Manufacturing process of preform

A manufacturing process and prefabricated rod technology, which is applied in the field of preformed rod manufacturing technology, can solve the problems of reducing processing efficiency and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

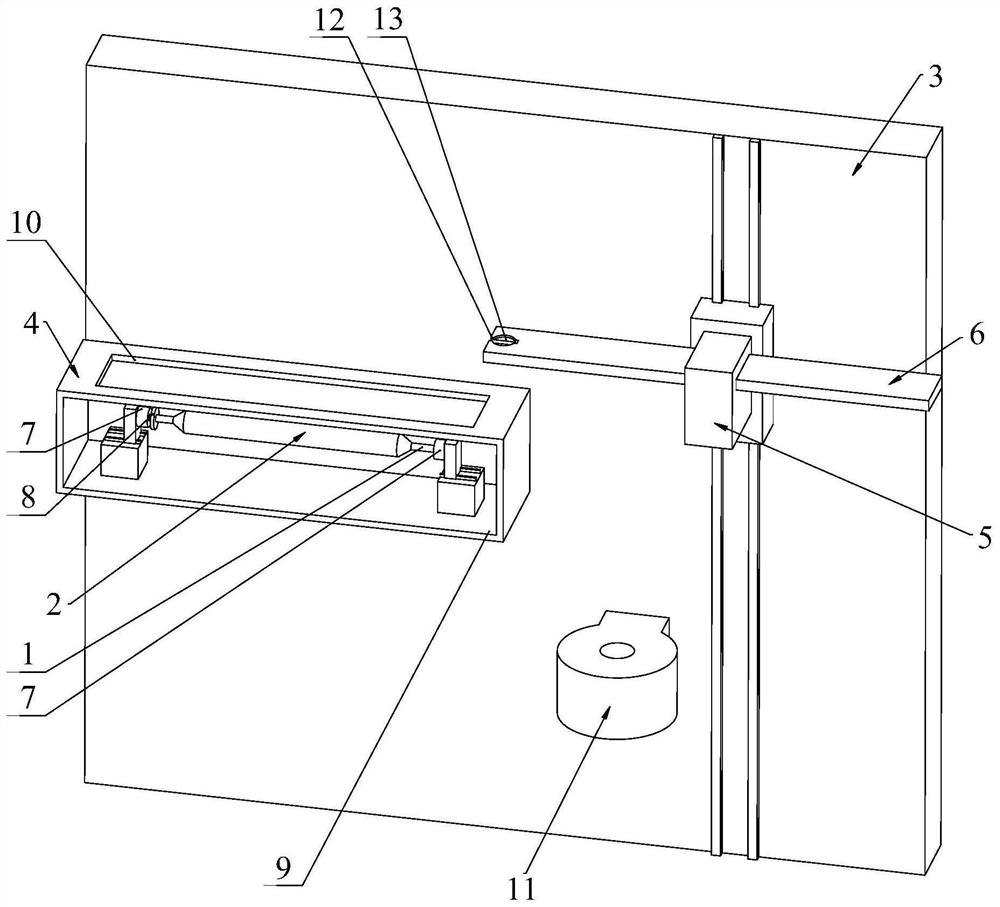

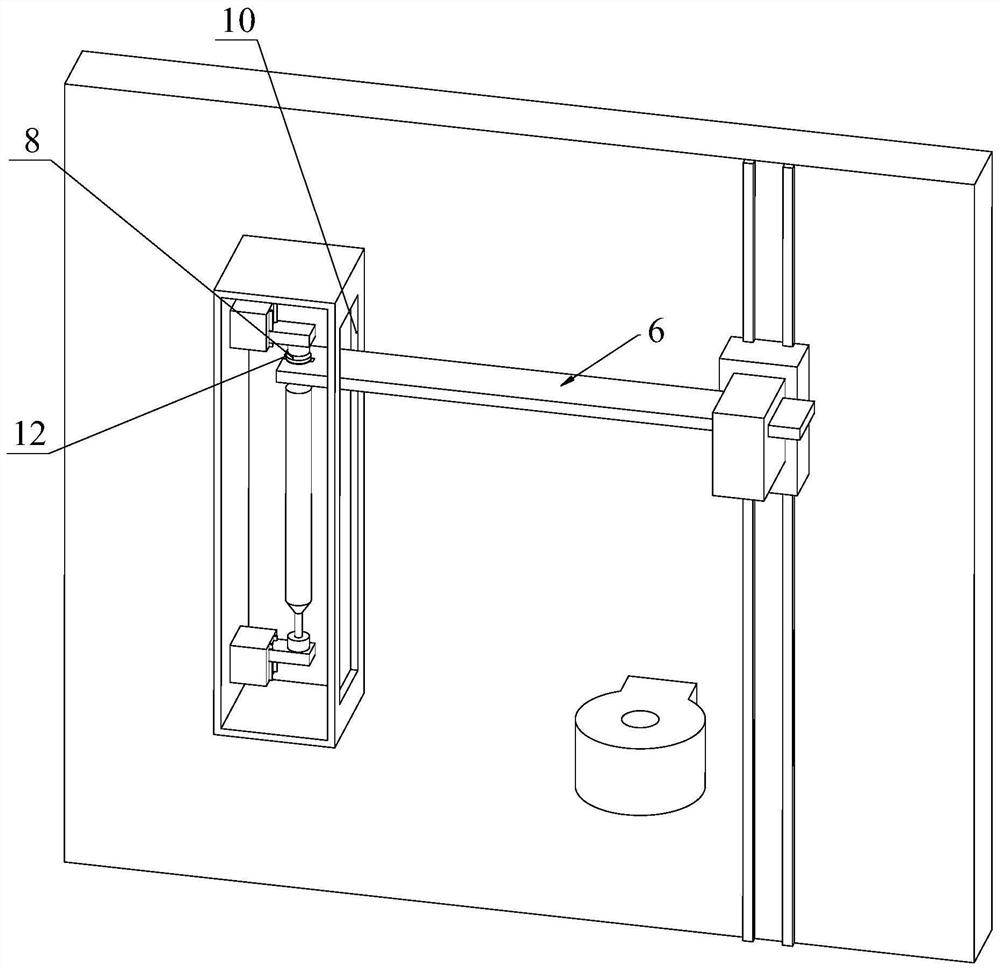

[0039] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0040] A manufacturing process for a preform, comprising the following steps:

[0041] 1) The mandrel is installed on the two rotating chucks of the deposition bed to carry out the deposition operation of the loose body;

[0042] 2) After the deposition operation is completed, the deposition bed is rotated 90° so that the loose body is vertically arranged;

[0043] 3) The loose body is removed from the deposition bed, and moved into a heating furnace for sintering operation to obtain a preform.

[0044] In the manufacturing process of the present application, after the deposition of the loose body is completed, the deposition bed is rotated 90° so that the loose body is vertical, and the loose body can be quickly vitrified (sintering operation) after the loose body is removed, thereby greatly improving the processing efficiency.

[0045] In this embodiment, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com