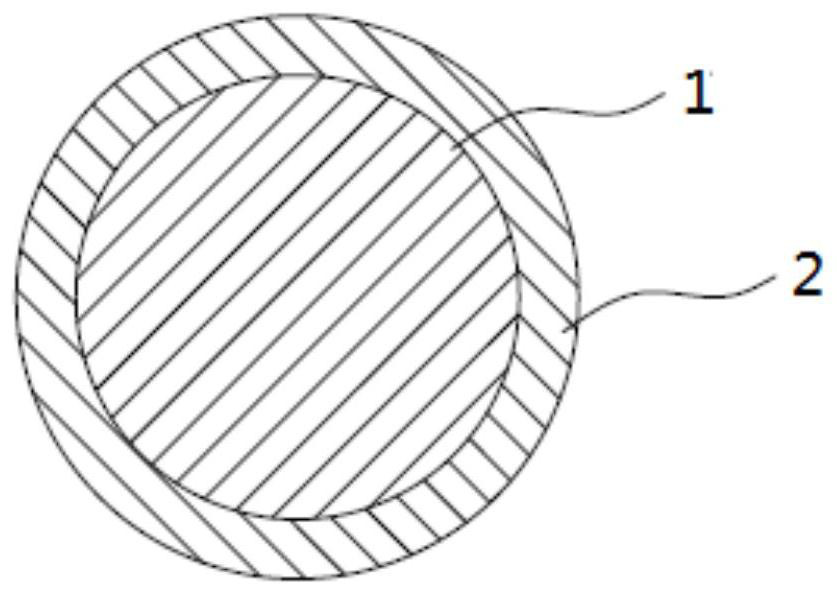

Solid thermosetting phenolic resin with core-shell structure and preparation method thereof

A technology of phenolic resin and core-shell structure, applied in the field of phenolic resin, can solve the problems of needing to be crushed, easy to soften and agglomerate, and achieve the effect of preventing softening and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

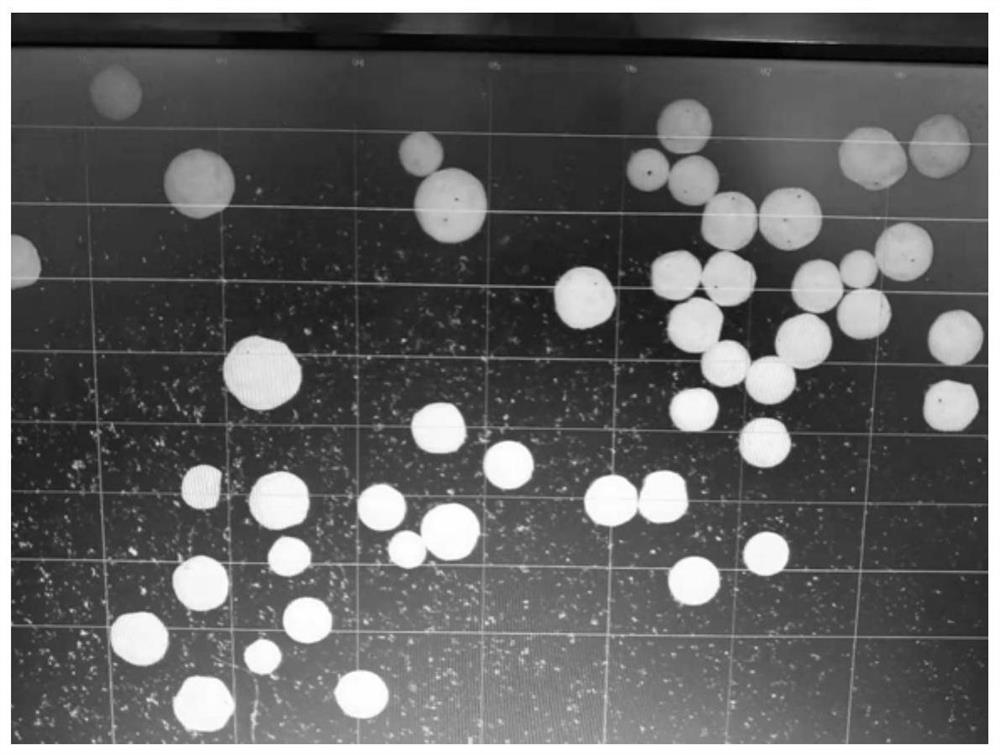

Examples

Embodiment 1

[0028] Put 100g of hydroxymethylcellulose and 600g of water into the reaction kettle, and the temperature is raised to 90°C. After the hydroxymethylcellulose is completely dissolved, put in KH550 that accounts for 60% of the weight of hydroxymethylcellulose and stir evenly. Under the condition of 90°C, after reacting for 1 hour, the obtained product was discharged and then cooled to obtain a colloidal solution a.

[0029] Measure 600g of hot melted phenol into the reactor with a special pump, then add 775g of formaldehyde solution (34%) and 10g of ammonia solution, (in no particular order of feeding) raise the temperature to 70°C-75°C for reaction, when the system solution appears When a white liquid appears, add 60 g of the modified colloidal solution a, continue to react for 4 hours, then discharge the material, remove moisture by filtration after cooling, and freeze-dry to obtain a solid thermosetting phenolic resin.

Embodiment 2

[0031] Measure 600g of hot melted phenol into the reactor with a special pump, then add 775g of formaldehyde solution (34%) and 10g of ammonia solution, (in no particular order of feeding) raise the temperature to 70°C-75°C for reaction, when the system solution appears When a white liquid appears, add 120 g of modified protective colloid solution, continue to react for 4 hours, then discharge, remove moisture by filtration after cooling, and freeze-dry to obtain a solid thermosetting phenolic resin.

Embodiment 3

[0033] Put 100g of hydroxymethylcellulose and 600g of water into the reaction kettle, and the temperature is raised to 90°C. After the hydroxymethylcellulose is completely dissolved, add KH550 that accounts for 80% of the weight of hydroxymethylcellulose and stir evenly. Under the condition of 90° C., after reacting for 1 hour, the prepared product was discharged and then cooled to obtain a protective colloid solution b.

[0034] Measure 600g of hot melted phenol into the reactor with a special pump, then add 775g of formaldehyde solution (34%) and 10g of ammonia solution, (in no particular order of feeding) raise the temperature to 70°C-75°C for reaction, when the system solution appears When a white liquid appears, add 60 g of the modified protective colloid solution b, continue to react for 4 hours, then discharge the material, remove moisture by filtration after cooling, and freeze-dry to obtain a solid thermosetting phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com