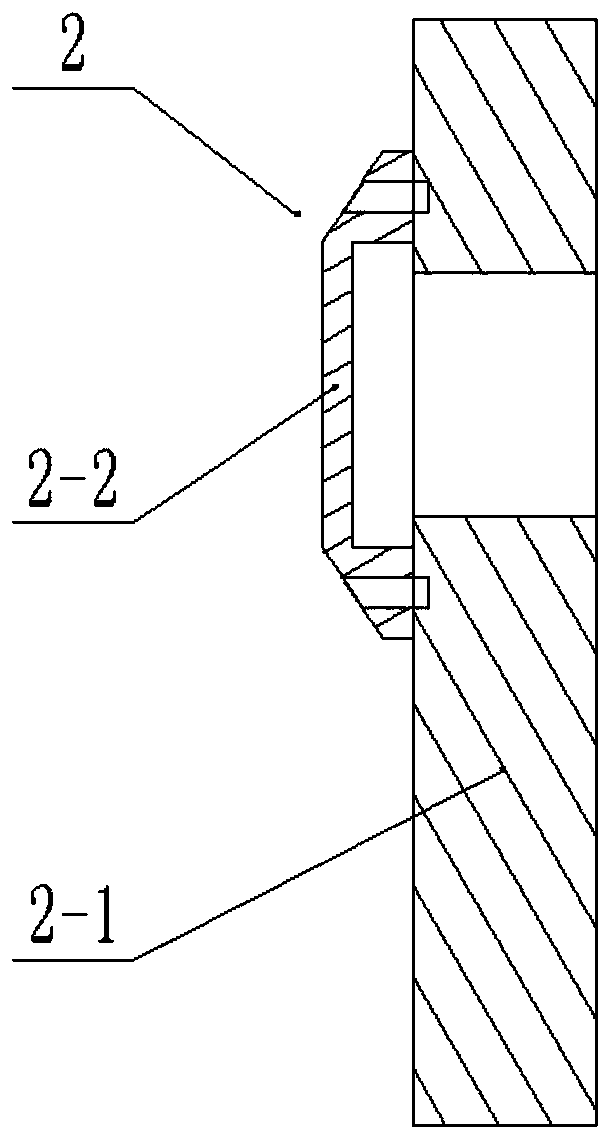

[0031] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 1, the axle frame I2 includes the axle frame body I2-1 and the axle frame end cover I2-2, and the axle frame end cover I2-2 is fixedly connected to the axle frame The outer end of the end cover I2-2, the shaft frame end cover I2-2 is used to seal the left end of the electric rotating shaft 1 .

specific Embodiment approach 3

[0033] Combine below Figure 1-10Describe this embodiment, this embodiment will further explain the first embodiment, the shaft frame II3 includes the shaft frame body II3-1, the shaft frame end cover II3-2, the shaft hole 3-3, the wire hole 3-4, the brush 3-5, wire 3-6, upper end cover 3-7 and brush spring 3-8, the axle frame end cover II3-2 is fixedly connected to the outer end of the axle frame body II3-1, the axle frame body II3 -1 is provided with a shaft hole 3-3 penetrating left and right, and the shaft frame body II 3-1 is provided with a vertical wire hole 3-4, and the shaft hole 3-3 communicates with the wire hole 3-4. The electric connecting shaft 1 is rotatably connected in the shaft hole 3-3, the electric brush 3-5 is slidably connected in the wire hole 3-4, the electric brush 3-5 is in contact with the electric rotating shaft 1, and the electric brush The upper end of 3-5 is fixedly connected to the wire 3-6, the upper end cover 3-7 is fixedly connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com