An anti-shedding automatic cleaning sliding door and window

A technology for automatic cleaning and sliding doors and windows, which is applied to door/window accessories, special equipment for doors/windows, windows/doors, etc. It can solve the problems of reduced service life, danger to the lives of passers-by downstairs, increased friction between sliding windows and rails, etc. problem, to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

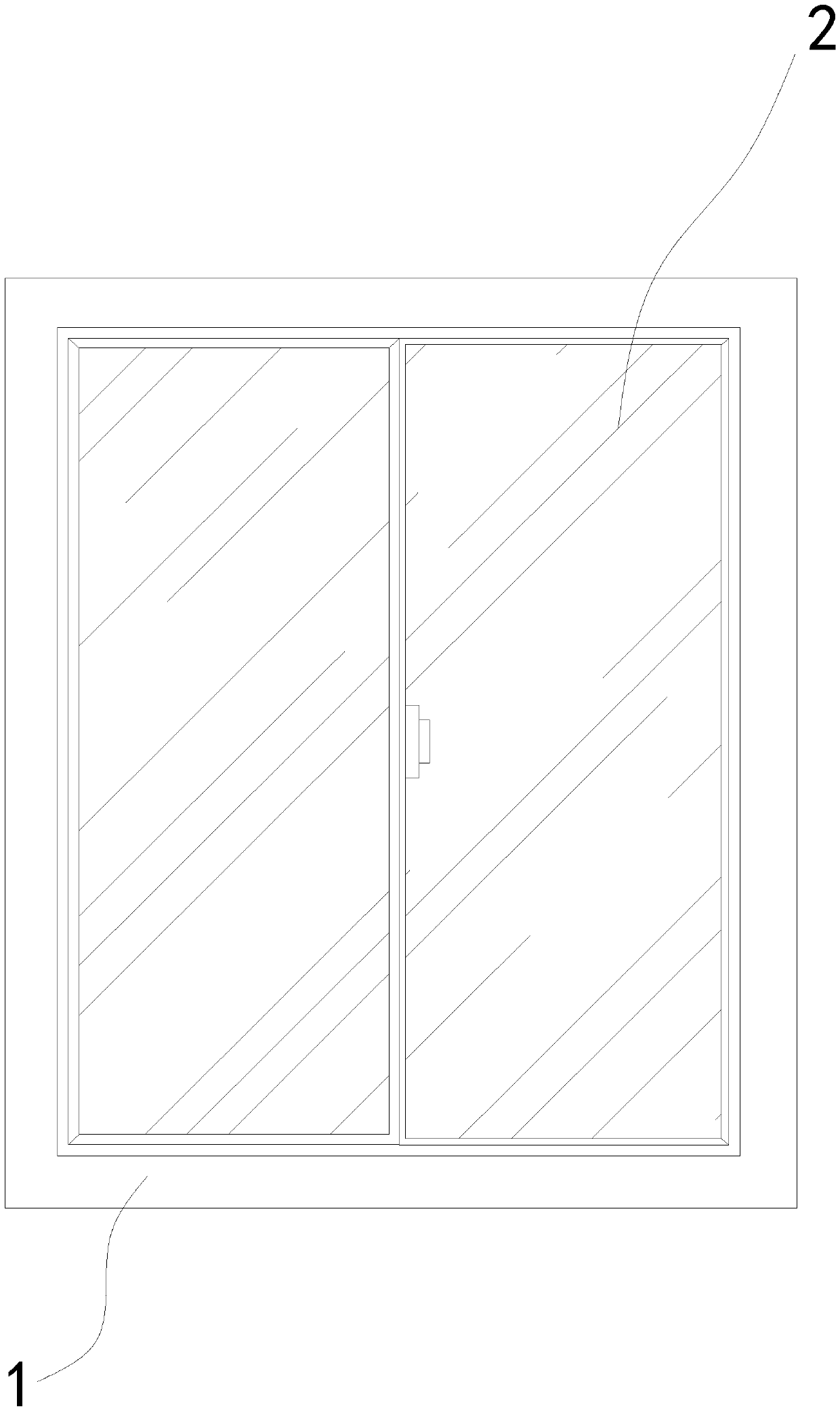

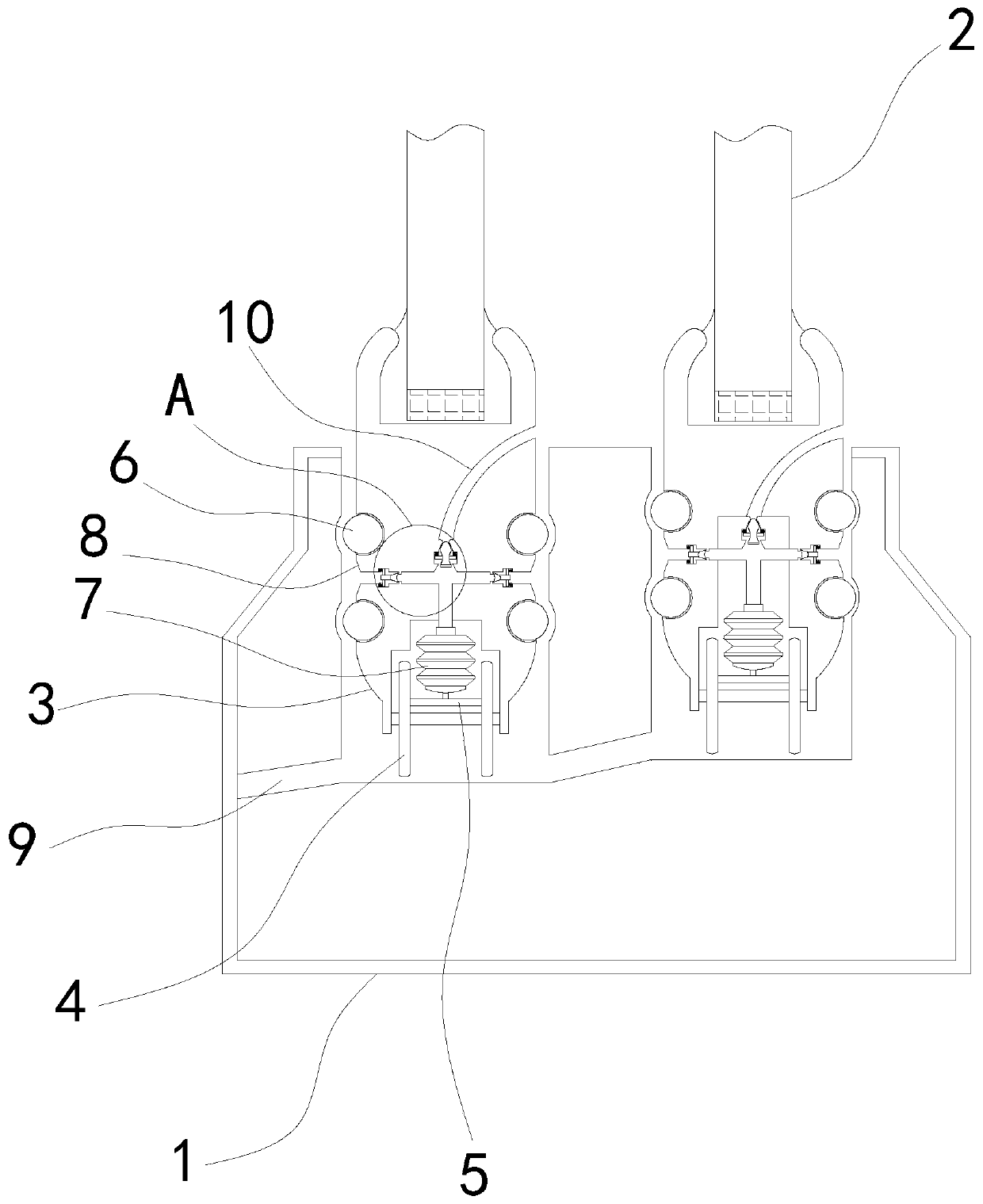

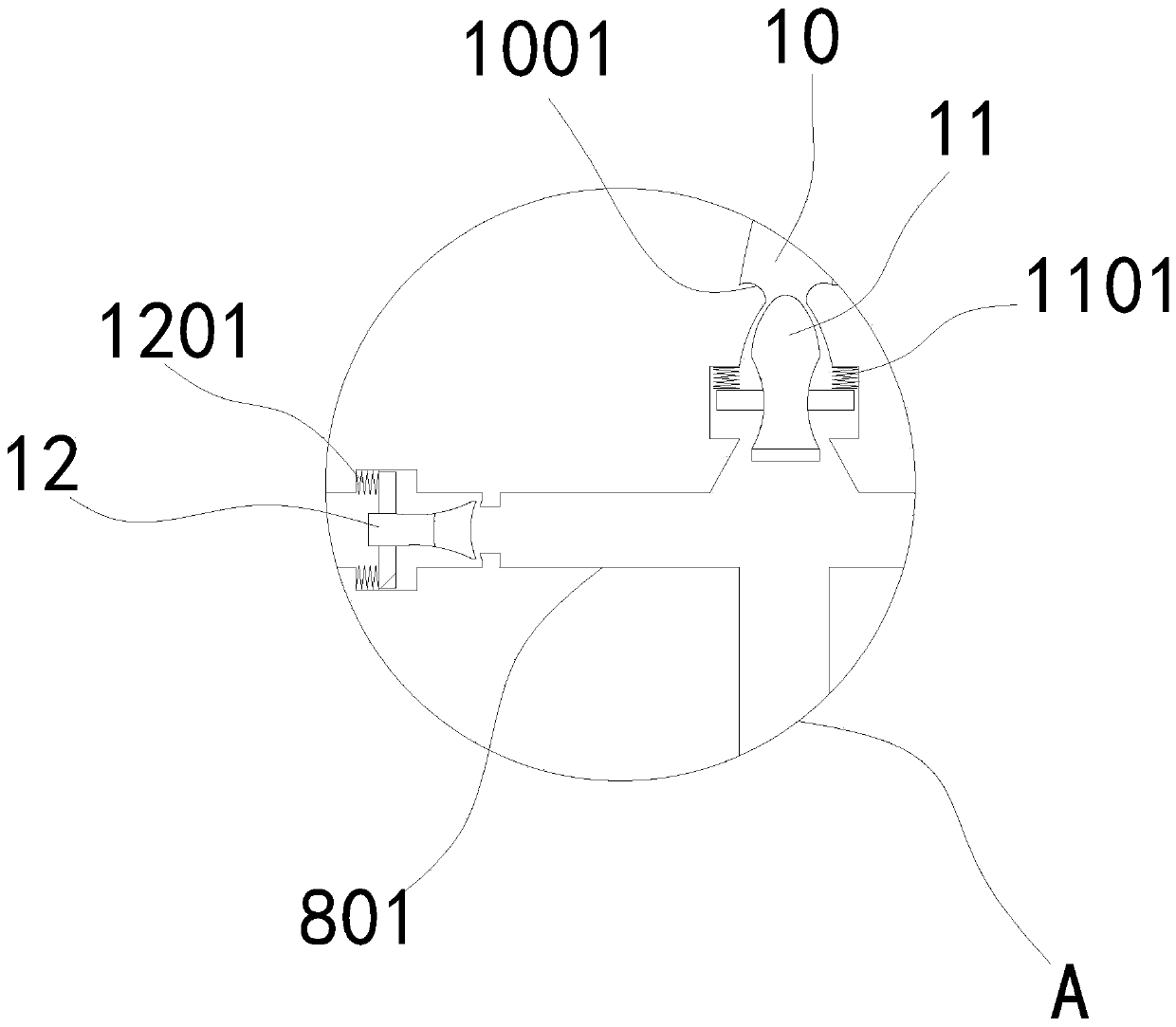

[0028] see Figures 1 to 8 , a schematic plan view and a three-dimensional structure view of an anti-shedding automatic cleaning sliding door and window.

[0029] An anti-shedding automatic cleaning sliding door and window, comprising a frame outer groove 1 and a sliding window 2, characterized in that: a ball moving groove 101 is provided on the inner side of the frame outer groove 1, and a frame base 3 and a frame base 3 are movably installed in the frame outer groove 1 The upper end is fixedly connected with a push-pull window 2, the inner lower end of the frame base 3 is movably connected with a runner 4, the inner side of the runner 4 is provided with a groove 401, and an extrusion airbag 7 is fixedly installed above the runner 4, and the lower end of the extrusion airbag 7 is fixedly connected with a The moving rod 5, the outer sides of the frame base 10 are movable with anti-falling balls 6, and the upper end of the frame base 3 is provided with an air inlet 10:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com