a pipe fitting

A technology of pipe fittings and pipe bodies, applied in the field of pipe fittings, can solve the problems of broken pipe fittings, poor pressure resistance, a large amount of water, etc., and achieve the effect of reducing the size of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

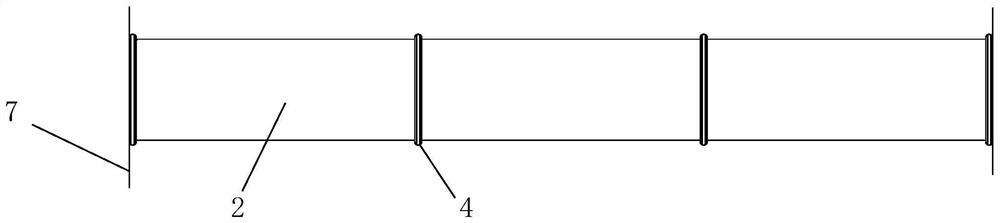

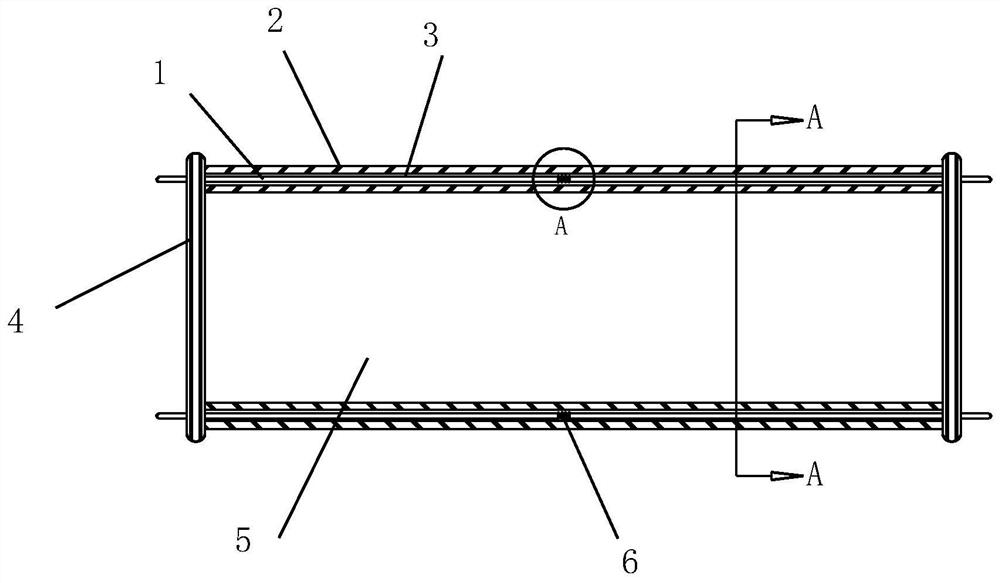

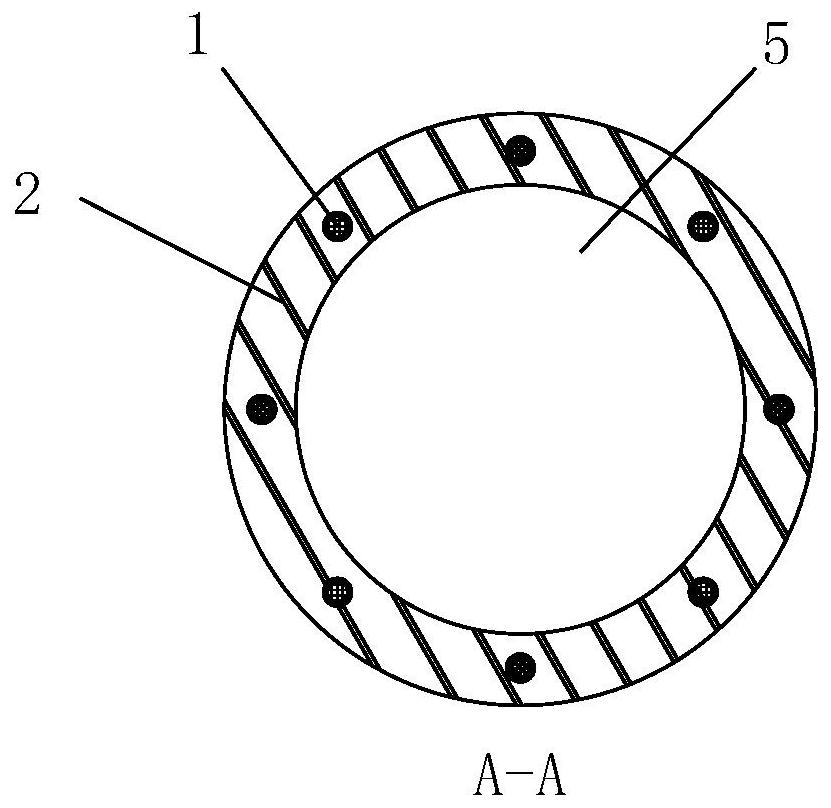

[0019] Such as figure 1 As shown, first of all, it is necessary to limit the two sides of the buried pipe fitting body, so that the length of the pipe fitting can be compressed. The pipe fitting body specifically includes more than one section of pipe body 2 and more than one expansion connector 4;

[0020] The main body of the pipe fitting is buried in a pre-embedded cavity 7 that is limited on both sides, and an expansion joint 4 is installed between adjacent pipe bodies 2, and the pipe bodies 2 on both sides are connected through the expansion joint 4. The total length of the entire pipe fitting main body is If it is longer than the length of the pre-embedded cavity, the expansion connector of the whole pipe fitting body is extruded and embedded in the pre-embedded cavity and passes through the pre-embedded cavity to limit both sides. The extruded expansion connector protrudes outward and A supporting ring is formed to contact and support the bottom surface of the pre-embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com