Shallow-buried tunnel pipe-roof underground excavation full-section construction method under complicated environmental conditions

A technology for shallow buried tunnels and complex environments, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of poor construction safety and surface settlement control, long distance, long distance between the secondary lining and the tunnel face, etc. Achieve significant economic and social benefits, enhance safety and stability, and travel safely and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

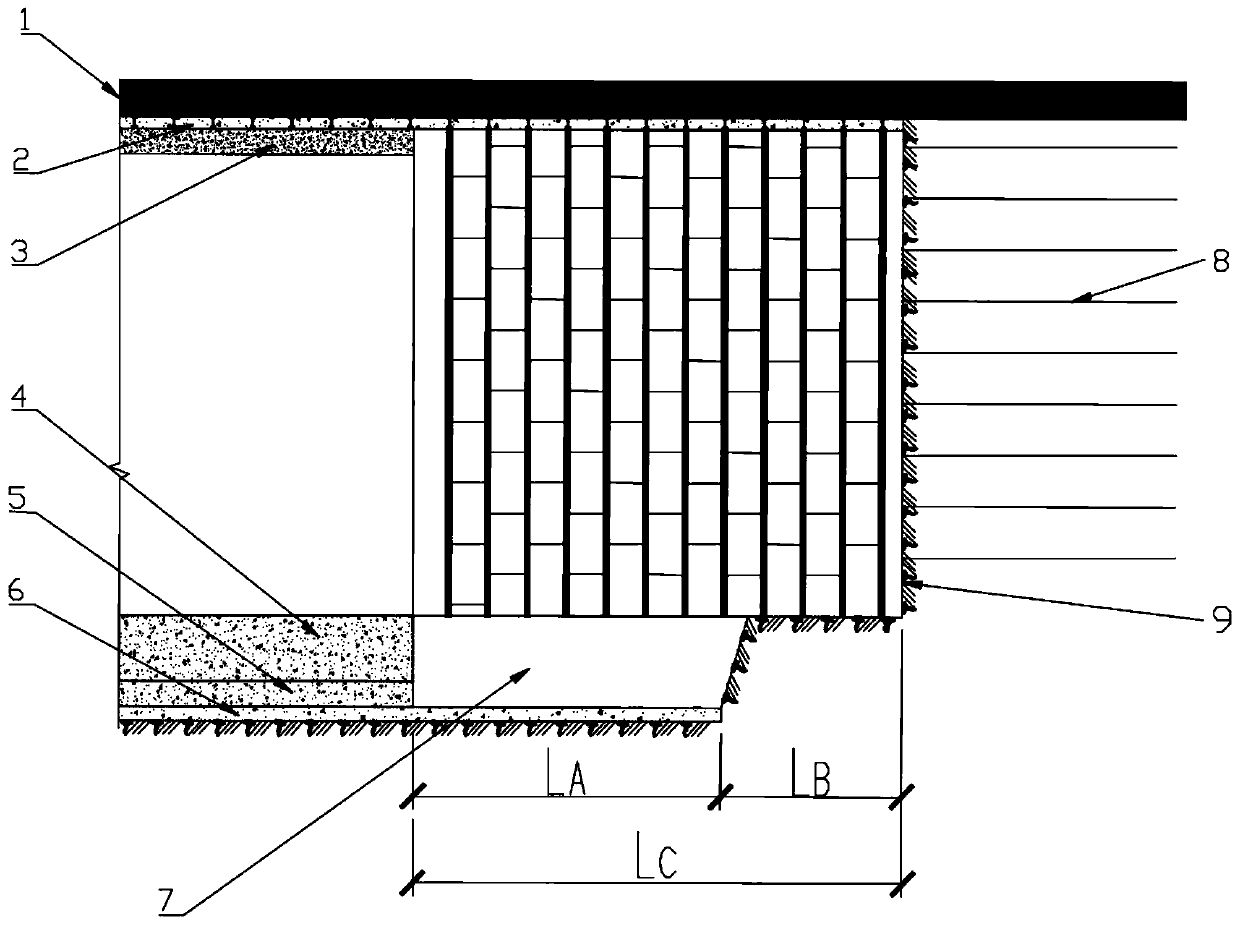

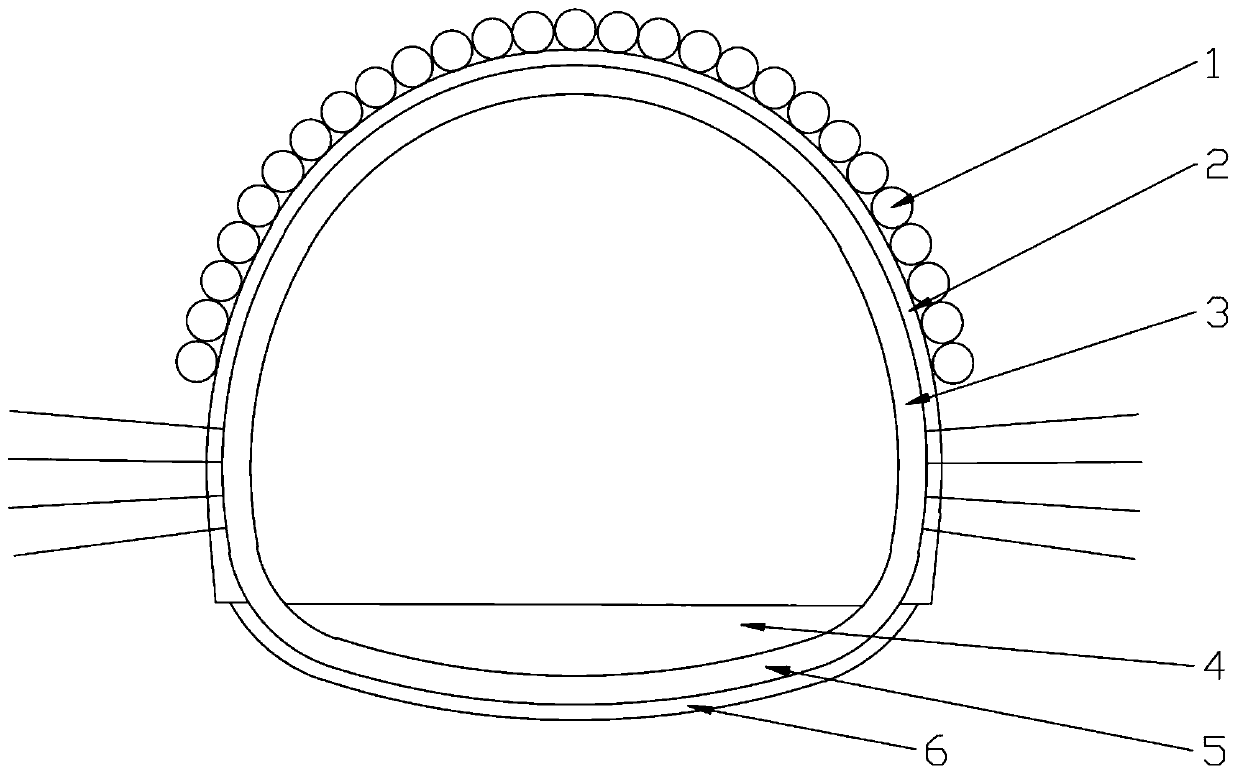

[0032] as attached figure 1 , 2 As shown in Fig. 1, a full-section construction method of pipe-curtain excavation for shallow-buried tunnels under complex environmental conditions,

[0033] Include the following steps:

[0034] S1. Install the pipe curtain 1 on the outside of the initial steel frame of the tunnel to form a super strong advance support;

[0035] S2. After the excavation of the full section of the tunnel is completed, the initial support of the arch wall area will be applied 2;

[0036] S3. After the excavation of the tunnel inverted arch bottom 7 is completed, the initial support 6 of the inverted arch area is applied;

[0037] S4. Complete the second lining of the whole ring and the inverted arch filling 4 concrete pouring;

[0038] In order to shorten the distance between the tunnel face 9 and the second lining, take the following measures:

[0039] a. Shorten the space distance between each process. The distance LA of the inverted arch bottom picking 7 ...

Embodiment 2

[0047] Optimally, in Embodiment 1, in order to further improve the effect of surface subsidence control or to meet the stability requirements of face excavation, if necessary, there may also be a step between steps S1 and S2: S102, in order to further improve the surface subsidence control To achieve or solve the stability requirements of tunnel excavation, the tunnel excavation tunnel face 9 is reinforced by advanced grouting bolts 8 to ensure the self-stabilization ability of the tunnel excavation tunnel face 9 during tunnel construction.

Embodiment 3

[0049] Optimally, in Embodiment 1, in order to shorten the distance between the tunnel excavation face 9 and the second lining as much as possible, the following measures can also be taken: when necessary, under the protection of the super-strong pipe curtain 1, pass through the tunnel excavation face The subface 9 is reinforced to achieve the stability of the tunnel excavation subface 9 and better settlement control effect under the condition of full-section excavation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com